A method for manufacturing a light-emitting diode wire electrode

A technology of light-emitting diodes and wire-bonded electrodes, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of affecting the quality of light-emitting diodes, the bonding force between leads and electrodes cannot be greatly improved, and off-lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] see Figure 1-5 The method for manufacturing the wire-bonding electrodes of the light-emitting diode proposed by the present invention is introduced.

[0019] see Figure 1-2 , the manufacturing method of light-emitting diode bonding electrode comprises the following steps:

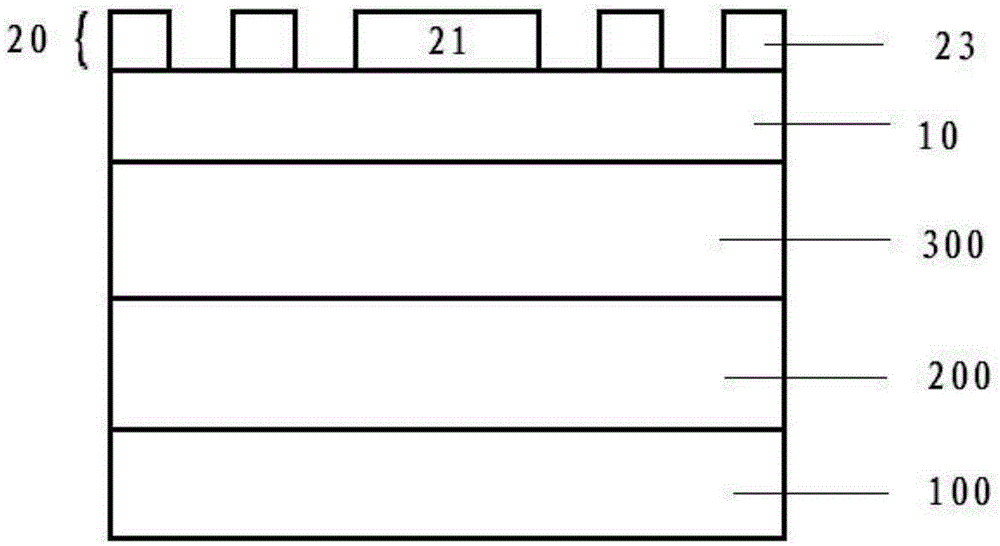

[0020] (1) Forming the p-type semiconductor layer 100 , the semiconductor light-emitting layer 200 and the n-type semiconductor layer 300 sequentially from bottom to top;

[0021] (2) forming a transparent flat electrode 10 on the n-type semiconductor layer 300;

[0022] (3) Evaporating a metal alloy layer on the flat electrode 10;

[0023] (4) performing photolithography and etching processes on the alloy metal layer, so as to form the metal alloy layer into bump electrodes 20 ;

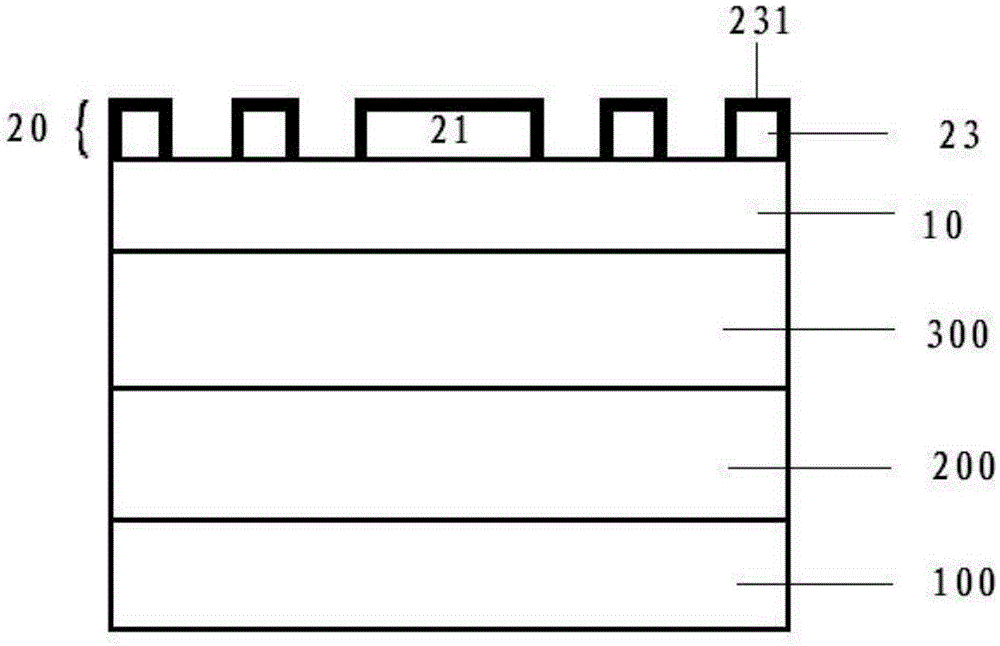

[0024] (5) Roughen the upper surface and all side surfaces of the bump electrode 20 to form a bump roughened electrode 201

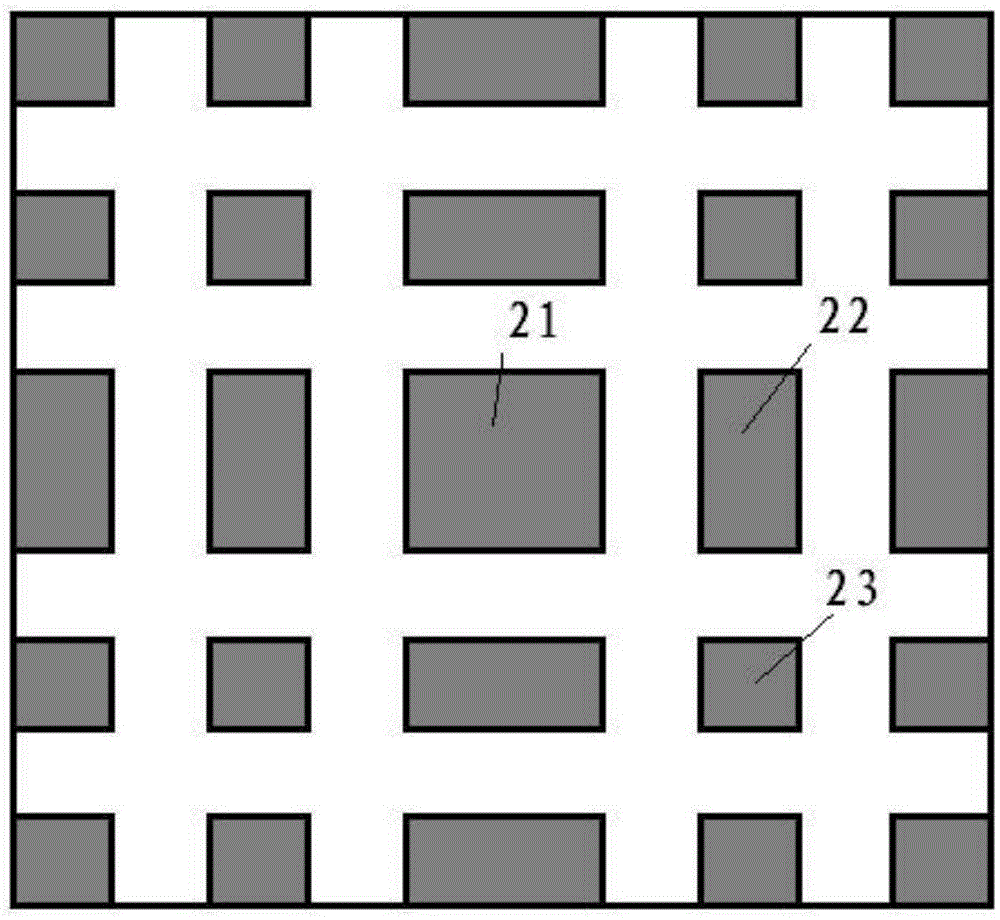

[0025] see image 3 ,Should image 3 It shows the top view of the electrode produced by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com