Dispensing processing method for sealing rubber strip of waterproof type-c connector

A technology of sealing strips and processing methods, applied in the direction of coating, etc., can solve the problems of soaring defective product rate, difficult installation, material waste, etc., and achieve high production efficiency, avoid difficult installation, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention will be further explained below in conjunction with the drawings:

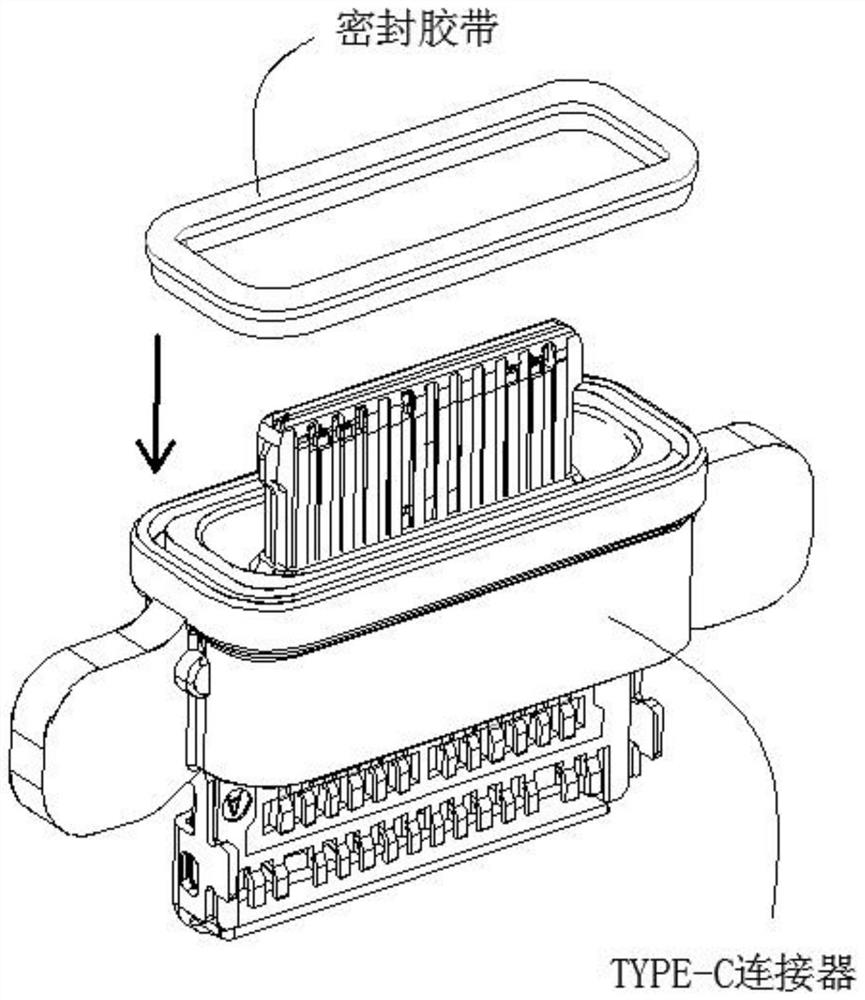

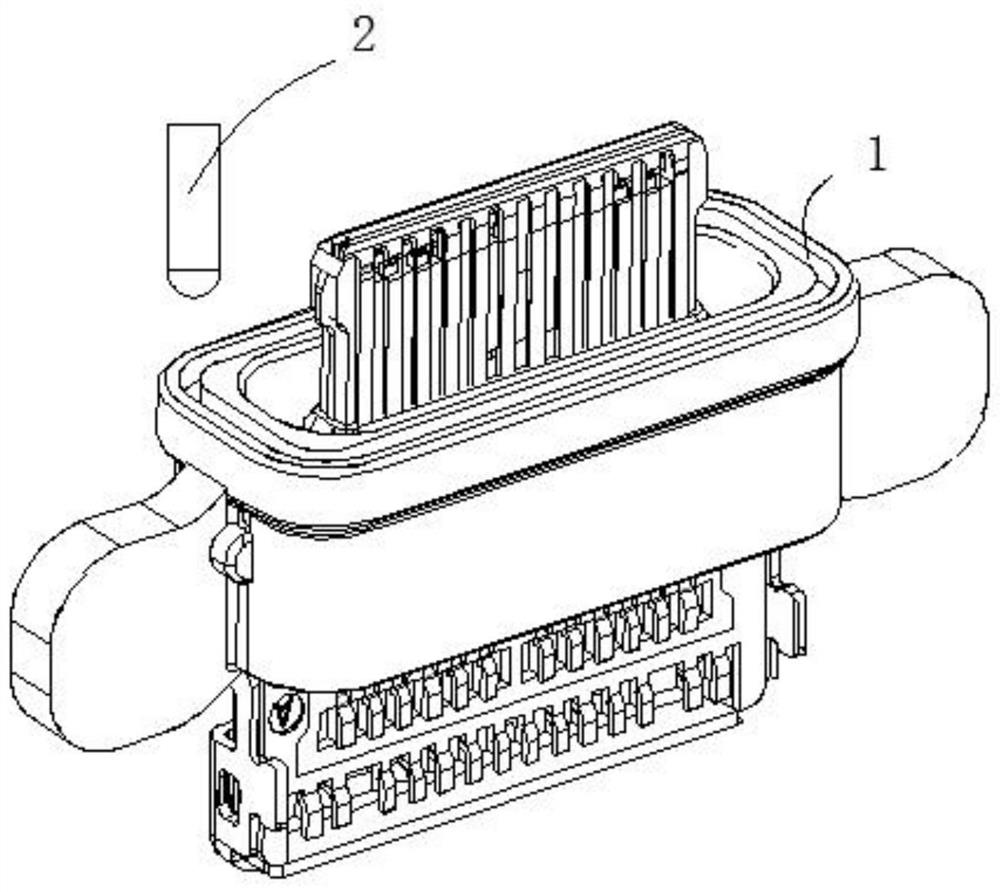

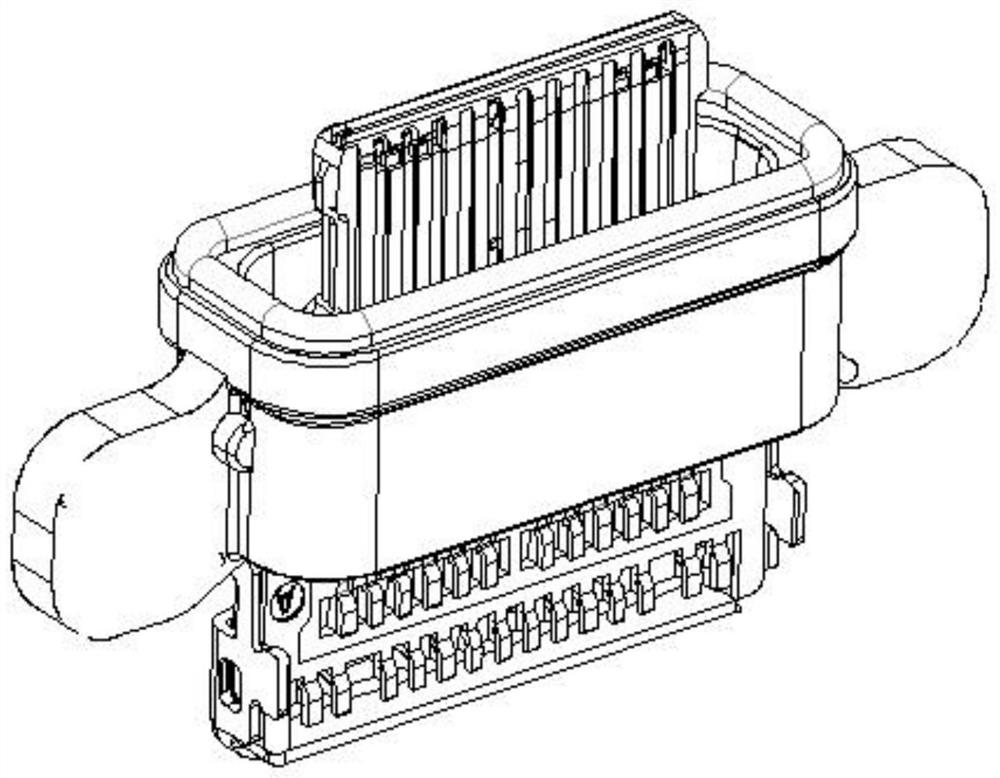

[0021]referencefigure 2 ,Figure 4, A dispensing processing method for a sealing strip of a waterproof typc-c connector, wherein the surface of the female seat has a closed-shaped glue tank 1 connected end to end, and a sealing strip installed on the glue tank 1, so The sealant strip is divided into an upper part and a lower part. The lower part is used to be inserted into the glue tank 1 and fits closely with the glue tank 1, and the upper part is exposed outside the glue tank 1 and is used for connecting with the smart device The shells are in close contact to form a waterproof structure, and the processing method of the sealing rubber strip includes the following steps:

[0022]Step A: Preparation of the dispenser: Pour the UV semi-cured glue into the jet dispenser, and adjust the minimum air pressure and optimum temperature.

[0023]In this embodiment, the UV semi-curing glue adopts a one-compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com