Hoist capable of moving universally

A technology of universal wheels and guide grooves, applied in portable lifting devices, switch devices, electrical components, etc., can solve the problems of difficult adjustment of screen cabinets, low installation efficiency, increased workload, etc., and achieve strong detachability , easy to move, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

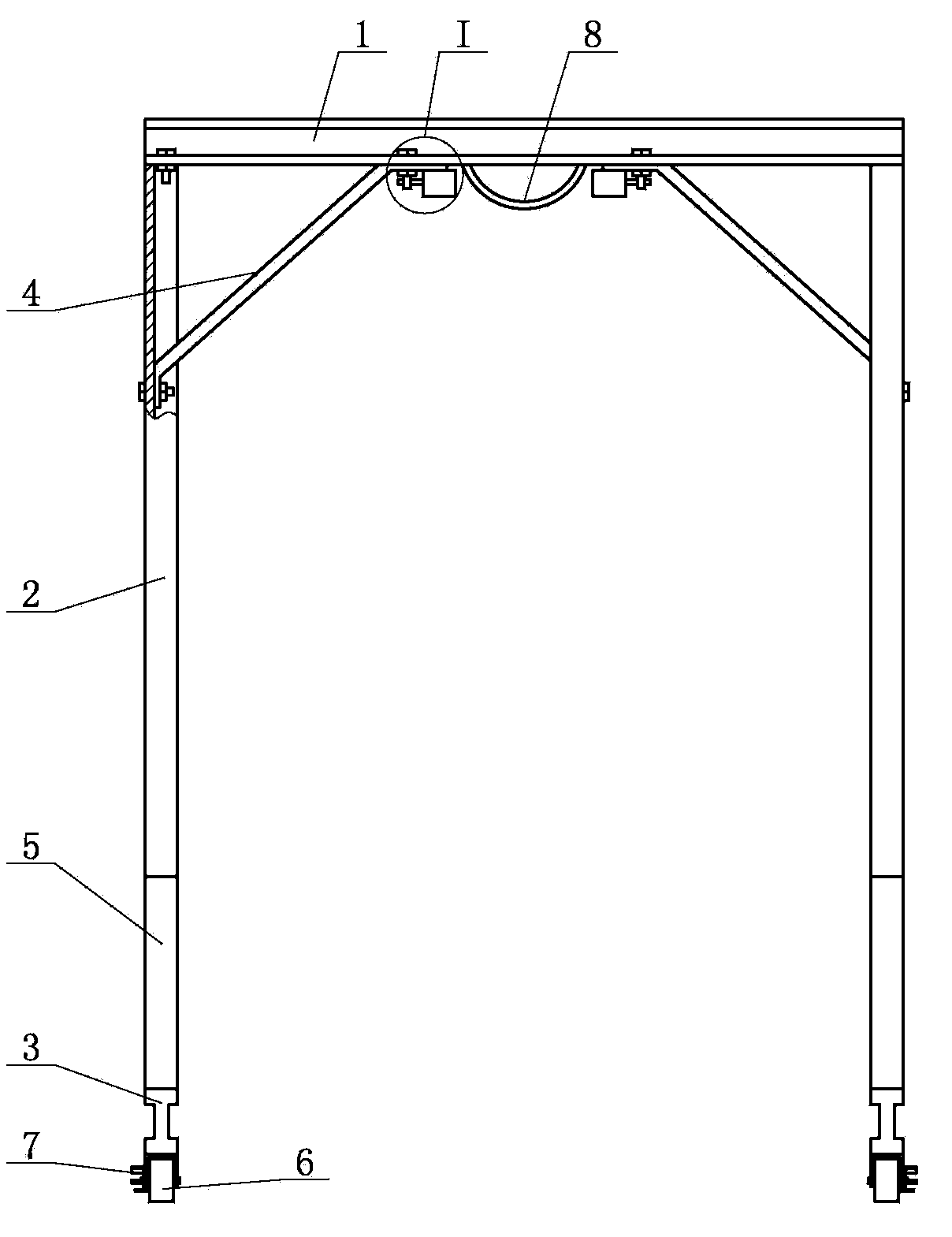

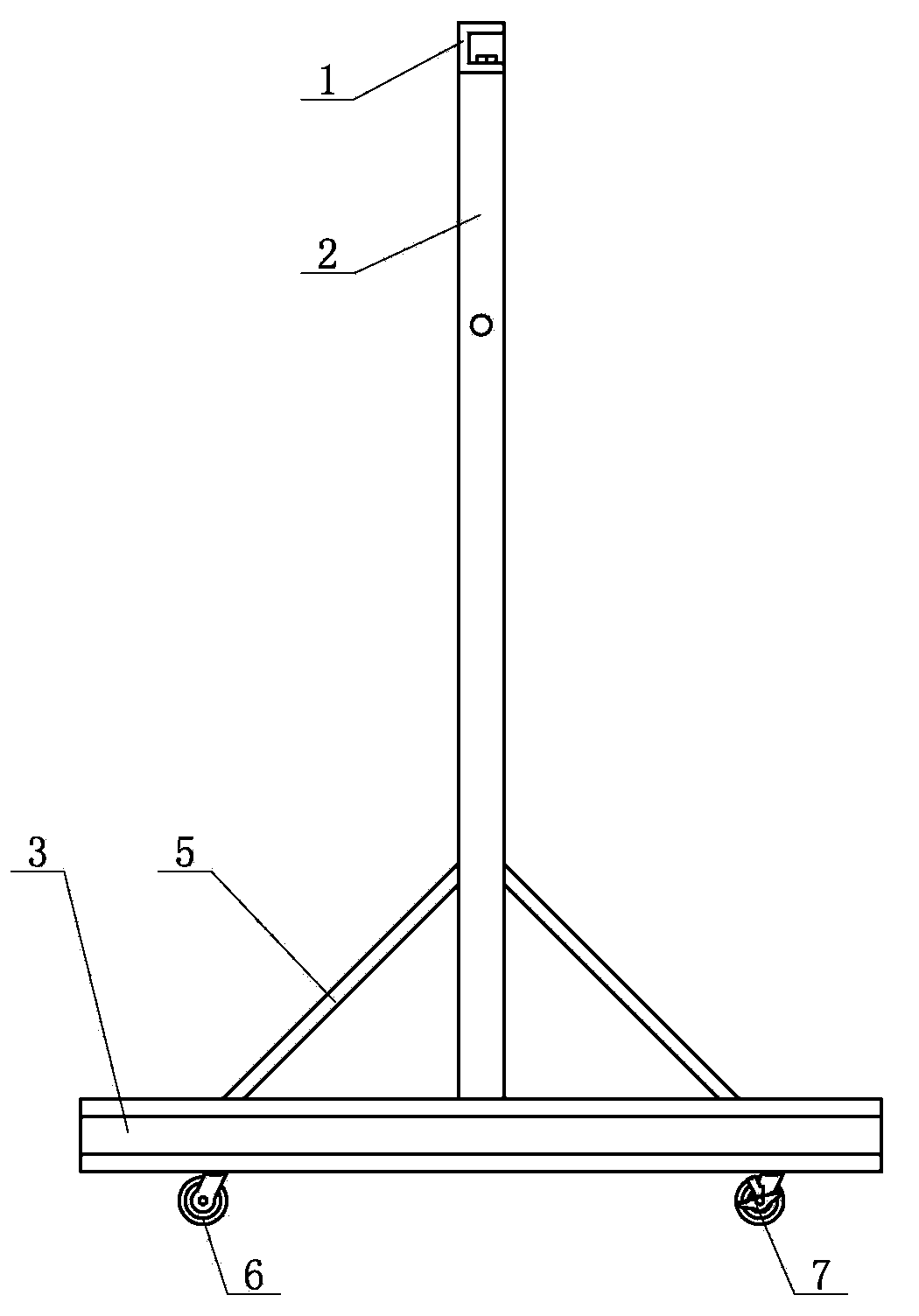

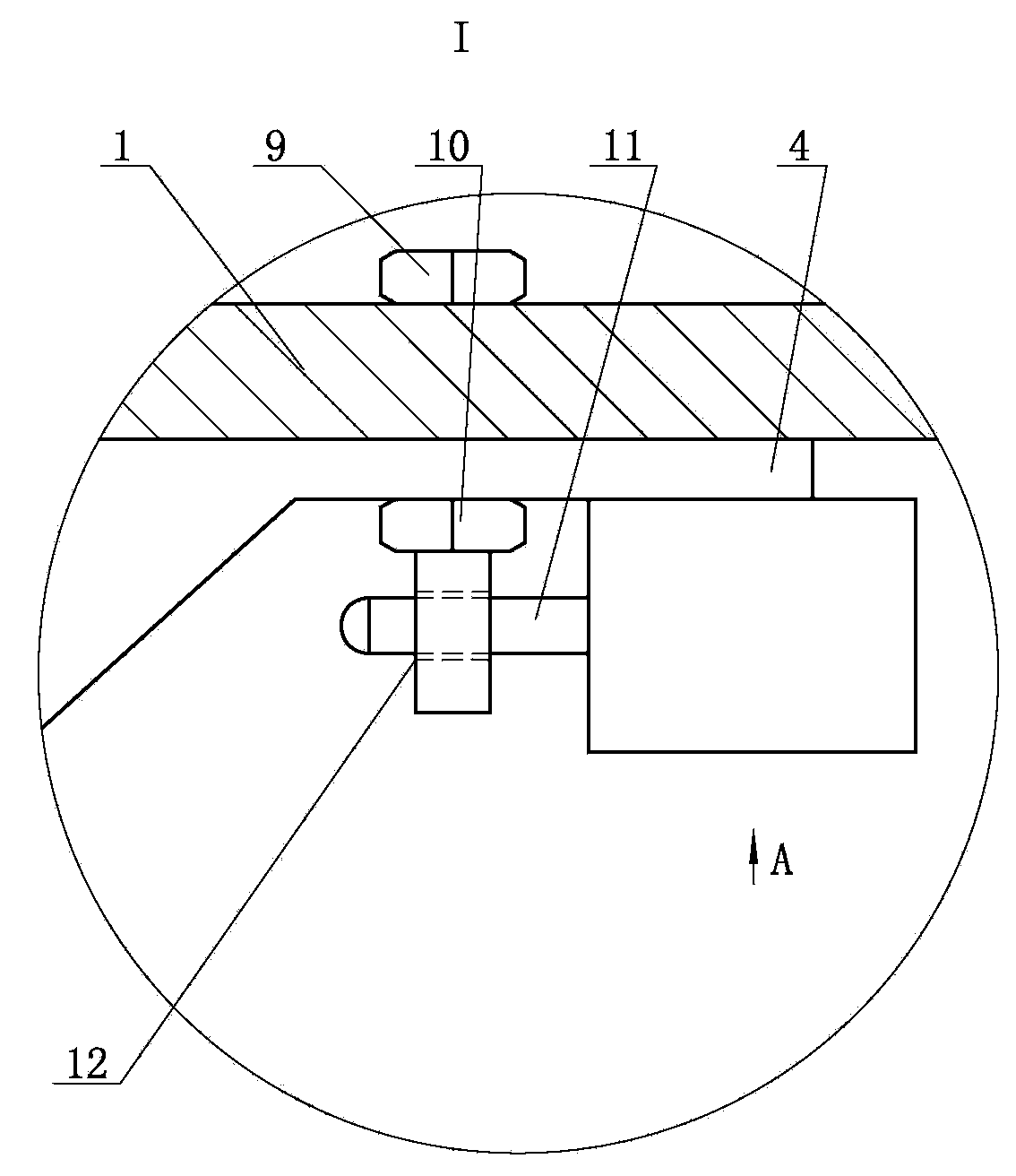

[0008] The universal mobile crane according to the present invention consists of three main parts: beam 1, support 2 and base 3, and the joints of the three parts can be fixed by screws. On the top of the row suspension, the crossbeam 1 is connected with the support 2 with the upper inclined support 4, and screws can be installed at the joint to fix it. At the bottom of the row crane, the base 3 is connected to the support 2 with the lower inclined support 5, and screws can be installed at the connection. Four universal wheels 6 are installed on the hanging base 3, and are fixed on the bottom of the base 3 by screw mounting screws, caster brakes 7 are installed on the universal wheels 6, and the advance and stop of the hanging are controlled with the caster brakes 7. Using the principle of triangular stability, install a pair of universal wheels with disc brakes on the diagonal of the quadrilateral formed by the base, and install ordinary universal wheels on the other diagonal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com