Laser height measuring device and component mounting machine

A measuring device and laser technology, which is applied to measuring devices, optical devices, electrical components, etc., can solve the problems such as the reduction of height measurement accuracy, the influence of laser height sensor height measurement accuracy, and the change of reflectivity, so as to ensure the control accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

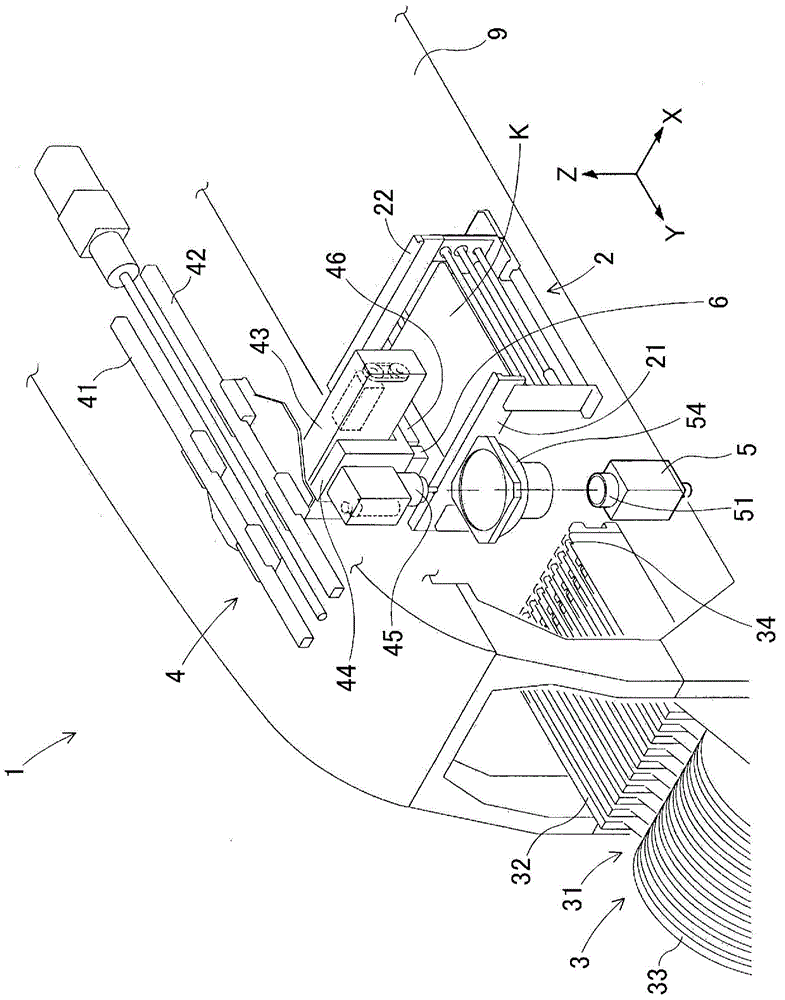

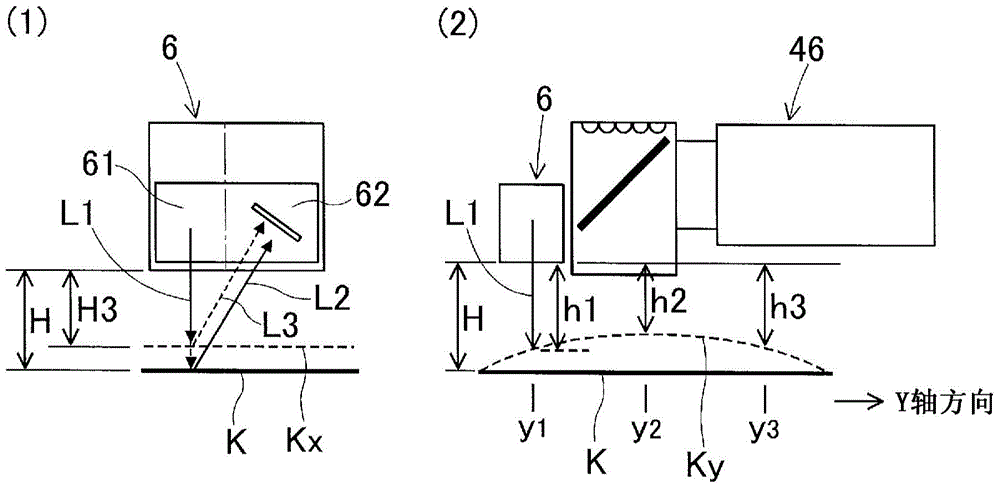

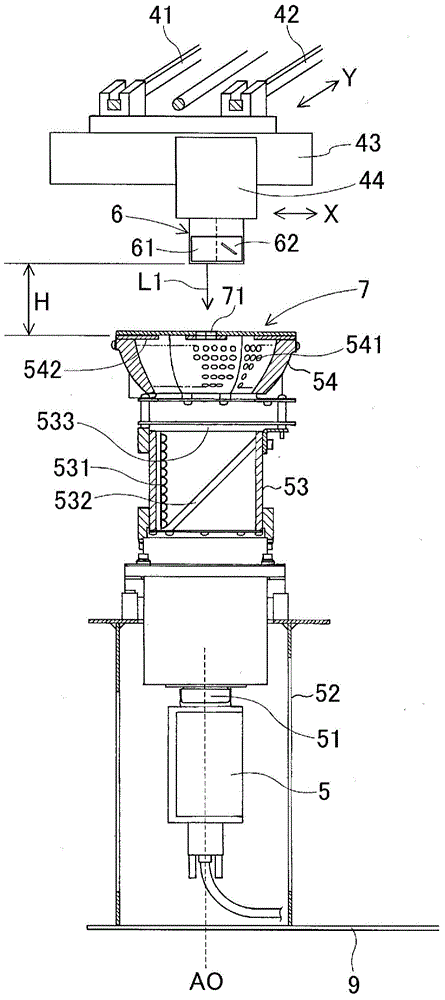

[0032] reference Figure 1~Figure 8 The component mounting machine according to the embodiment of the present invention will be described. figure 1 It is a perspective view explaining the component mounting machine 1 of an embodiment. The laser height measuring device of the present invention is incorporated in the component mounting machine 1 of the embodiment. The component mounting machine 1 is configured as follows: a board transfer device 2, a component supply device 3, a component transfer device 4, and a component camera 5 are assembled on a base 9, and a laser height sensor is mounted on the mounting head 44 of the component transfer device 4 6. Each device 2-6 is controlled by a control computer not shown.

[0033] The substrate conveying device 2 is composed of first and second guide rails 21 and 22, a pair of conveyor belts, a fastening device, and the like. The first and second guide rails 21 and 22 are assembled on the base 9 so as to extend in the conveying direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com