Automatic cigarette bar supplementing system of GD cigarette bar transparent paper packager

A packaging machine, a transparent technology, applied in packaging automatic control, packaging, packaging protection, etc., can solve problems such as motor damage, missing filling time, packaging quality impact, etc., to achieve the effect of improving work efficiency and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

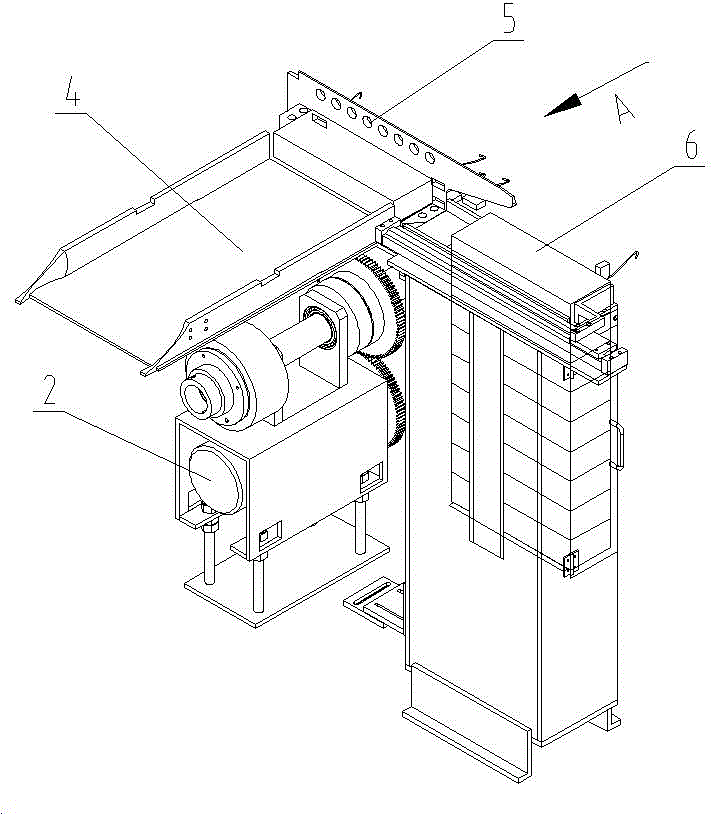

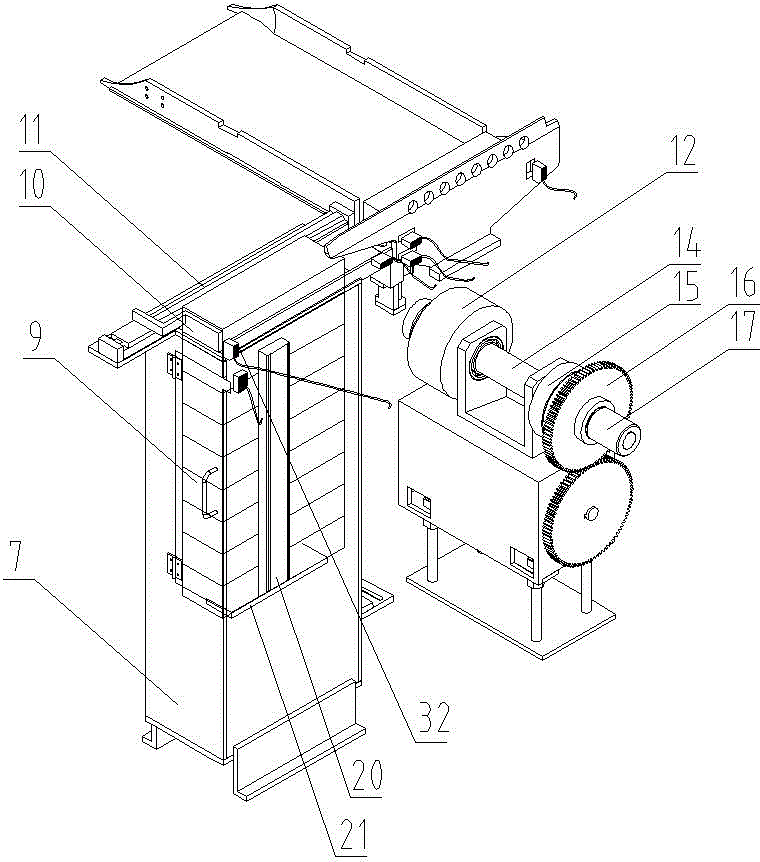

[0037] Such as figure 1 , figure 2 and image 3 As shown, the automatic cigarette filling system of the GD cigarette rod transparent paper packaging machine in this embodiment, wherein the auxiliary machine of the GD packaging machine includes three parts: a small box transparent paper packaging machine, a carton packaging machine and a carton transparent paper packaging machine. The power output shaft of the carton packaging machine and the power input shaft of the carton transparent paper packaging machine are connected through a coupling. When the auxiliary machine is working normally, the tobacco rods are conveyed to the lifting plate through the U-shaped conveying channel 4 of the carton transparent paper packaging machine. Tobacco stick transparent paper packaging machine intake. The automatic cigarette filling system in this embodiment includes a smoke storage box 7, a horizontal smoke pushing device, a power source 2, a power switching device, and a detection and co...

Embodiment 2

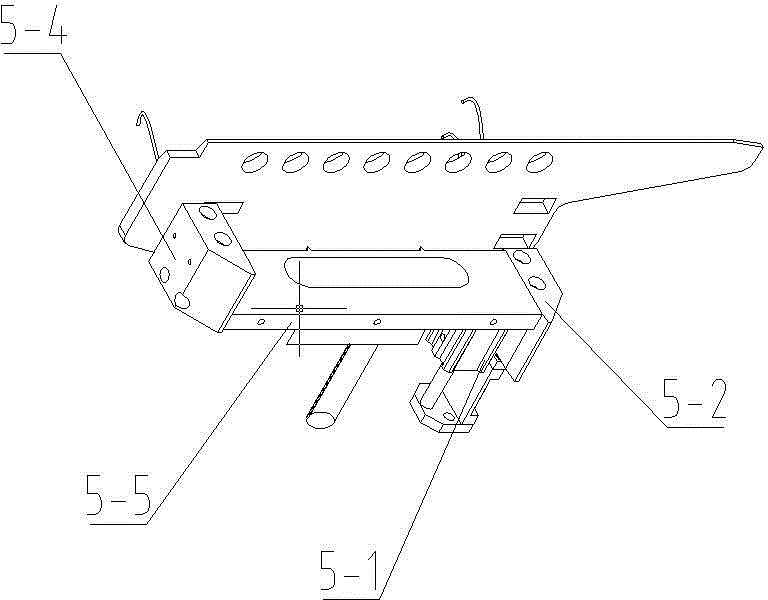

[0062] This embodiment is an improvement on the basis of Embodiment 1, and the difference from Embodiment 1 is that: Figure 4 As shown, the rodless cylinder of this embodiment is arranged along one side of the U-shaped conveying passage for tobacco rods of the carton transparent paper packaging machine, and the tobacco pushing plate can reciprocate in the U-shaped conveying passage for tobacco rods. The direction of the supplementary smoke inlet strip in this embodiment is the direction of the arrow.

Embodiment 3

[0064] The difference between the automatic cigarette filling system of the GD cigarette stick transparent paper packaging machine in this embodiment and the first embodiment is that the power switching device is omitted in this embodiment, and the original power output shaft connected to the carton packaging machine is connected to the The coupling between the input shafts of the drive carton transparent paper packaging machine is disconnected, and the power source is directly used to drive the carton transparent paper packaging machine.

[0065] The working process of the automatic cigarette filling system of the GD tobacco stick transparent paper packaging machine in this embodiment is basically the same as that of the first embodiment, except for the process of power switching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com