A method and device for rapid and uniform sensitization of photoanodes of dye-sensitized solar cells

A technology for solar cells and dye sensitization, which is applied in the field of rapid and uniform adsorption of dye sensitizers on photoanodes of dye-sensitized solar cells, can solve the problems of uneven adsorption of nano-semiconductor films, and achieve the convenience of large-scale production, ensure uniformity, Solve the effect of long adsorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

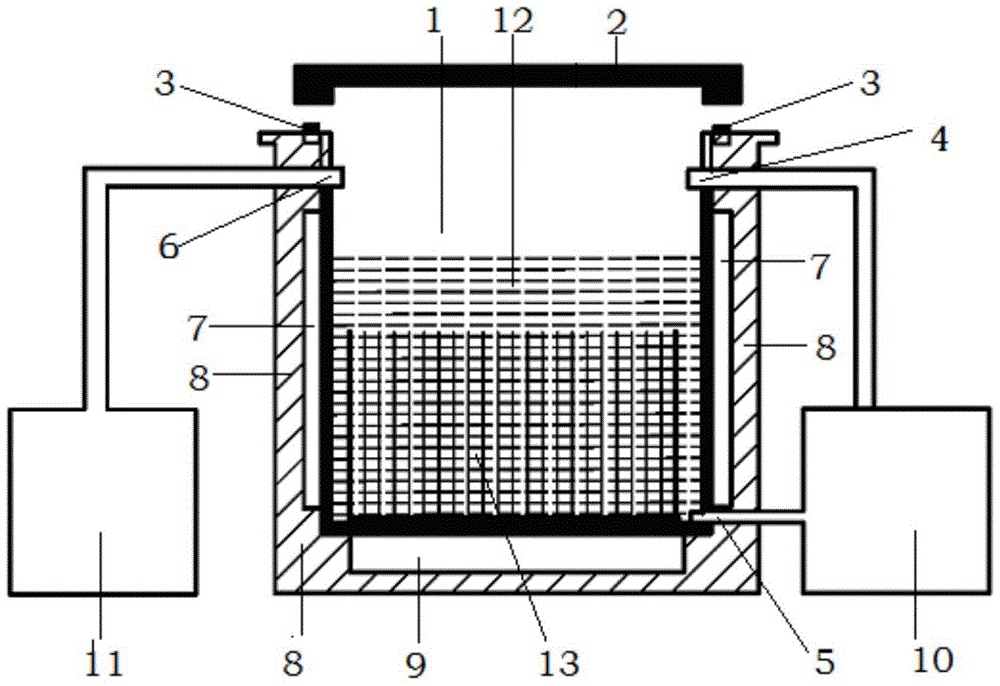

[0033] see figure 1 , turn on the heating device of the heating chamber 7 of the dye soaking machine, keep the dye solution in the soaking chamber at a temperature of 40° C., put the storage rack equipped with the photoanode 13 into the soaking chamber 1, the dye solution 12 completely covers the photoanode 13, cover the Sealing cover 2. Open the compressed air valve of the pressurizing device 11 to keep the 0.1 MPa atmospheric pressure in the soaking chamber 1. Turn on the ultrasonic device 9, and maintain the ultrasonic power at 200 W. Turn on the dye solution circulation device 10, and the flow rate of the dye solution is 10 L / min. After maintaining the above operation for half an hour, close the dye solution circulation device 10, close the ultrasonic device 9 and the compressed air valve, open the sealing cover 2, take out the storage rack, and put the next batch of storage racks into the soaking chamber 1 for photoanodic dye sensitization agent adsorption operation. ...

Embodiment 2

[0036] see figure 1 , put the storage rack equipped with the photoanode 13 into the soaking chamber 1 at normal temperature, the dye solution 12 completely covers the photoanode 13, and cover the sealing cover 2. Open the compressed air valve of the pressurizing device 11 to keep the 0.1 MPa atmospheric pressure in the soaking chamber 1. After maintaining the above operation for half an hour, close the compressed air valve, open the sealing cover 2, and take out the storage rack.

[0037] The desorption test was carried out on 25 photoanodes adsorbed with dye sensitizers, and the lowest dye adsorption amount was 0.12×10 -8 mol μm -1 cm -2 , up to 0.2×10 -8 mol μm -1 cm -2 .

Embodiment 3

[0039] see figure 1 , turn on the heating device of the heating chamber 7 of the dye soaking machine, keep the dye solution in the soaking chamber 1 at a temperature of 40°C, put the storage rack equipped with the photoanode 13 into the soaking chamber 1, and the dye solution 12 completely covers the photoanode 13, Close the sealing cap 2. Open the compressed air valve of the pressurizing device 11 to keep the 0.1 MPa atmospheric pressure in the soaking chamber. After maintaining the above operation for half an hour, turn off the heating device and the compressed air valve, open the sealing cover 2, and take out the storage rack.

[0040] The desorption test was carried out on 25 photoanodes adsorbed with dye sensitizers, and the lowest dye adsorption amount was 0.32×10 -8 mol μm -1 cm -2 , up to 0.46×10 -8 mol μm -1 cm -2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com