Intensive multifunctional fully variable valve actuation system for 6-cylinder internal combustion engine

A drive system, internal combustion engine technology, applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of complex structure of the two-position five-way valve, complicated pressure difference changes, limiting performance improvement, etc., to improve idle speed and Performance in low and medium conditions, improved fuel consumption and emissions, and the effect of expanding application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention is illustrated by taking the system applied to the 1-5-3-6-2-4 type naturally aspirated internal combustion engine that adopts the intake as the row-the row as the advance braking mode as an example. The two-position two-way valve is used as the Take a normally closed valve as an example.

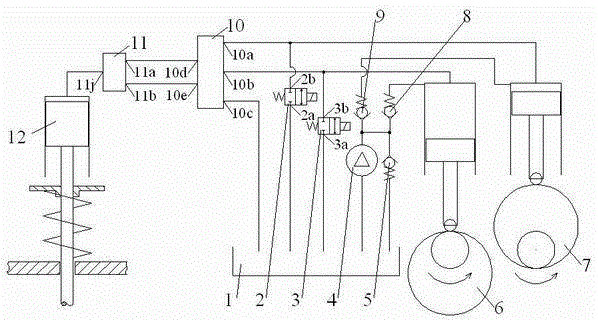

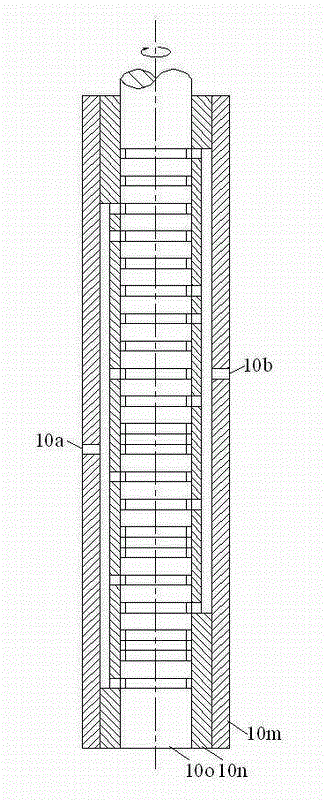

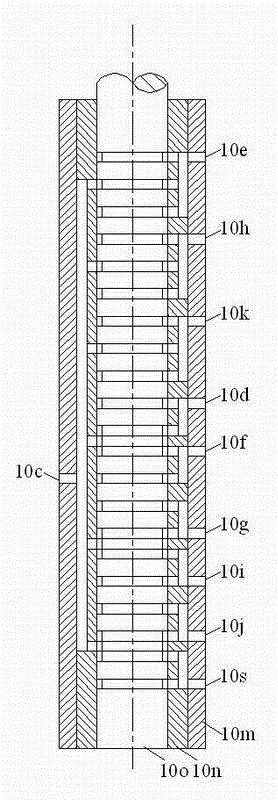

[0045] figure 1 A schematic diagram of an intensive multi-functional continuously variable valve drive system for a 6-cylinder internal combustion engine with a single valve is shown. Due to the design characteristics of this system, the operation of the valve driver 12 is determined by the movement rules of the first oil feeder 6, the second oil feeder 7 and the cycle selector 10, as well as the mode converter 11, the first two-position two-way valve 3 and the first 2 The working state of the two-position three-way valve 2 is jointly determined. According to the working state of the mode converter 11, the working process of the valve driver 12 can be divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com