A kind of refining method of abamectin

A technology of abamectin and its refining method, which is applied in the field of biology and medicine, can solve the problems of large toluene loss, environmental pollution, and difficulty in concentration, and achieve the effects of ensuring health, reducing environmental pollution, and improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

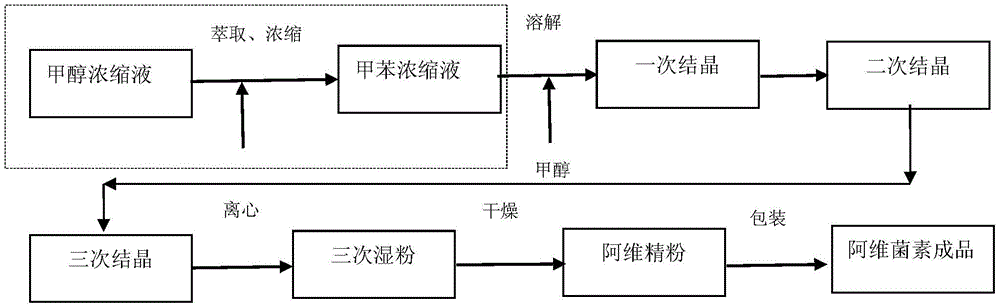

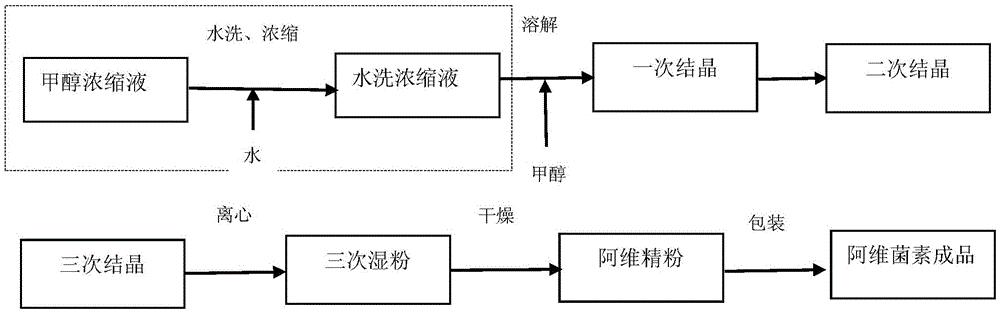

[0018] Take the abamectin fermentation broth, and use a plate frame to separate the solid from the liquid to obtain solid wet mycelium containing abamectin, and the filtrate that does not contain abamectin is sent for environmental protection treatment. The wet mycelium is flash-dried to remove more than 60% of the water to obtain dry mycelium, and the avermectin in the dry mycelia is extracted and dissolved in methanol, and the dried mycelium after extraction is mixed with methanol solution to form a methanol extraction mixture Liquid, the methanol extraction mixture is then separated from the solid and liquid by the dark flow plate frame, the liquid is the methanol extraction solution, and the solid phase is the waste mycelium that does not contain abamectin. The waste mycelium is washed with water to remove residual methanol and sent to environmental protection. The methanol extract is concentrated to remove methanol to obtain the methanol concentrate of abamectin, then add ...

Embodiment 2

[0020] Take the abamectin fermentation broth, and use a plate frame to separate the solid from the liquid to obtain solid wet mycelium containing abamectin, and the filtrate that does not contain abamectin is sent for environmental protection treatment. The wet mycelium is flash-dried to remove more than 60% of the water to obtain dry mycelium, and the avermectin in the dry mycelia is extracted and dissolved in methanol, and the dried mycelium after extraction is mixed with methanol solution to form a methanol extraction mixture Liquid, the methanol extraction mixture is then separated from the solid and liquid by the dark flow plate frame, the liquid is the methanol extraction solution, and the solid phase is the waste mycelia that does not contain abamectin. The waste mycelium is washed with water to remove residual methanol and then sent to environmental protection. The methanol extract is concentrated to remove methanol to obtain the methanol concentrate of abamectin, and t...

Embodiment 3

[0022] Take the abamectin fermentation broth, and use a plate frame to separate the solid from the liquid to obtain solid wet mycelium containing abamectin, and the filtrate that does not contain abamectin is sent for environmental protection treatment. After the wet mycelium is flash-dried to remove more than 60% of the water, the dry mycelium is obtained. The avermectin in the dry mycelia is extracted and dissolved in methanol, and the dried mycelium after extraction is mixed with methanol solution to form a methanol extraction mixture. Liquid, the methanol extraction mixture is then separated from the solid and liquid by the dark flow plate frame, the liquid is the methanol extraction solution, and the solid phase is the waste mycelia that does not contain abamectin. The waste mycelium is washed with water to remove residual methanol and then sent to environmental protection. The methanol extract is concentrated to remove methanol to obtain the methanol concentrate of abamec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap