Strip plate punching auxiliary feed device

A sheet metal stamping and auxiliary feeding technology, applied in the directions of feeding device, positioning device, storage device, etc., can solve the problems of large worktable area, poor sheet rigidity, long feeding distance, etc., and achieve good transmission quality and small sheet deformation. , The effect of supporting reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

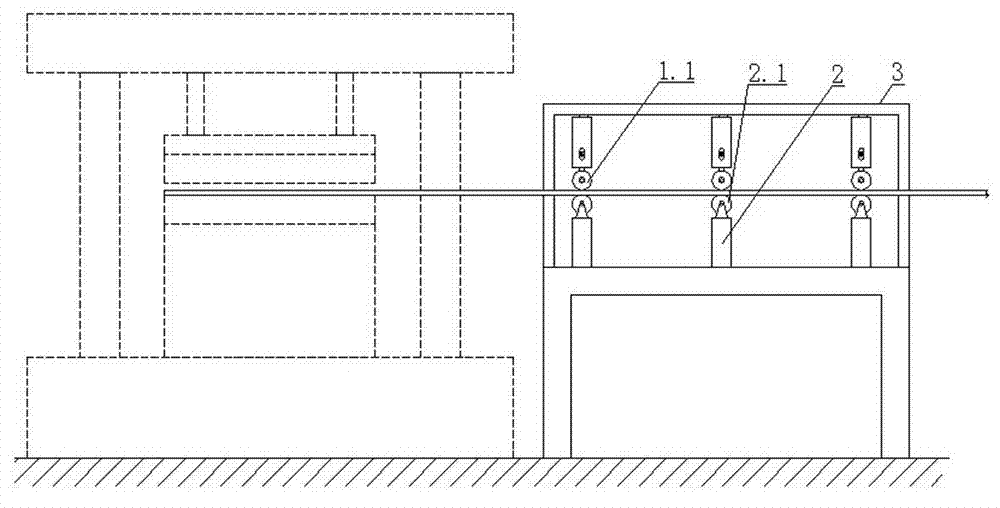

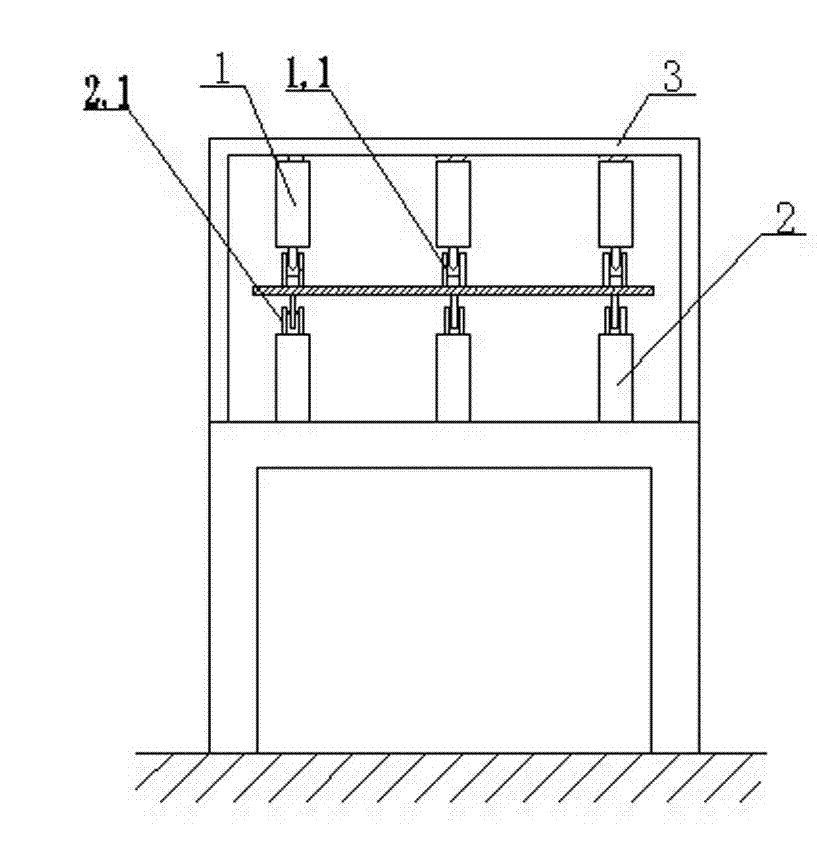

[0013] figure 1 The auxiliary feeding device for stamping strip-shaped sheet metal shown is placed between the 315T automatic punching machine table and the feeding mechanism, and it includes an upper roller seat 1, a lower roller seat 2 and a bracket 3. Bracket 3 is a basic component for pairing and installing upper roll base 1 and lower roll base 2. In this embodiment, bracket 3 is a double-layer rectangular frame. Since the working table of the 315T automatic punch press and the feeding mechanism are separated by 1500mm, the upper surface of the bottom frame Along the feeding direction, three sets of lower roller seats 2 of the same height are alternated. The roller shaft 2.1 of the lower roller seat 2 is a positioning and rotating structure, and the outer wall of the top of the roller shaft 2.1 in a lying position is flush with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com