Stripping treatment method for cotton-polyester blended fabric

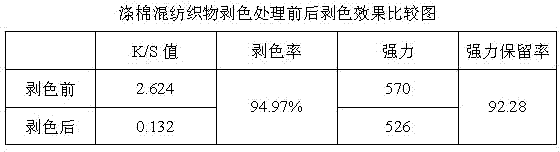

A technology of polyester-cotton blending and processing methods, which is applied in fiber processing, textiles, papermaking, plant fibers, etc., can solve problems such as difficult color stripping, deviation of analysis results, difficult to strip colors, etc., and achieve stable chemical, physical and mechanical properties. The data is detailed and accurate, and the stripping effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

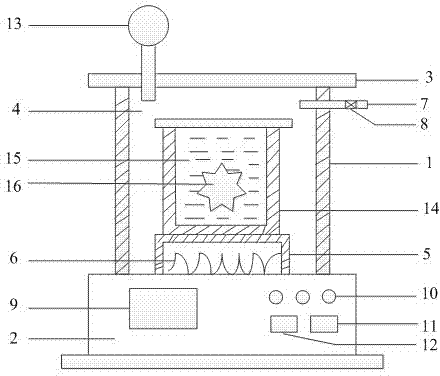

[0062] The present invention will be further described below in conjunction with accompanying drawing:

[0063] figure 1 Shown is the state diagram of the decolorization and dispersion treatment of polyester-cotton blended fabrics. The positions of each part must be correct and the operations should be performed in sequence.

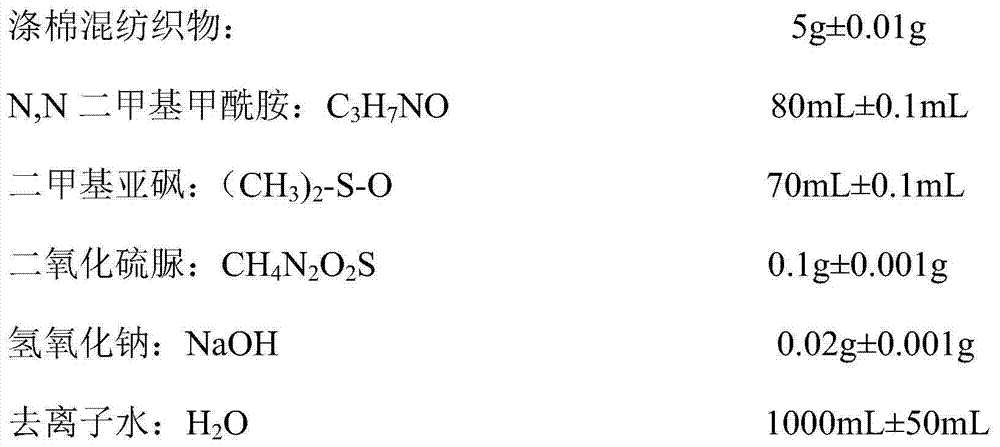

[0064] The amount of chemical substances used in the decolorization treatment of polyester-cotton blended fabrics is determined according to a preset range, with grams and milliliters as measurement units.

[0065] The stripping and dispersing treatment of polyester-cotton blended fabric is carried out in the dyeing test machine under the conditions of heating, pressurization and heat preservation;

[0066]The dyeing tester is vertical. The lower part of the dyeing tester 1 is the machine base 2, the upper part is the machine cover 3, and the inside is the machine chamber 4. The upper right wall of the dyeing tester is provided with an air outlet pipe 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com