A frequency adjustable cantilever beam vibration absorber

A cantilever beam and cantilever beam technology, applied in the field of cantilever beam vibration absorbers, to achieve the effect of easy adjustment, easy installation and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

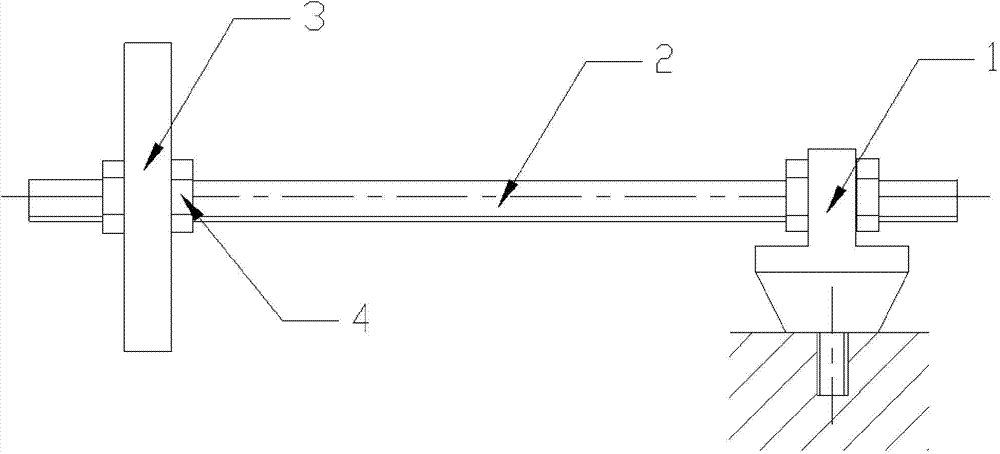

[0017] combine figure 1 , the present invention is made up of base 1, cantilever beam 2, quality disk 3, fixed nut 4. Threads are processed on the cantilever beam 2, and one side is ground flat to make a scale marked with the natural frequency of the vibration absorber, and the scale values are obtained from actual measurements. A nut 4 is fixed at the zero starting point of the scale, and the top of the base 1 passes through the cantilever beam 2, and the other side is fixed with a nut. The mass disc 3 is fixed by a nut 4 on each side, and the reading is based on the outer surface of the outer fixing nut, and the displayed value is the current natural frequency of the vibration absorber. The working length of the cantilever beam 2 can be adjusted freely, and the operation is simple. The vibration-absorbing body is a cantilever beam structure. Threads are pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com