Sand making method and sand making device

A sorting device and raw material technology, applied in grain processing and other directions, can solve the problems of polluting the environment, affecting the quality of machine-made sand, reducing the yield of machine-made sand, etc., and achieving the effect of reducing the amount of dust generated, reducing the amount of production, and increasing collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The following will refer to the attached figure 1 The present invention will be described in detail in combination with examples.

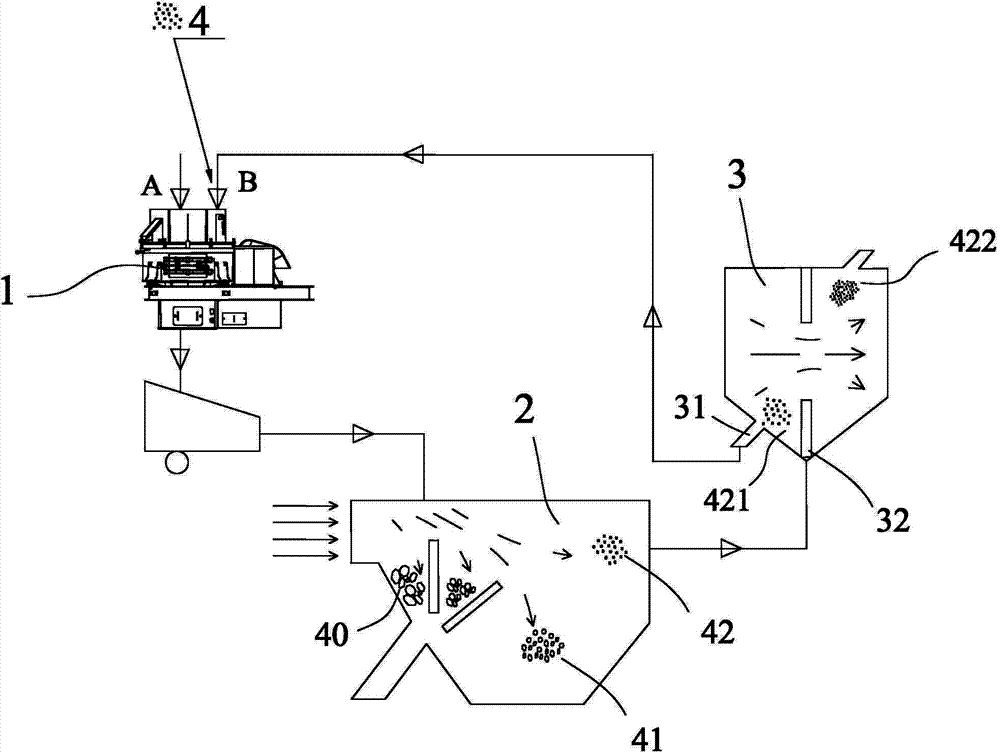

[0021] The specific embodiment of the present invention provides a kind of sand making method, such as figure 1 As shown, the sand making method includes a feeding process, preparing raw materials to be crushed and buffer materials 4, and sending them into the crusher 1; crushing process, after the raw materials and buffer materials 4 enter the crushing chamber of the crusher 1, they are crushed in the rotor Under high-speed operation, the crusher 1 crushes the raw materials to obtain a crushed raw material mixture; in the sorting process, the crushed raw material mixture obtained through crushing is screened to obtain particles with the required particle size. In the prior art,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com