Method for measuring radial dynamic flexibility of rolling bearing

A technology of rolling bearings and dynamic flexibility, which is applied in the field of mechanical engineering, can solve the problems of expanding test result errors, test result errors, poor precision, etc., and achieve the effects of ensuring time consistency, easy method, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

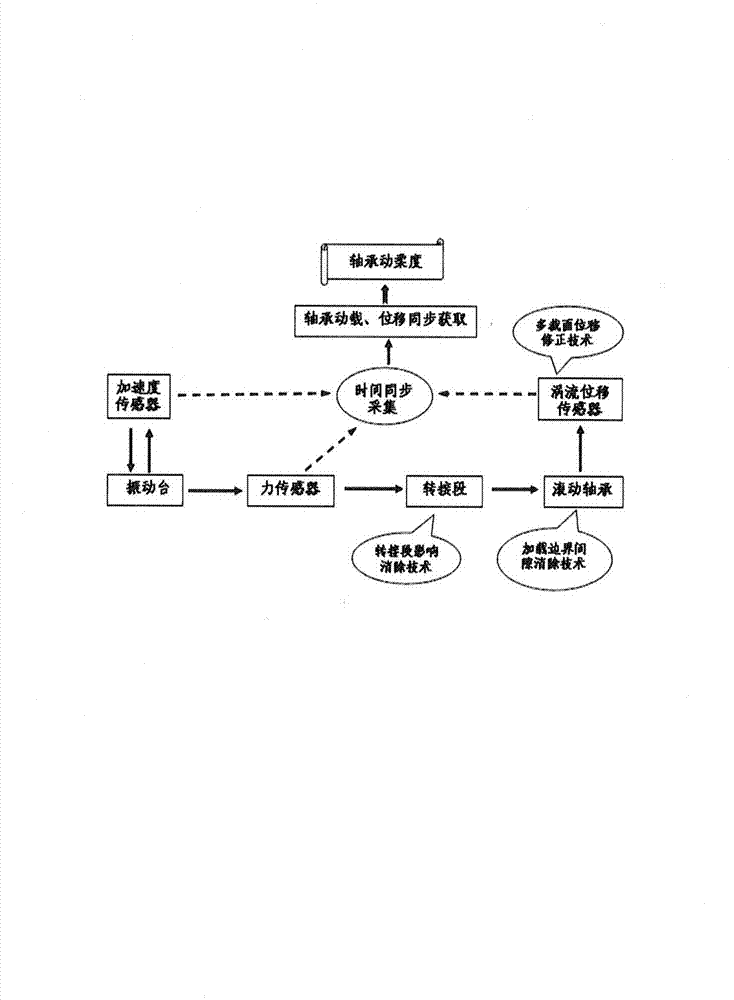

[0034] The radial dynamic compliance of rolling bearings can be defined as the radial displacement under the unit dynamic load of the bearing, that is, the acquisition of dynamic compliance requires the measurement of two parameters, dynamic load and radial displacement. In order to obtain the high-precision measurement value of the dynamic compliance of the bearing through the test, it is best to be able to directly load the dynamic excitation, and at the same time realize the simultaneous and direct measurement of the dynamic load and displacement of the bearing.

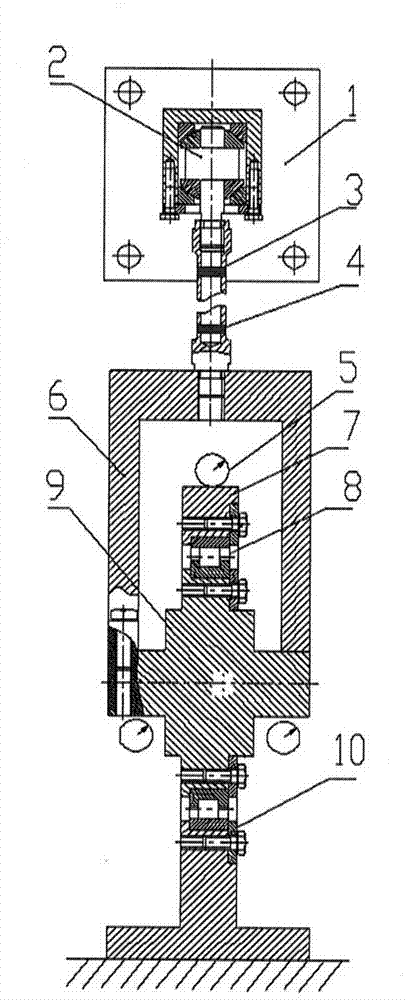

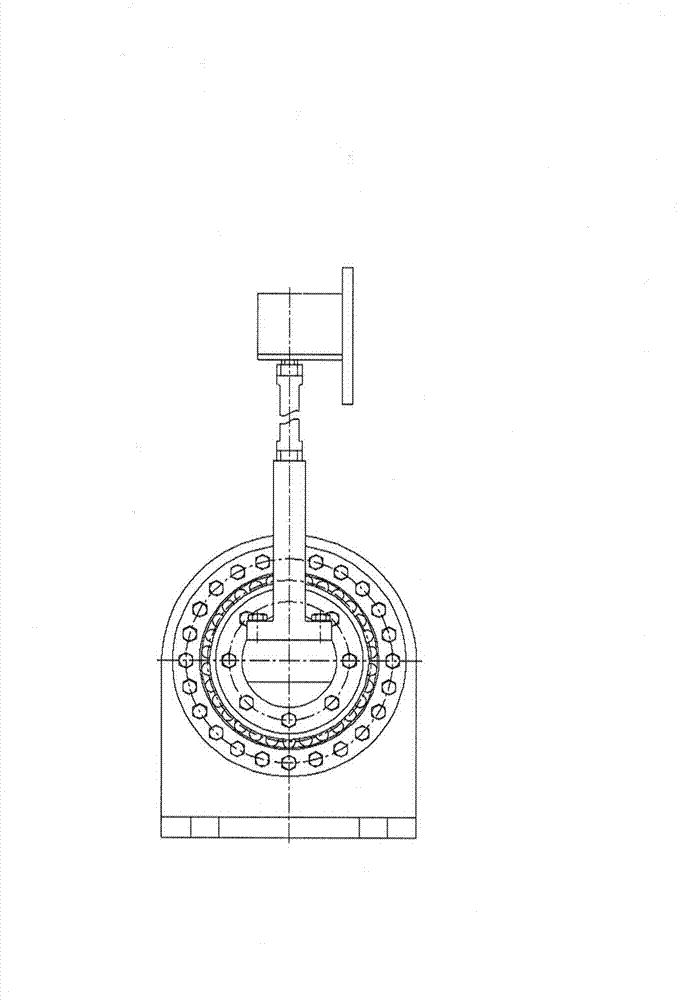

[0035] like figure 1 As shown in the figure, the test bench used to measure the radial dynamic compliance of rolling bearings is described, including the vibration table 1, which directly applies the dynamic load to the inner ring of the bearing through the transfer section, and the transfer section includes a universal joint 2. Connecting rod, radial force loading gantry 6 and dummy shaft 9. One end of the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com