Wind-tunnel balance body shafting static correction system and wind-tunnel balance body shafting static correction method

A wind tunnel balance and body shafting technology, which is applied in measuring devices, instruments, aerodynamic tests, etc., can solve the problems of inability to eliminate error sources, complex structure, low efficiency, etc., achieve simple and feasible accuracy, and improve static calibration efficiency. , the effect of shortening the calibration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] It should be noted in advance that the system and method for static calibration of the shaft system of the wind tunnel balance body provided by the present invention will be simultaneously described below in order not to feel redundant.

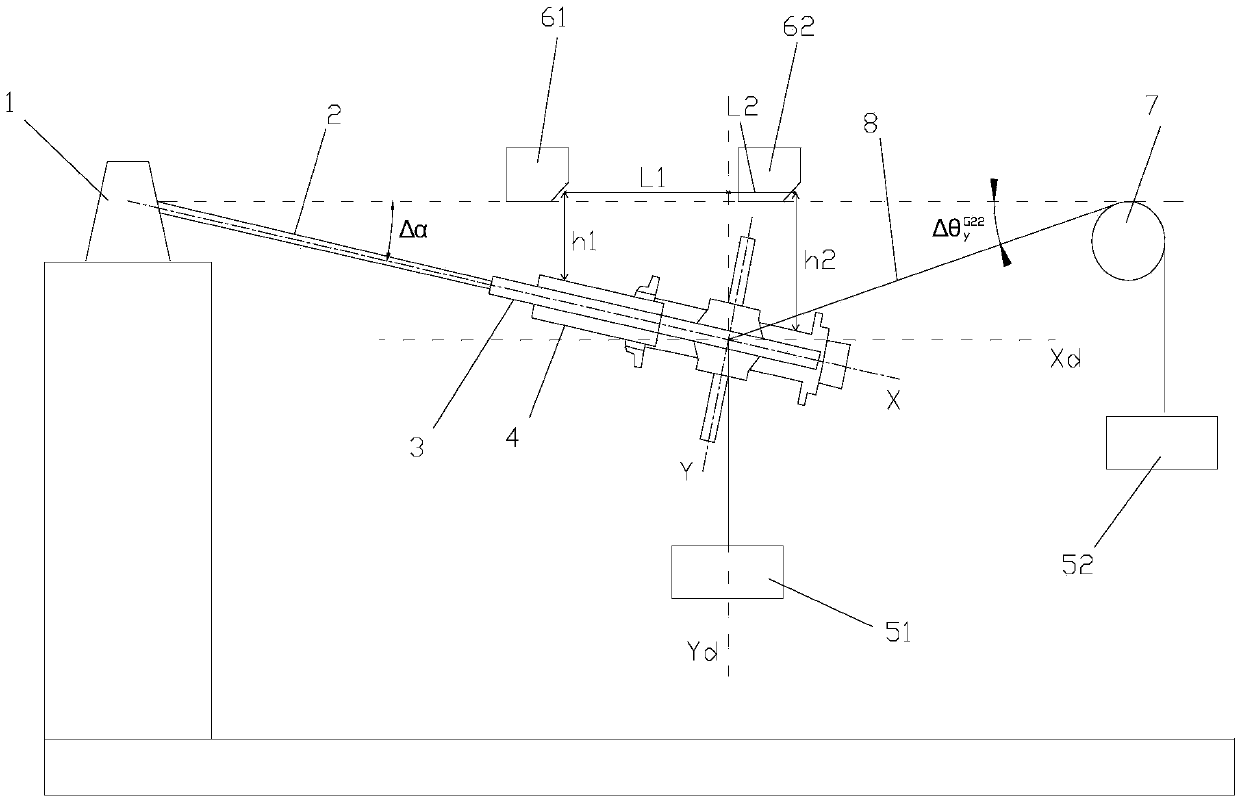

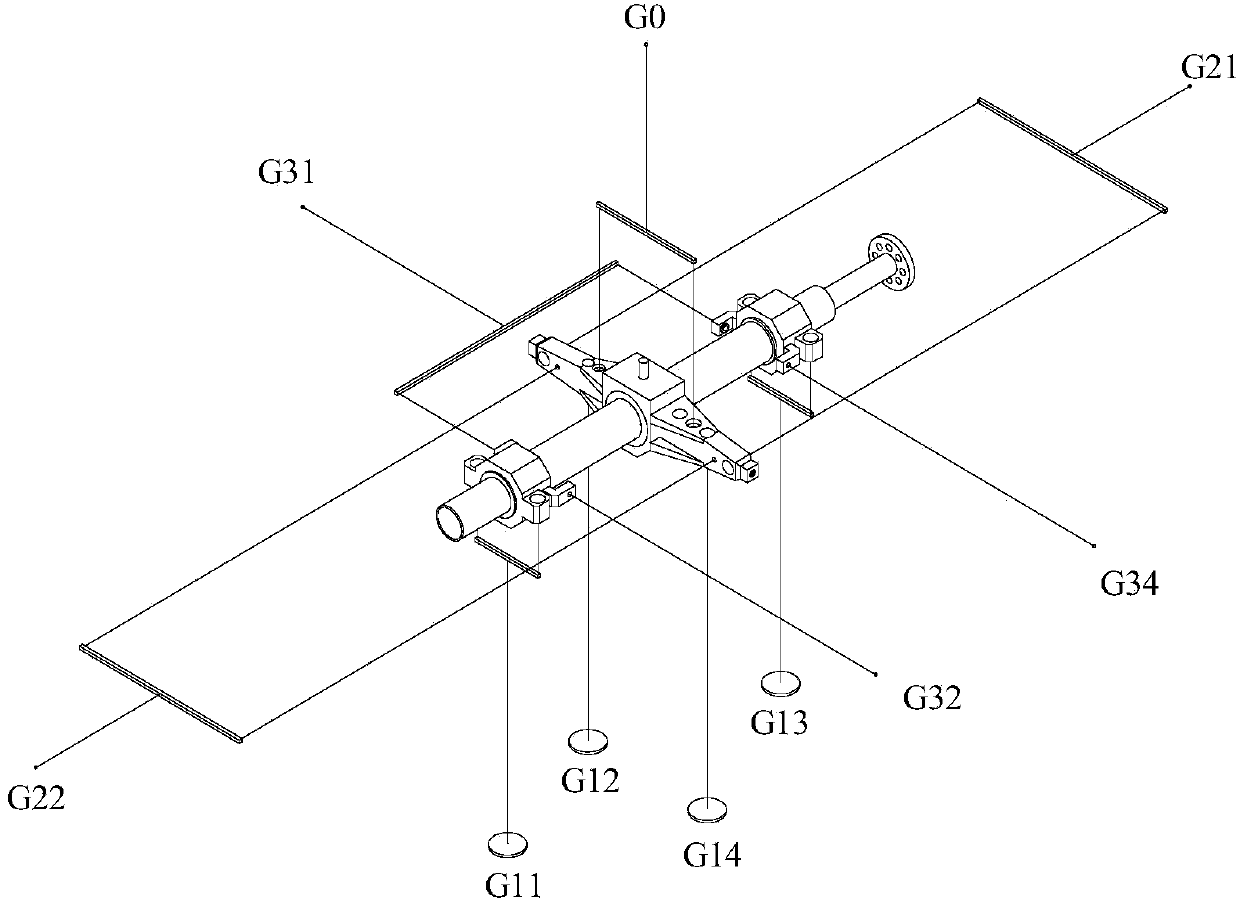

[0020] Such as figure 1 As shown, the embodiment of the wind tunnel balance shaft system static calibration system of the present invention mainly includes a base 1, a strut 2, a loading head 4, a displacement sensor, a load generating device, and a device connected between the loading head 4 and the load generating device. connectors. Preferably, the displacement sensor is a laser displacement sensor, such as laser displacement sensors 61, 62; the load generating device is a weight, such as weight 51, weight 52, so if necessary, a pulley 7 etc. should be set to change the pulley 8 The direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com