Building type multi-layer mini-type dragon kiln

A building-type, miniature technology, applied in the direction of furnace type, furnace, lighting and heating equipment, etc., can solve the problems of large floor area, heavy labor intensity, heavy pollution, etc., achieve small floor space, wide applicability, convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

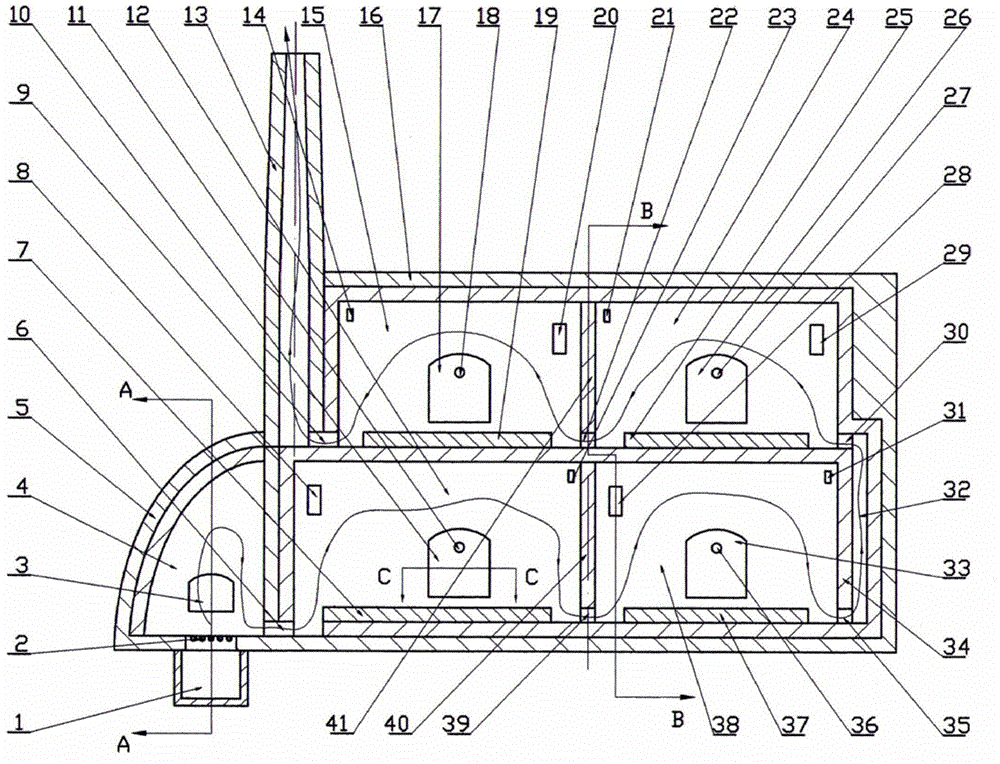

[0031] This embodiment is a two-story four-chamber miniature dragon kiln, including a furnace room, four kiln chambers and a chimney 13 (see appendix 13). Figure 1-4 shown).

[0032] The furnace room is composed of furnace table bubble 5, furnace door 3, furnace chamber 4, furnace bridge 2 and ash settling tank 1; furnace table bubble 5 is an arched cavity, the inner cavity is furnace chamber 4, and furnace door 3 is installed on the furnace table. The end face of the bubble 5, the furnace bridge 2 is installed below the furnace 4; the ash sink 1 is arranged under the furnace bridge 2, and the exposed end of the ash sink 1 is also installed with an air inlet pipe, on the air inlet pipe The air volume control valve 42 is attached.

[0033] The four kiln chambers are the first kiln chamber 12 on the first floor, the second kiln chamber 38 on the first floor, the first kiln chamber 24 on the second floor and the second kiln chamber 15 on the second floor. On the side of each k...

Embodiment 2

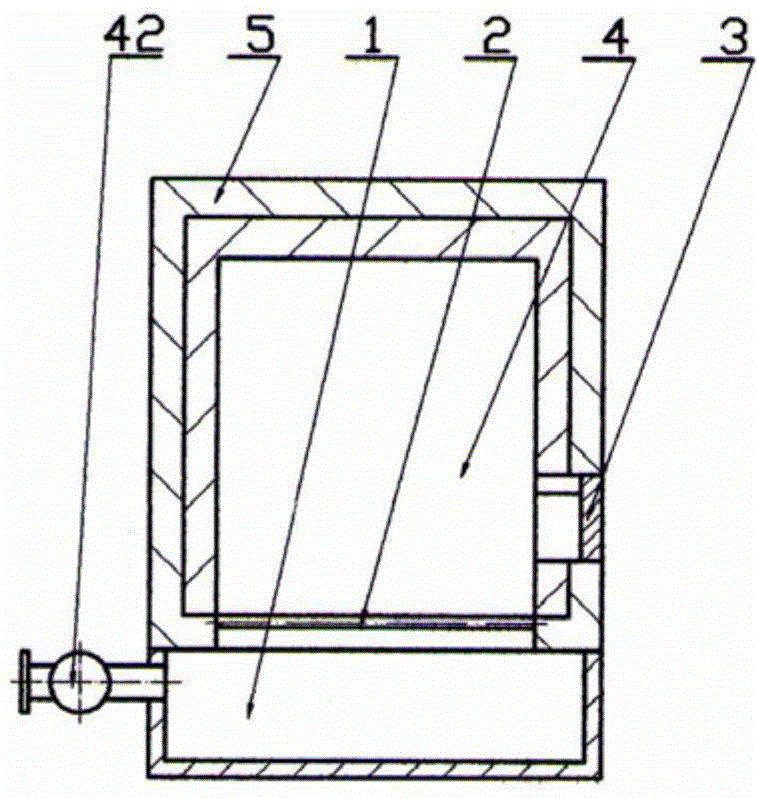

[0042] This embodiment is a miniature dragon kiln with two floors and two rooms, including a furnace room, two kiln rooms and a chimney 13 (see attached Figure 5 shown), which is a variation of the first embodiment, which is improved on the basis of the first embodiment, that is, a kiln chamber is set up on the upper and lower layers, and the others are basically the same as those in the first embodiment.

Embodiment 3

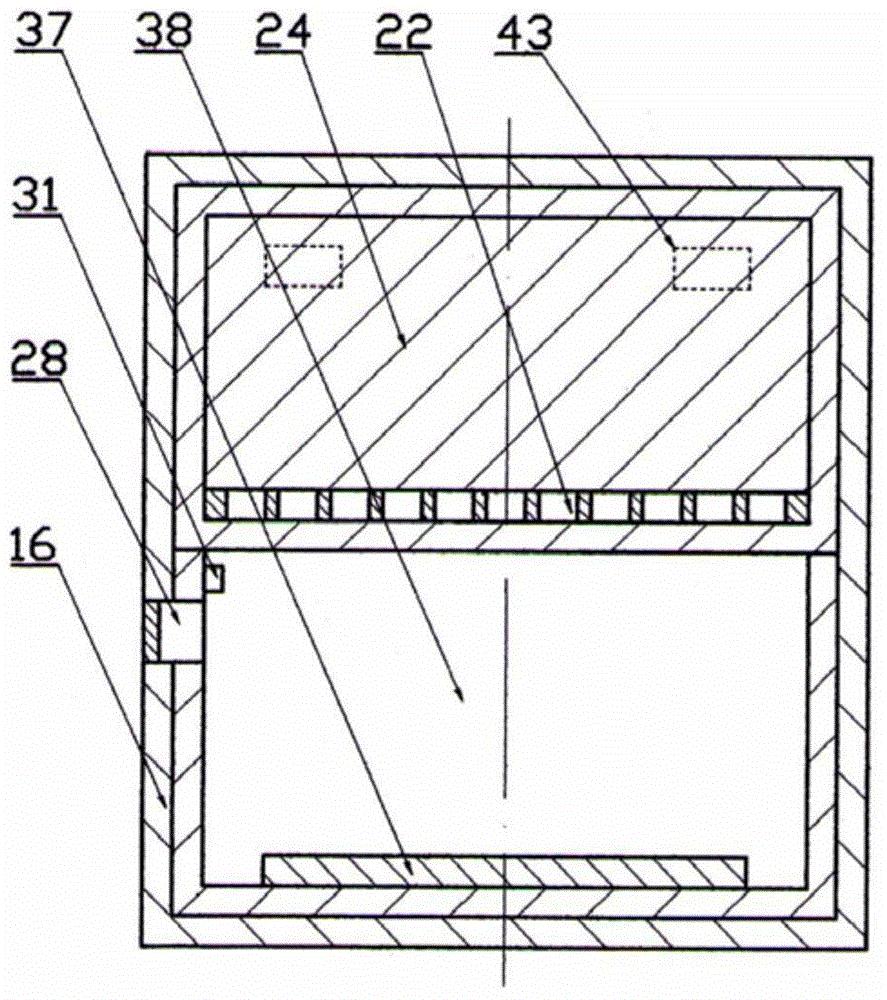

[0044] This embodiment is a two-story three-chamber miniature dragon kiln, including a furnace room, three kiln chambers and a chimney 13. It is a variation of the first embodiment, and is improved on the basis of the first embodiment or the second embodiment. There are two schemes. :

[0045] One is the upper and lower floors, with one kiln room on the upper level and two kiln rooms on the lower level (see attached). Image 6 shown), the others are basically the same as the first embodiment;

[0046] The second is the upper and lower floors, with two kiln chambers on the upper layer and one kiln chamber on the lower layer (see attached). Figure 7 shown), and others are basically the same as the first embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap