Hanging tool for hung conveying spraying line

A spraying line and hanger technology, applied in conveyors, transportation and packaging, load hanging components, etc., can solve problems such as affecting the appearance of paint film adhesion, reducing the production efficiency of spraying lines, and increasing daily maintenance work. The effect of avoiding ineffective cleaning work, small daily maintenance workload and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

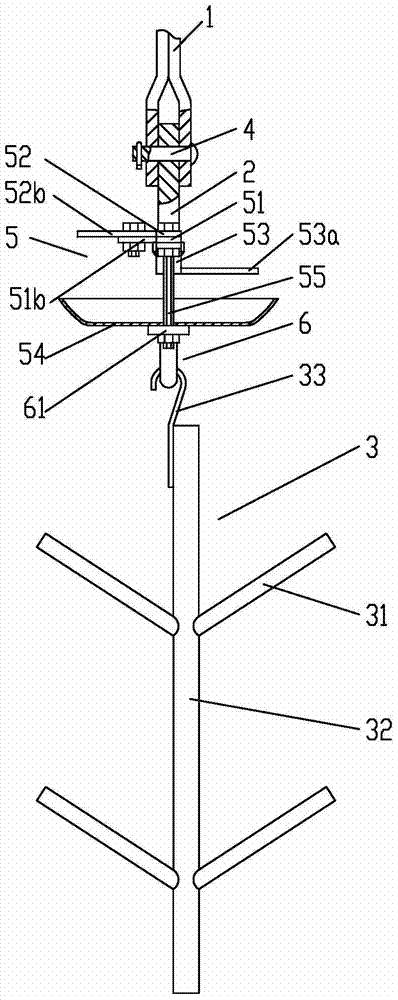

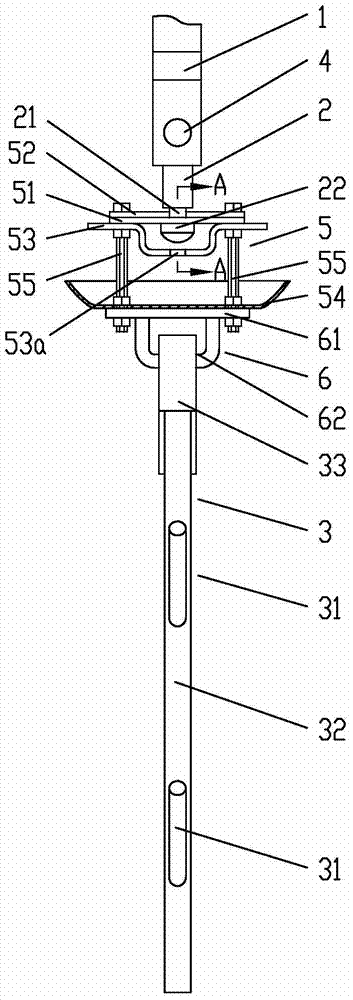

[0027] Example 1 see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6, a hanger used for hanging and conveying a spraying line, comprising a hanger 1, a hanger head 2, and a hanger body 3, the hanger body 3 is provided with two hanging arm groups, and the hanging arm group has two circumferentially symmetrically distributed hanging arms arm 31, the hanging head 2 is connected to the hanging clip 1 through a pin shaft 4 arranged horizontally, the lower part of the hanging head 2 is integrally formed with a journal 21 having a structure of a terminal 22, and the hanging head 2 passes through the shaft The neck 21 and the end 22 are coaxially connected to a hanging basket 5, and the lower end of the hanging basket 5 is connected to the hanger main body 3; the hanging basket 5 includes a beam connected to the hanging head 2, and the beam passes through two ends The connecting screw 55 is connected with an open container-like basket 54; the crossbeam consists...

Embodiment 2

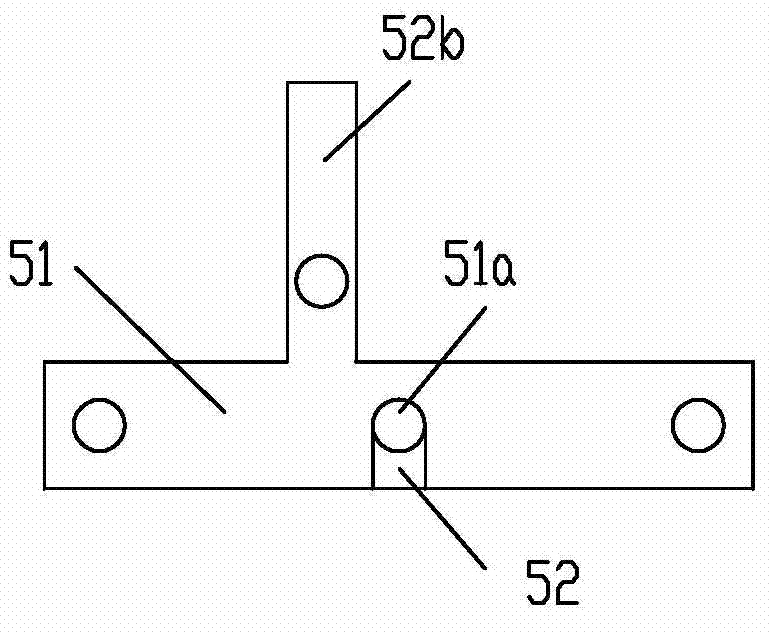

[0029] Example 2 see Figure 7 , Figure 8 , the first crossbeam 51 and the second crossbeam 52 are a left-right combination structure, the main bodies of the first crossbeam 51 and the second crossbeam 52 are strip-shaped, and the two ends of the first crossbeam 51 are provided with a The through hole of the screw rod 55; the middle part of the first beam 51 forms a strip-shaped gap, and the semicircular opening on the first beam 51 is located at the bottom of the gap; the second beam 52 is located in the gap, and the second beam 52 is located in the gap. 52 and the first crossbeam 51 are fixedly connected by bolts and nuts, and the other semicircular opening is formed on the inner side wall of the second crossbeam 52, and two semicircular openings form the connection between the crossbeam 51 and the journal. 21 matching full circle holes. A cantilever arm 51c is provided on the middle side of the first beam 51; a balance arm 53a is suspended from the middle side of the aux...

Embodiment 3

[0031] Embodiment 3 see Figure 9 , Figure 10 , the first crossbeam 51 and the second crossbeam 52 are a left-right combination structure, the main bodies of the first crossbeam 51 and the second crossbeam 52 are strip-shaped, and the two semicircular shapes on the first crossbeam 51 and the second crossbeam 52 are The axis of the opening is located on the joint surface of the two; the through hole of the connecting screw 55 is composed of two semicircular holes distributed on the first crossbeam 51 and the second crossbeam 52; the first crossbeam 51 and the second crossbeam 52 pass through Bolts and nuts secure the connection. A cantilever arm 51d is provided on the middle side of the first beam 51; a balance arm 53a is suspended from the middle side of the auxiliary beam 53, and the balance arm 53a and the cantilever arm 51c are circumferentially symmetrically distributed.

[0032] The rest of the structure of this implementation is the same as that of Embodiment 1 or 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com