Device for detecting safety belt assembly in front row of car

A detection device and seat belt technology, which is applied in the direction of measuring device, mechanical measuring device, vehicle testing, etc., can solve the problems of seat belt webbing shrinkage failure stuck, seat belt assembly mounting hole offset, etc., to avoid installation difficulties Questions, Check Consistency, Guaranteed Precision Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

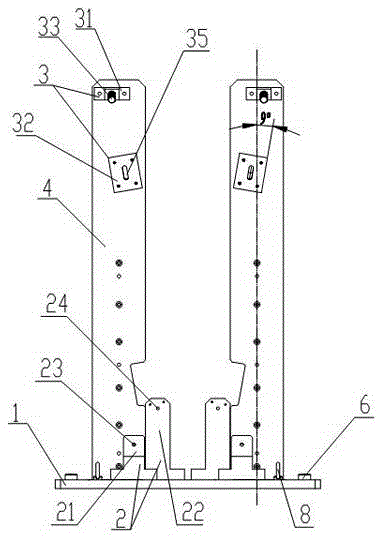

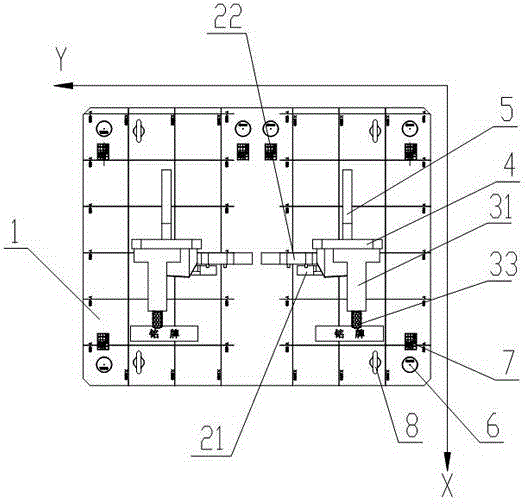

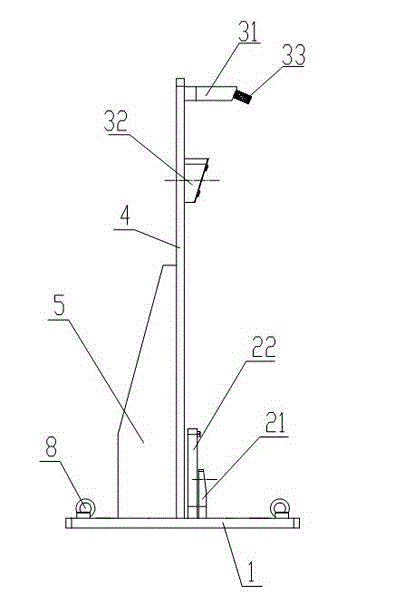

[0028] exist figure 1 In the shown embodiment, a detection device for the front seat belt assembly of a car includes a base plate 1, a positioning plate 2, a positioning block 3 and a support plate 4, the base plate 1 is a square plate, and two sets of Positioning plate 2, positioning block 3 and supporting plate 4. Four eyebolts 8 are also arranged symmetrically on the bottom plate 1 (see figure 2 ).

[0029] The base plate 1 is provided with reference coordinates in the X and Y directions, and the reference coordinates in the X and Y directions are respectively set along the four corners and a bottom edge of the base plate. The reference coordinates in the X and Y directions are three reference inserts 6 and three The spare reference insert 6 is provided with a coordinate plate 7 on the bottom plate 1 corresponding to the position of the reference insert 6 . The supporting plate 4 and the positioning plate 2 are respectively arranged perpendicular to the base plate 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com