A silver ingot automatic pouring system

A casting system and automatic technology, applied in casting equipment, equipment for supplying molten metal, metal processing equipment, etc., can solve problems such as uneven artificial casting, and achieve the effects of solving uneven casting, reducing costs and prolonging the life of crucibles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and specific implementation, but it does not limit the present invention.

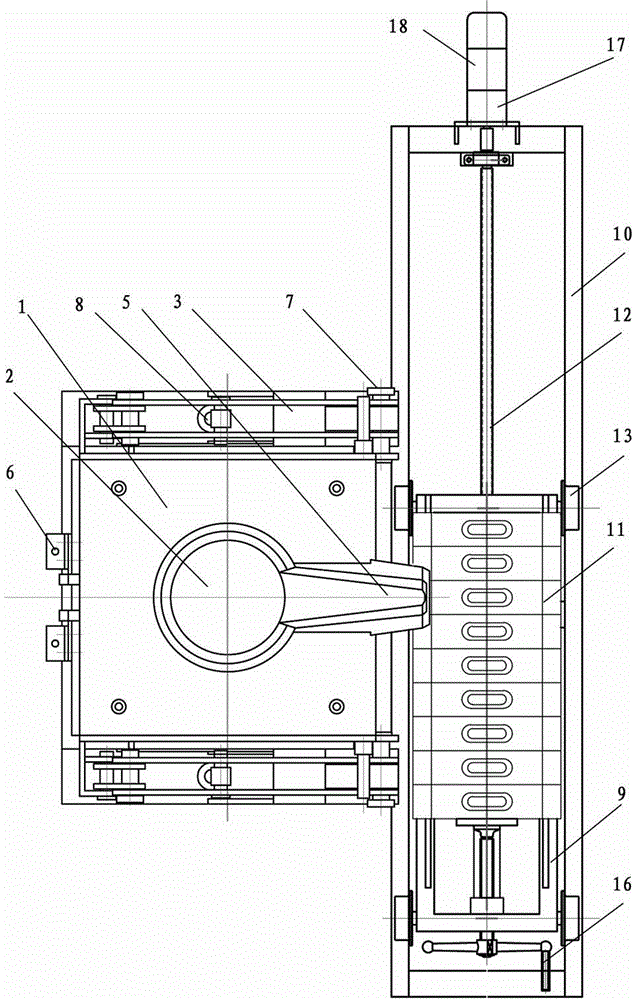

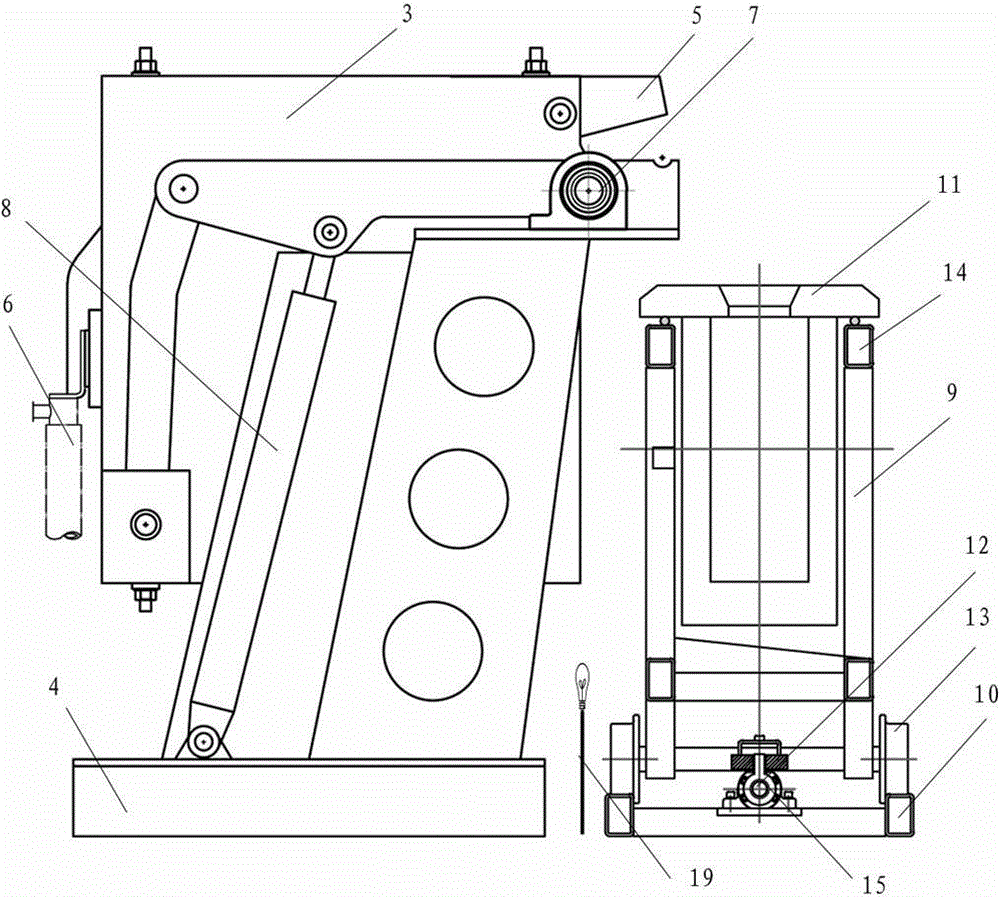

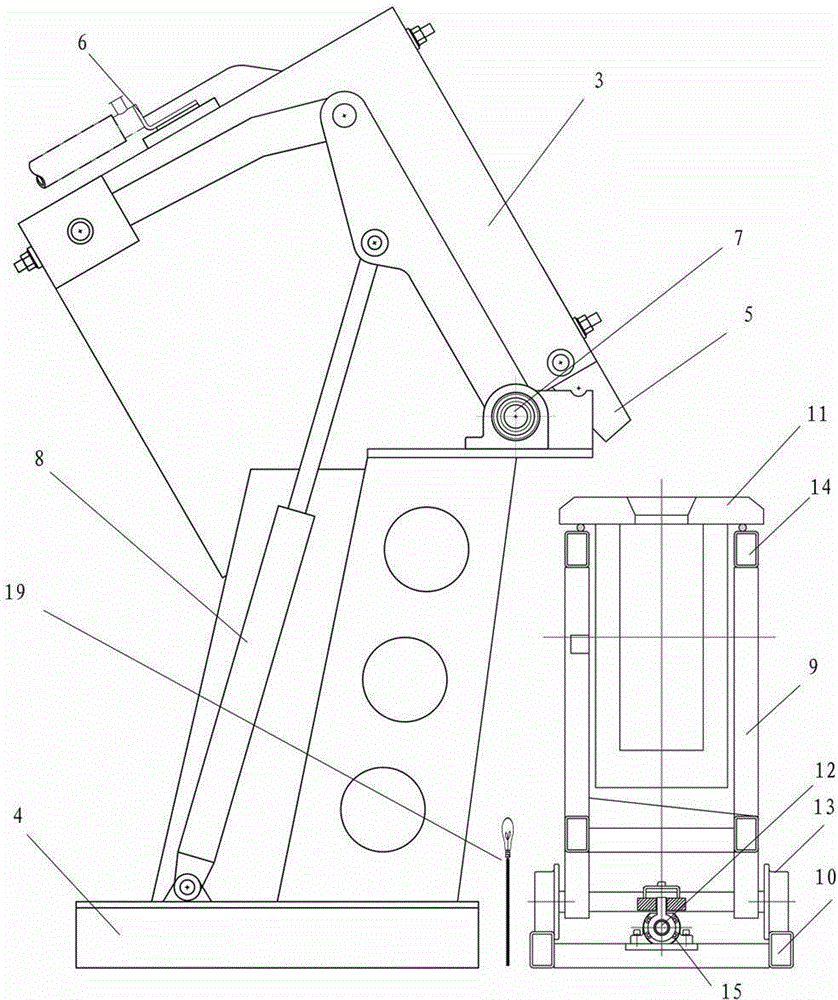

[0012] figure 1 It is a top view structural diagram of a silver ingot automatic casting system, which consists of three parts: a casting machine, an automatic mold positioning machine, and a control system; the casting machine includes an intermediate frequency melting furnace 1, a crucible 2, a furnace frame 3 and a machine base 4. A crucible 2 is placed in the intermediate frequency melting furnace 1, and a casting chute nozzle 5 protrudes from one side of the mouth of the crucible; The access side of the electric lead wire 6 is placed on the left side of the furnace frame 3, and the extension direction of the casting chute nozzle 5 on the crucible is placed on the right side of the furnace frame 3; the intermediate frequency melting furnace 1 is fixed on the furnace frame 3, and the The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com