Multilayered homogeneous crucible and installation method thereof

An installation method and crucible technology, which are applied to crucibles, crucible furnaces, furnaces, etc., can solve the problems of short service life of crucibles, unfavorable industrial production, and inability to meet requirements, and achieve the advantages of short installation period, simple and clear installation process, and improved use effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

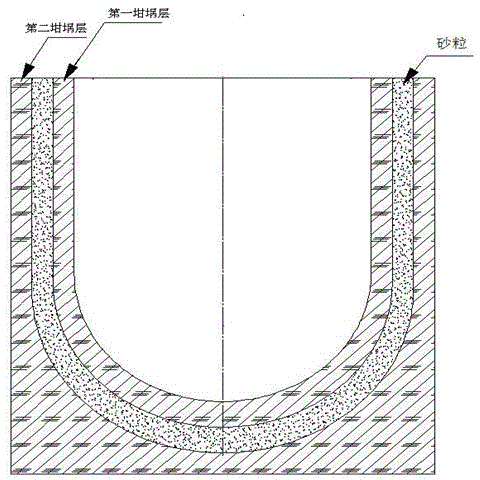

[0030] Such as figure 1 The scheme shown is a crucible with two crucible layers, two crucible layers, the inside is the first crucible layer, the outer layer is the second crucible layer gap filled with fine sand of the same material, the first crucible layer and the first crucible layer The materials are the same, and are also the same as those of the sand grains. The thickness of the first crucible layer is the same as that of the first crucible layer, and the geometric dimensions increase sequentially from the inside to the outside.

[0031] It is of course possible that the present invention can have three, four or more crucible layers depending on the specific circumstances.

[0032] The installation method of the homogeneous multilayer crucible comprises the following steps:

[0033] (1) Select a crucible of appropriate size and thickness as the first crucible layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com