Food package distributing device

A technology of diverting device and food packaging is applied in the field of various forms of diverting devices for food and food packaging diverting device. The effect of high efficiency and food safety, simple structure and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a deeper understanding of the present invention, a specific embodiment is listed below, and the present invention is further described in detail in conjunction with the accompanying drawings.

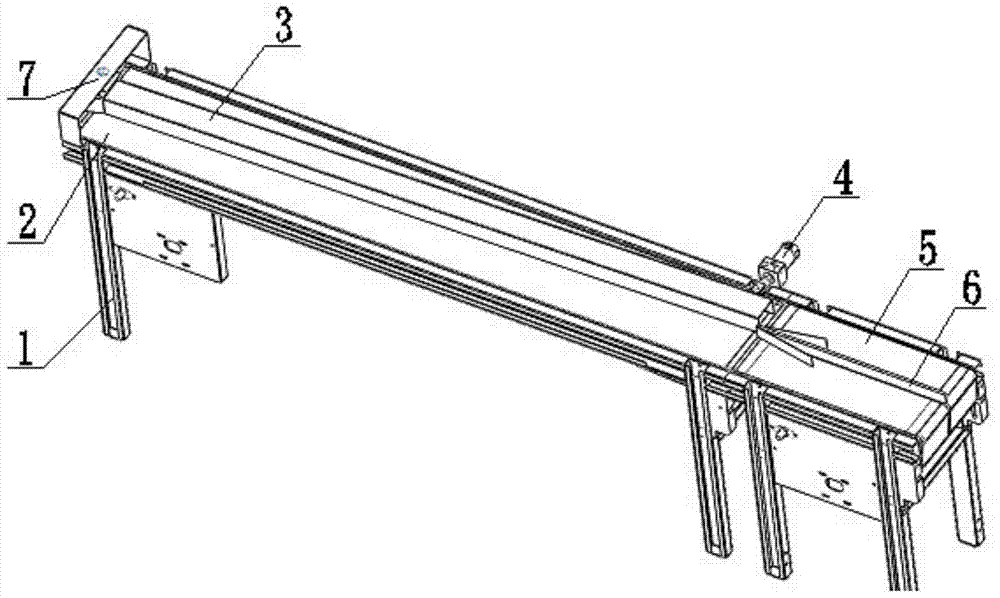

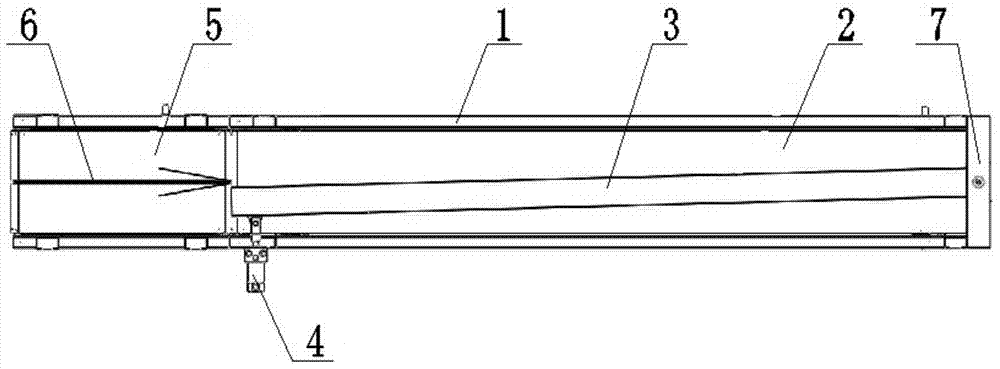

[0023] This embodiment is a kind of bread packaging diversion device, such as figure 1 and figure 2 As shown, it includes a conveying device used to convey bread. The conveying device is provided with a diversion guide device along the direction of food movement. One end of the diversion guide device is fixedly connected to the starting end of the conveying device, and the other end is the movable end and the driving force for it. Drive connection.

[0024] In this example, if figure 1 and figure 2 As shown, the conveying device includes a bracket 1 and a shunt conveyor belt 2 on it, and the shunt conveyor belt 2 is driven by a motor; the shunt guide device is a guide groove 3, and a counter is provided at the end exit of the guide groove 3, and the beginnin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap