Pneumatic high-low creel

A creel and frame technology, applied in the field of pneumatic high and low creels, can solve the problems of user inconvenience, inconvenient replacement, high installation requirements, etc., and achieve the effect of convenient disassembly, simple installation, and economical convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

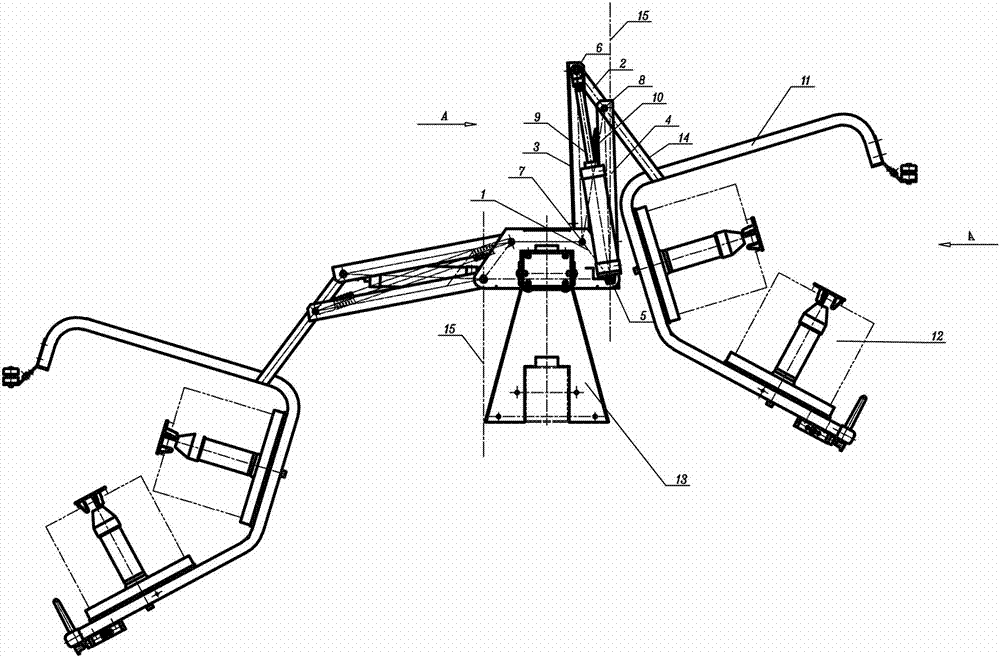

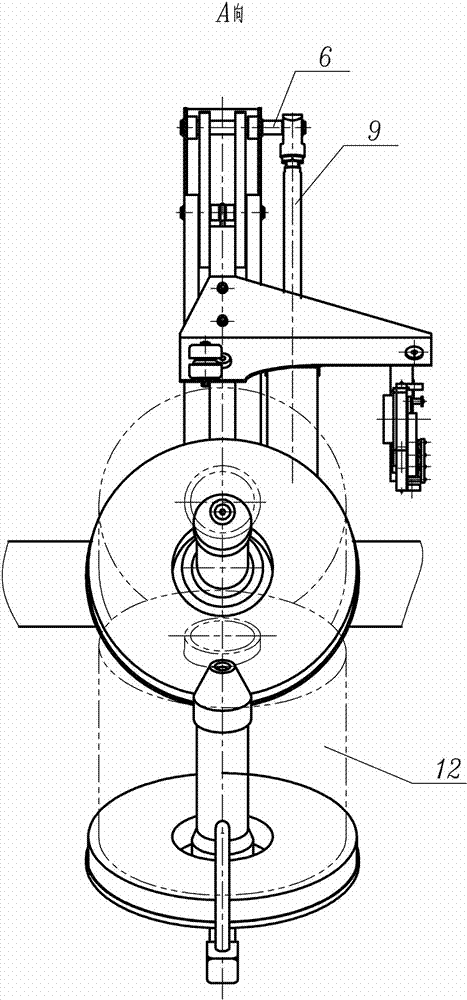

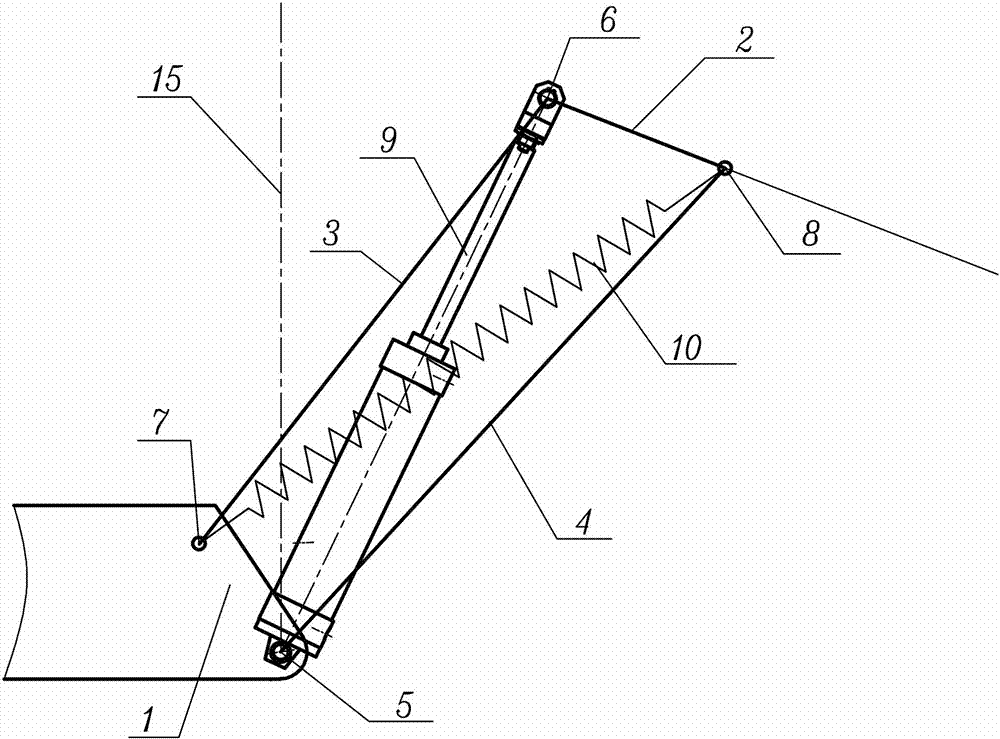

[0021] Such as Figure 1~3 Among them, a pneumatic high and low creel includes a frame 13, and the package frame 11 is supported on the frame 13 through a four-bar linkage mechanism to switch between the yarn loading position and the working position;

[0022] The structure of the four-bar linkage is:

[0023] The third link 3 is hinged with the upper fixed hinge shaft 7 fixed on the frame 13, the fourth link 4 is hinged with the lower fixed hinge shaft 5 fixed on the frame 13, and the second link 2 is hinged through the upper movable hinge shaft 6 is hinged with the third link 3, the second link 2 is hinged with the fourth link 4 through the lower movable hinge shaft 8, and the first link 1 is formed between the upper fixed hinge shaft 7 and the lower fixed hinge shaft 5;

[0024] The cylinder block adopts the cylinder 9 with air intake at both ends. One end of the cylinder 9 is hinged with the lower fixed hinge shaft 5, and the other end is hinged with the upper movable hinge shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com