Brake caliper shell anodic oxidation equipment capable of automatically transferring

An anodizing, automatic transfer technology, applied in anodizing, electrolytic coating, surface reaction electrolytic coating, etc., can solve the problems of manipulator corrosion, volatilization of acid mist, increase in production cost, etc., to avoid corrosion, improve service life, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described below in conjunction with drawings and embodiments.

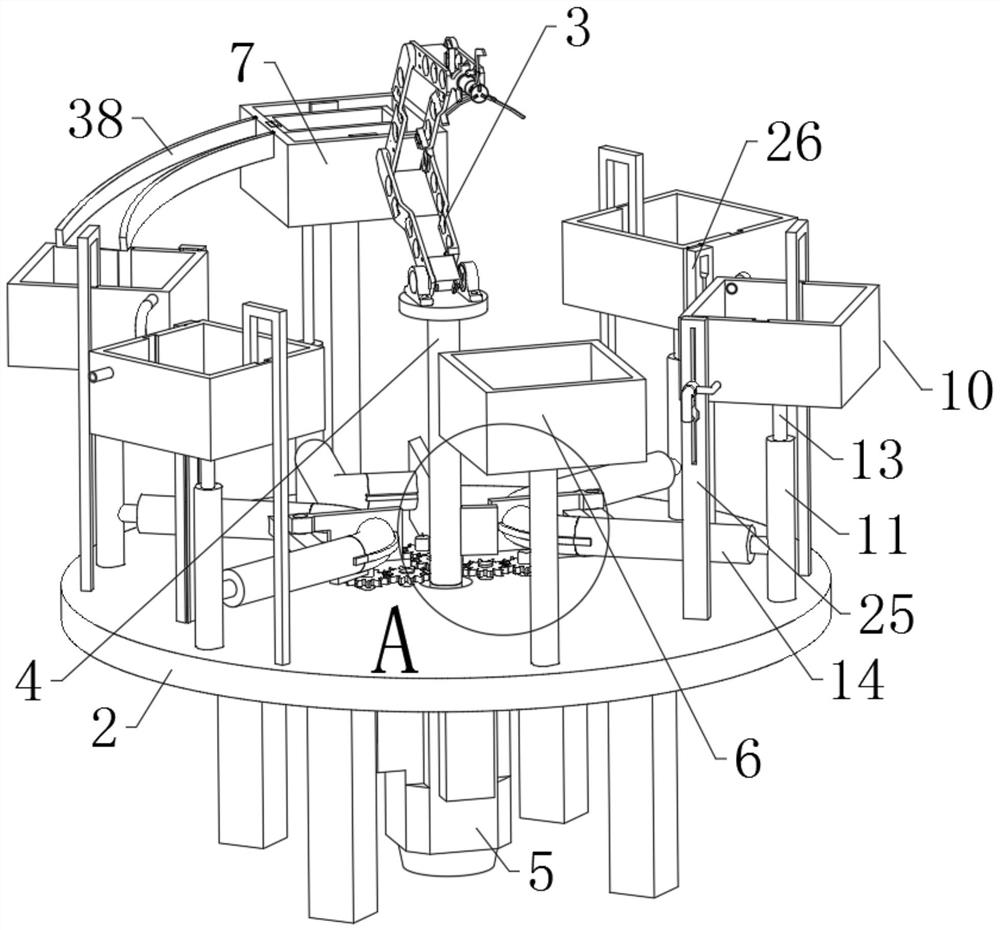

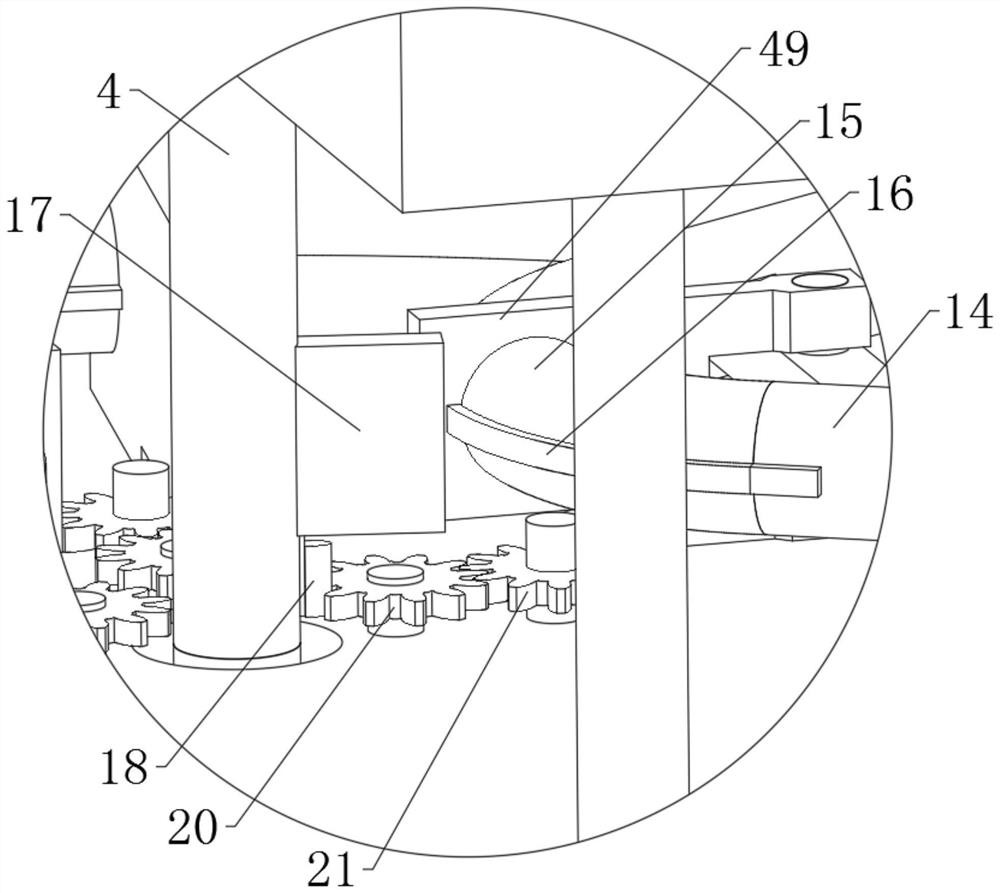

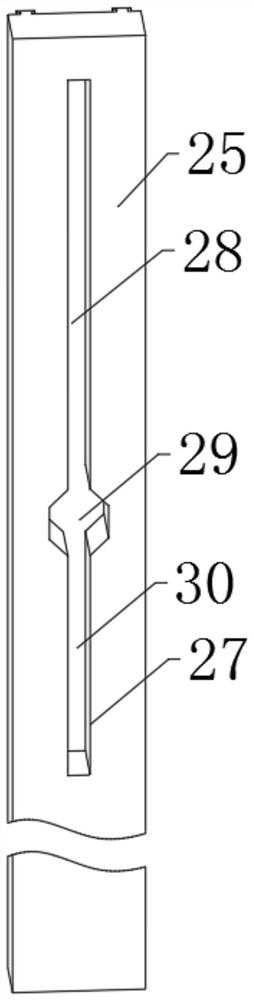

[0056] like Figure 1 to Figure 10 As shown, a brake caliper casing anodizing equipment that can be automatically transferred includes a rotatable transfer unit, and the transfer unit that can clamp the brake caliper casing (1) to be processed drives the brake caliper to be processed The shell (1) enters the degreasing unit, the first water washing unit, the anodizing unit and the second water washing unit in sequence, and a salvageable anodized brake caliper housing is also arranged between the anodizing unit and the second water washing unit When the transfer unit rotates, the transmission unit drives the salvage unit to carry out fishing.

[0057] The transfer unit includes a support plate (2), and the upper end surface of the support plate (2) is rotated to be provided with a manipulator (3) that can clamp the brake caliper housing (1) to be processed. The movemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com