Air pump braking resilience device with ABS function of wheel

A technology of air pumps and wheels, which is applied to vehicle components, transportation and packaging, control valves and air release valves, etc., which can solve the problems of heavy and complex mechanisms and potential safety hazards, and achieve the effects of convenient installation, cost reduction, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

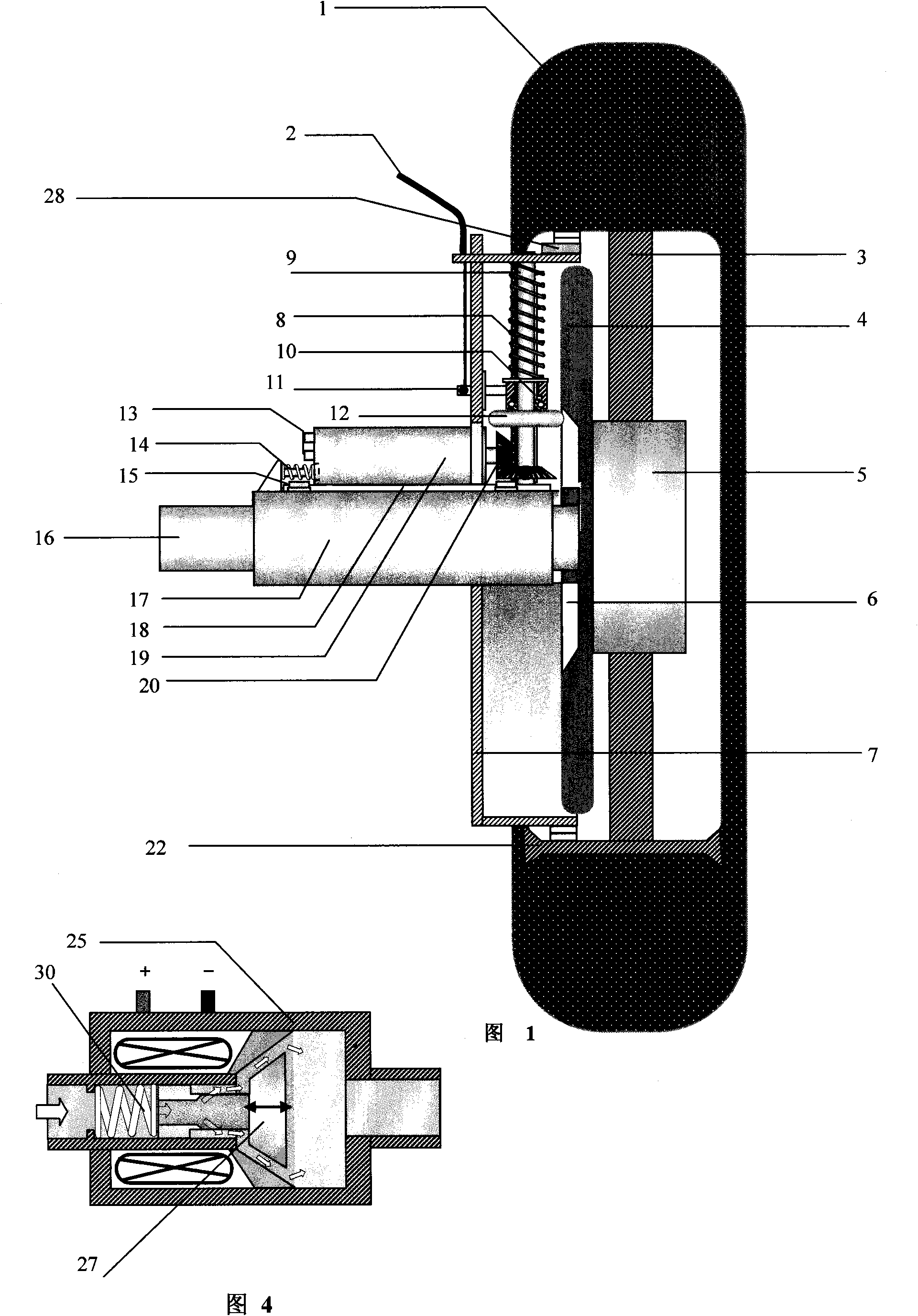

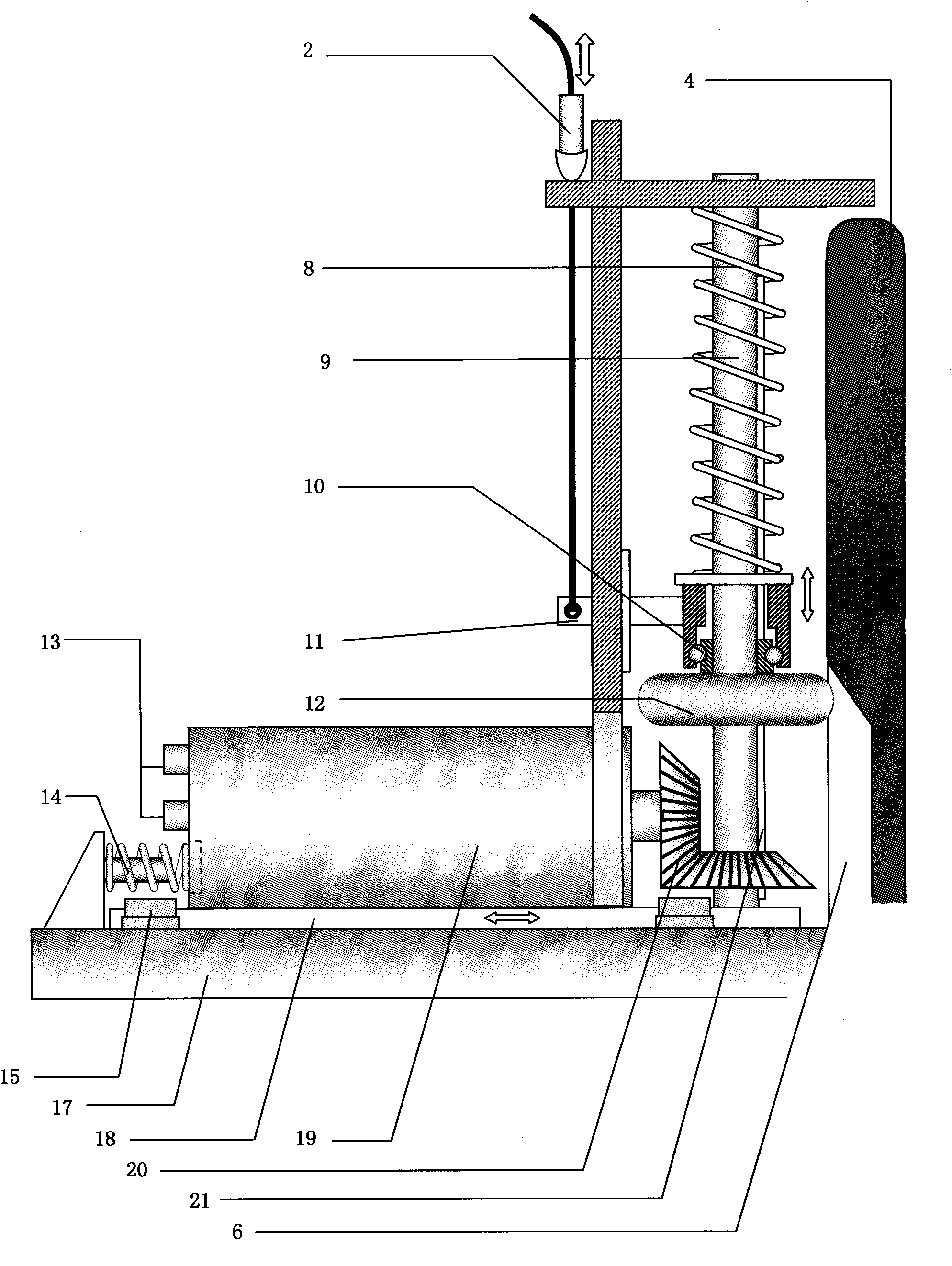

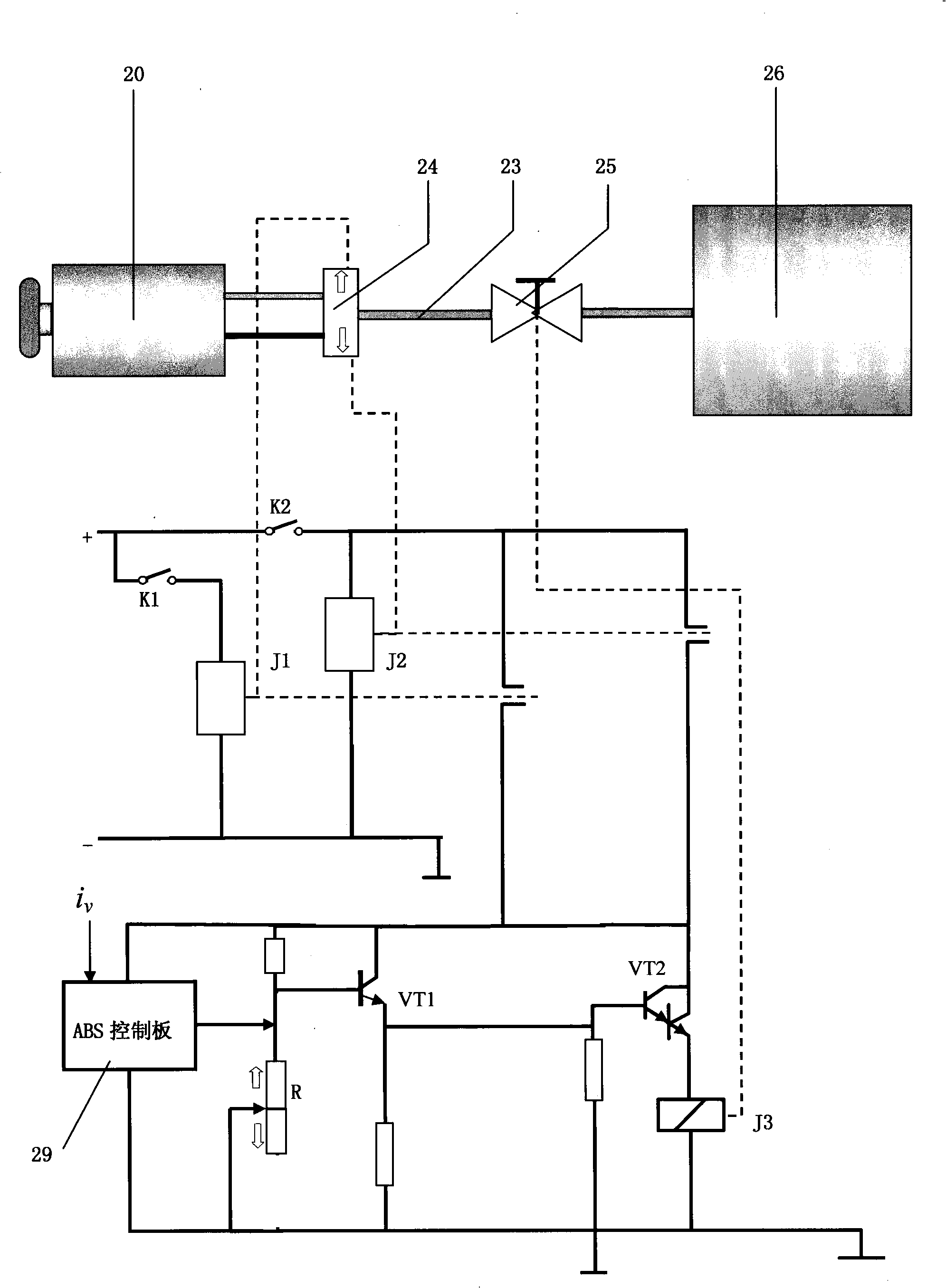

[0016] Attached below Figure 1~4 And embodiment further illustrate the present invention.

[0017] Sliding plate 18 is installed on the shell of the axle bearing 17 of axle shaft 16, and this brake air pump 19 is fixed on the sliding plate 18 again. The base of air pump 19 is slide plate 18, and slide plate is fixed by slide pressing piece 15. Such a structure allows the air pump 19 to move freely back and forth, and the purpose is to make the pressure spring 14 push the air pump 19 forward when braking, so that the brake roller 12 is pressed tightly against the surface of the brake disc 4 without slipping.

[0018] When not working, the brake roller 12 is in the groove 6 of the brake disc and does not come into contact with the brake disc. And when stepping on the brake pedal in the brake, the control line 2 pulls the pull rod 11 to move, and the brake roller 12 moves gently on the brake disc 4 by the slope of the brake disc groove 6, and the air pump 19 starts working. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com