Anti-skid device for tire

A technology for anti-skid devices and tires, applied in the directions of anti-skid devices, tire parts, wheels, etc., can solve the problems of poor fuel economy, difficult installation of metal chains, and high cost of studless tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] "summary"

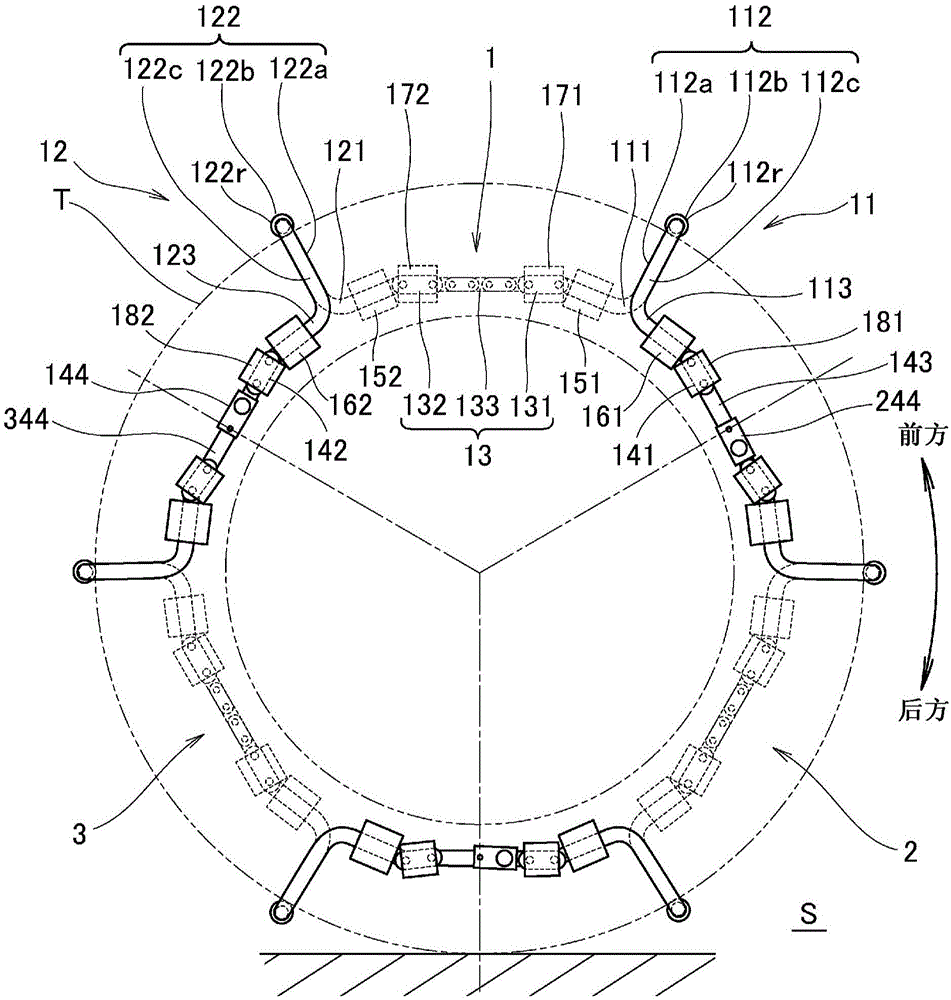

[0037] figure 1 A case where a tire anti-skid device S (abbreviated as "anti-skid device S") as an embodiment of the present invention is attached to a tire T for a large automobile is shown in FIG. The anti-slip device S is composed of three unit units 1 , 2 , and 3 . Each of the unit units 1, 2, and 3 is in the same manner. On the decorative surface side of the wheel hub (not shown), that is, the outer side of the tire T ( figure 1side of the paper) are connected in a detachable manner. Hereinafter, as one of the unit cells 1, refer to the enlarged view of the unit cell 1. figure 2 Describe in detail.

[0038] "Unit Unit"

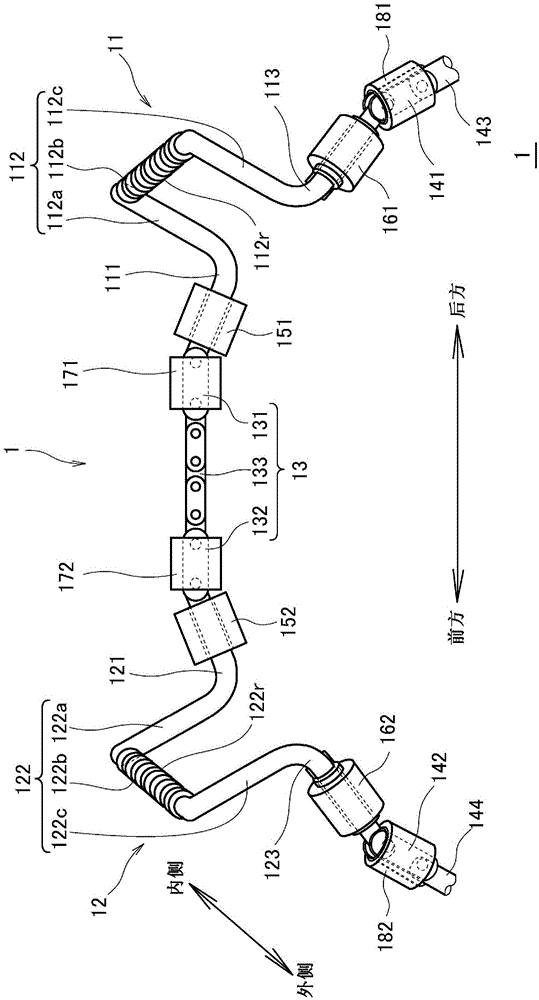

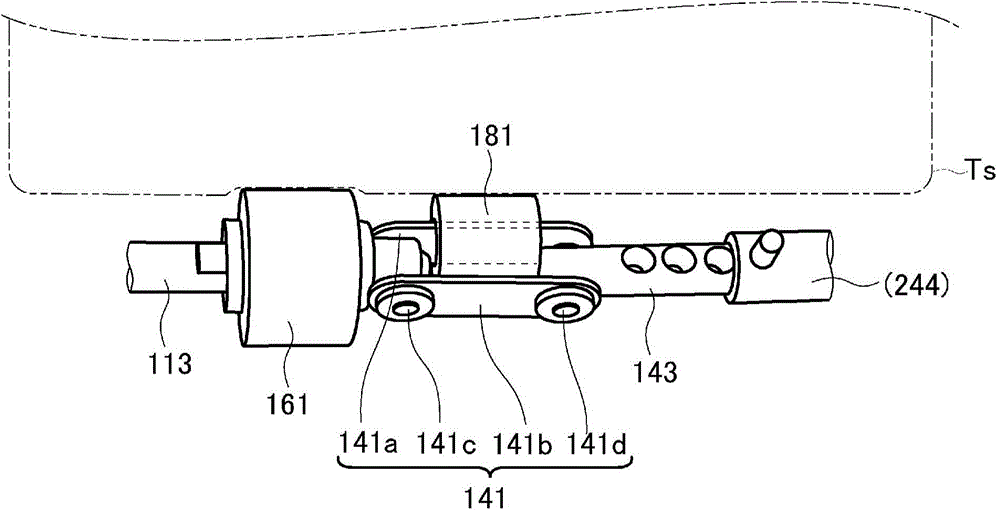

[0039] The unit unit 1 is composed of a first main body 11, a second main body 12, an inner connecting piece 13 (131, 132, 133), an outer connecting piece 14 (141, 142, 143, 144), an inner abutting member 15 (151, 152) , the outer contact member 16 (161, 162), the inner contact member 17 (171, 172), and the outer contact member 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com