Multi-module multi-directional high-frequency vibration thermoforming die

A high-frequency vibration, multi-module technology, applied in the direction of forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult adjustment of frequency and amplitude, limited output power, limited vibration direction, etc., to improve the friction state, reduce the Small flow stress, overcoming limited effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

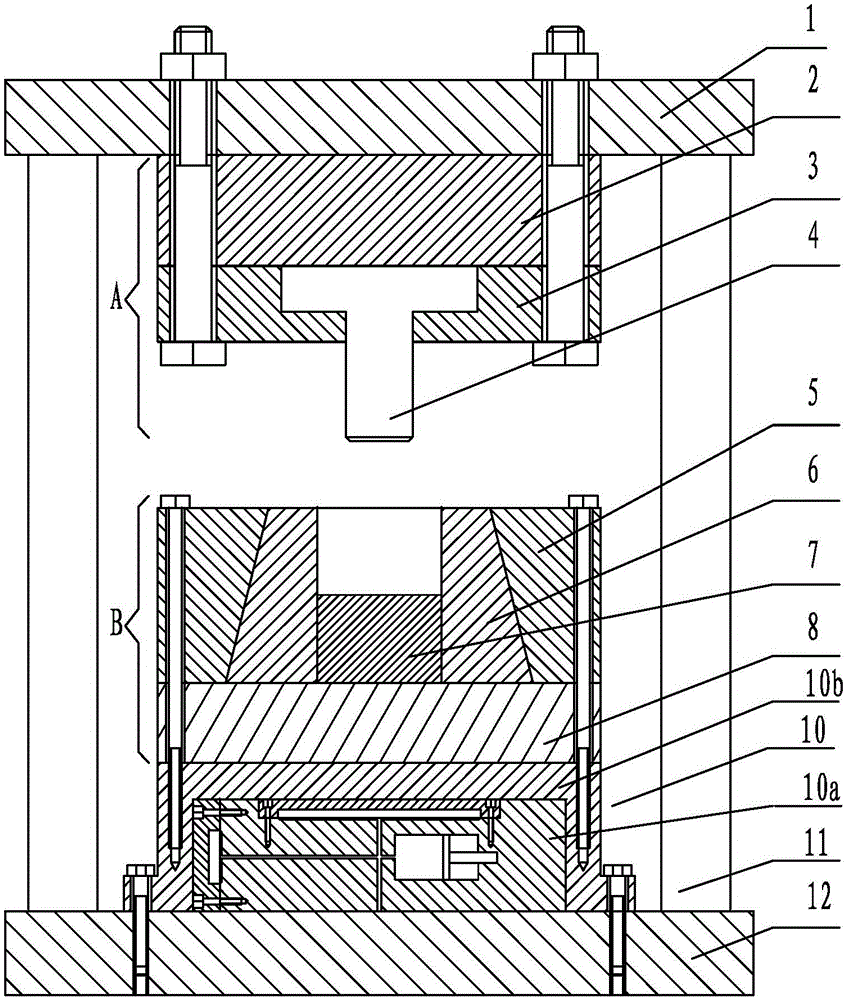

[0024] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 7 :

[0025] The multi-module multi-directional high-frequency vibration thermoforming mold includes the upper mold A, the upper mold A and the guide rod 11 for the relative movement of the upper and lower molds. The lower side of the lower mold B is provided with a hydraulic exciter 10.

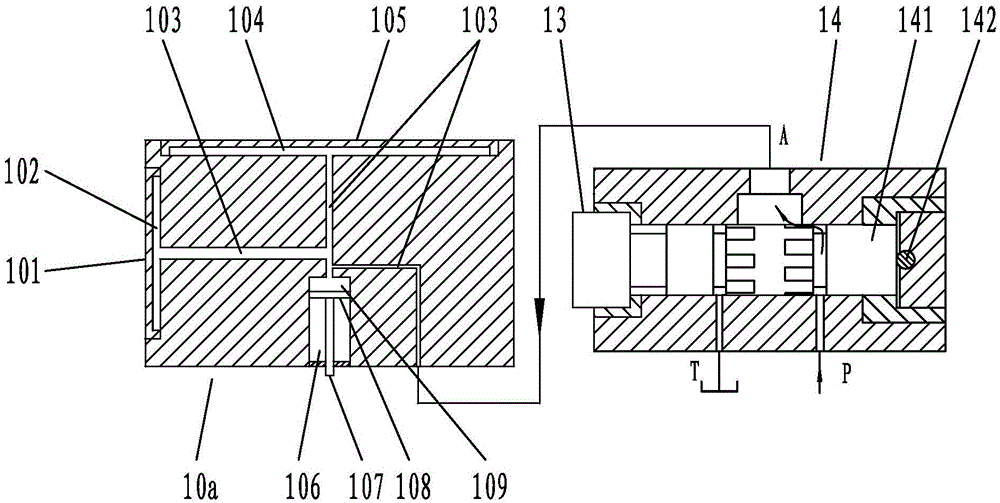

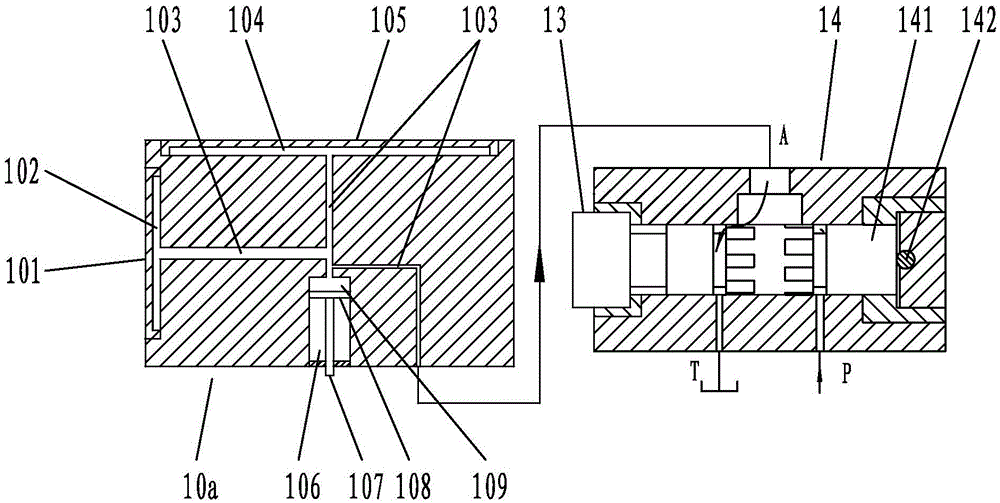

[0026] The specific structure of the above-mentioned hydraulic vibrator 10 is: an exciter 10a is provided in the outer ring 10b of the hydraulic exciter, and at least one horizontal plane and at least one vertical plane of the exciter 10a are respectively provided with more than one groove, The opening of each groove is provided with elastic end caps 101, 105 to form chatter chambers 102, 104, and all chatter chambers 102, 104 communicate with the vibration valve 14 driven by the servo motor 13 through the hydraulic pipeline 103, The oil i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com