Lithium iron phosphate power battery consistency matching screening method

A power battery, lithium iron phosphate technology, applied in the direction of measuring electricity, measuring electrical variables, measuring devices, etc., can solve the problems of consistency deviation, battery performance degradation, fire and explosion, etc., to achieve rapid consistency and achieve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

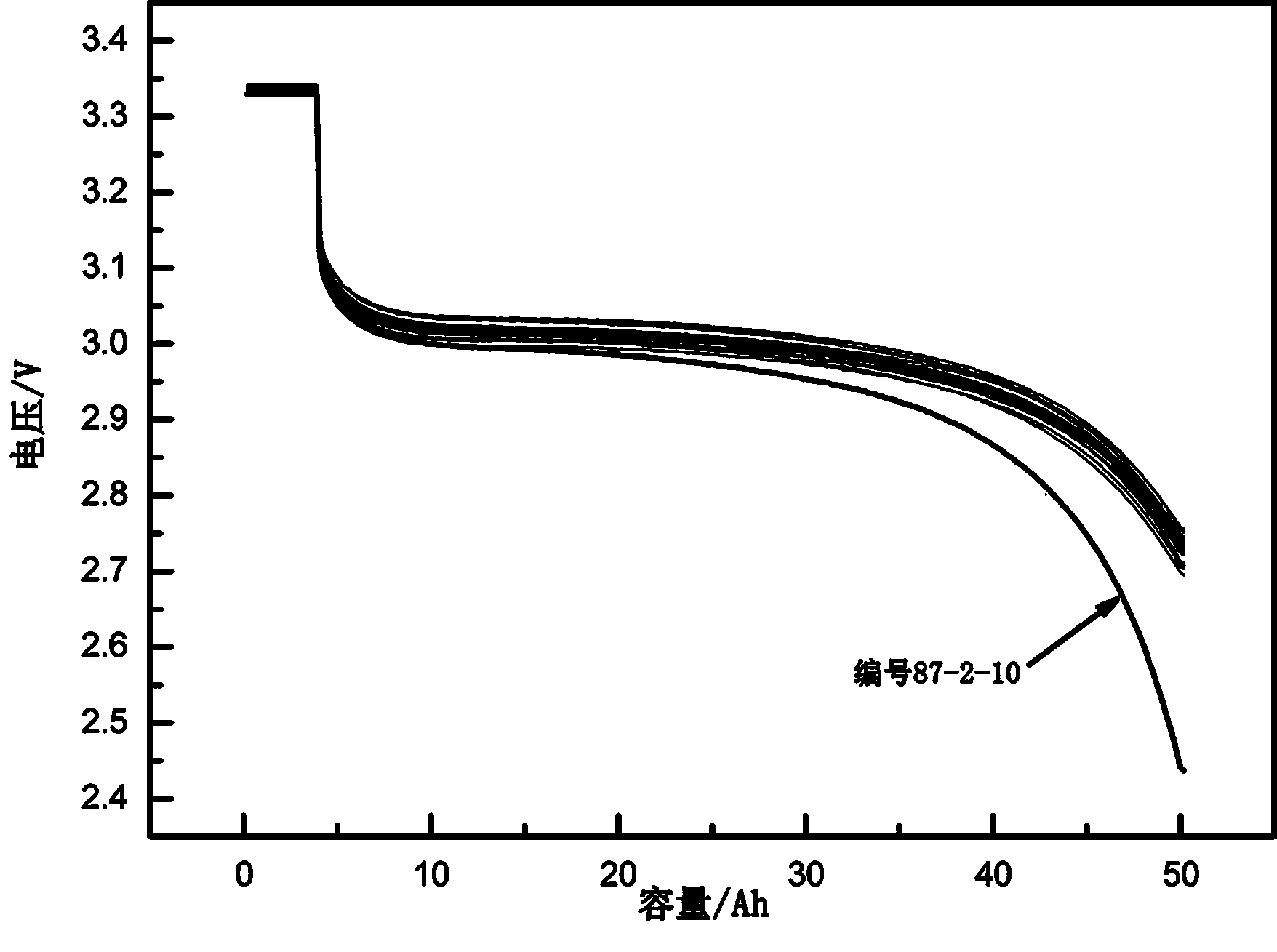

[0026] Use the lithium iron phosphate power battery with a battery capacity of 50Ah to carry out battery consistency matching screening, and follow the steps below:

[0027] (1) Screen lithium iron phosphate power batteries into groups, at least meeting the following conditions:

[0028] A. Check the battery composition and capacity data, and eliminate unqualified batteries with a capacity less than 50Ah;

[0029] B. When the battery is screened, the internal resistance difference between the individual cells of each battery group is ≤0.03mΩ, and the voltage difference is ≤20mV;

[0030] C. When screening batteries, the capacity of each platform of the battery must meet the following requirements, 3.2V platform capacity ≥ 30Ah, 3.1V platform capacity ≥ 40Ah, 2.9V platform capacity ≥ 47.5Ah;

[0031] D. When screening by platform, the capacity difference of each platform of the same group of batteries must meet the following requirements, 3.2V platform capacity difference ≤ 2A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com