A measuring instrument and measuring method capable of adapting to the shell surface of a flywheel

A measurement method and flywheel housing technology, applied in the direction of measuring device, mechanical measuring device, mechanical roughness/irregularity measurement, etc., can solve problems such as low practicability, operator's subjective judgment error, large detection error, etc., to achieve Improved detection efficiency, shortened measurement time, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

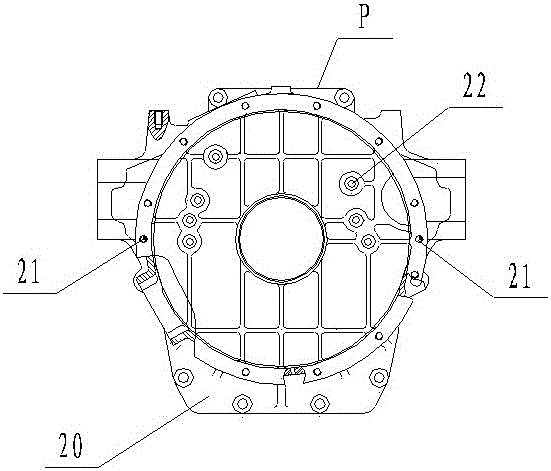

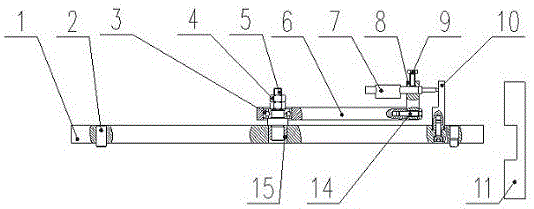

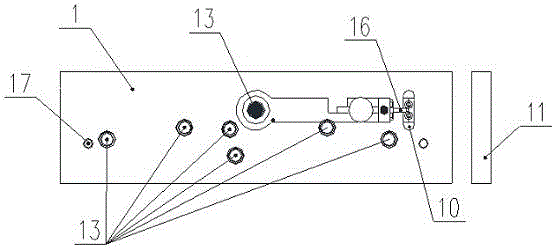

[0012] Embodiment 1: to detect attached figure 1 Take the flywheel housing shown in as an example, refer to the attached figure 2 , 3 , 4. A measuring tool for a flywheel housing, which includes a measuring tool base 1, a rotating shaft 5, a moving plate 6, a fixed plate 8, and a gauge block 11; positioning holes 17 are respectively opened on the two ends of the measuring tool base 1, and the positioning holes 17 Corresponding to the pin holes 21 on the flywheel housing 20 respectively; positioning pins 2 and rhombic pins 13 are respectively provided in the positioning holes 17, and the measuring tool base 1 is positioned on the flywheel housing 20; the measuring tool base 1 is also provided with A plurality of measuring holes 18; and a plurality of measuring holes 18 correspond to different shell surfaces of the flywheel housing; the measuring holes 18 are provided with positioning drill bushings 15; the upper part of the rotating shaft 5 is plugged with the positioning dr...

Embodiment 2

[0013] Embodiment 2: on the basis of embodiment 1, a kind of measuring method that can adapt to the measuring instrument with many flywheel shell surfaces, (1) utilize the flywheel shell concave surface and the positioning hole of the concave surface to locate the specific amount; (2) drill 7 on the clamp body The hole is tightly matched with the drill bushing, and the equidistant table block is installed at the same time; (3) the rotating shaft is matched with each drill bushing with a small gap; it is tightly matched with the inner ring of the bearing, and the bearing and the rotating shaft are paralleled by two nuts at the same time. tight to ensure that the mobile plate can rotate and move freely; (4) one end of the mobile plate is tightly fitted with the outer ring of the bearing to prevent the mobile plate from loosening; the other end is tightly connected to the fixed block of the dial indicator; (5) Install the dial indicator into the through hole of the dial indicator ...

Embodiment 3

[0021] Embodiment 3: on the basis of embodiment 1. In order to measure the machined hole 22 of the flywheel housing 20 more conveniently and accurately, the measuring hole 18 on the base 1 can also be processed to be coaxial with the machined hole 22 on the flywheel housing 20, so that it can be more conveniently measured The distance between each processing hole and the processing surface is shown; the dial indicator 7 can also be replaced by a dial indicator or a vernier caliper, and the sleeve of the dial indicator is inserted and fastened in the through hole of the fixed plate 8 to detect The head protrudes outwards, and the chi body of the vernier caliper is inserted and fastened in the through hole of the fixed plate 8, and the depth gauge protrudes outwards.

[0022] The measuring instrument of the present invention can realize the measurement of each processing surface of the flywheel housing at 360 degrees, and can conveniently and quickly measure the distance, symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com