Rotating electromagnet

A technology of rotating electromagnets and yokes, applied in the field of electromagnets, can solve the problems of high coil power, poor economy, large volume and weight, etc., and achieve the effects of large output torque and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

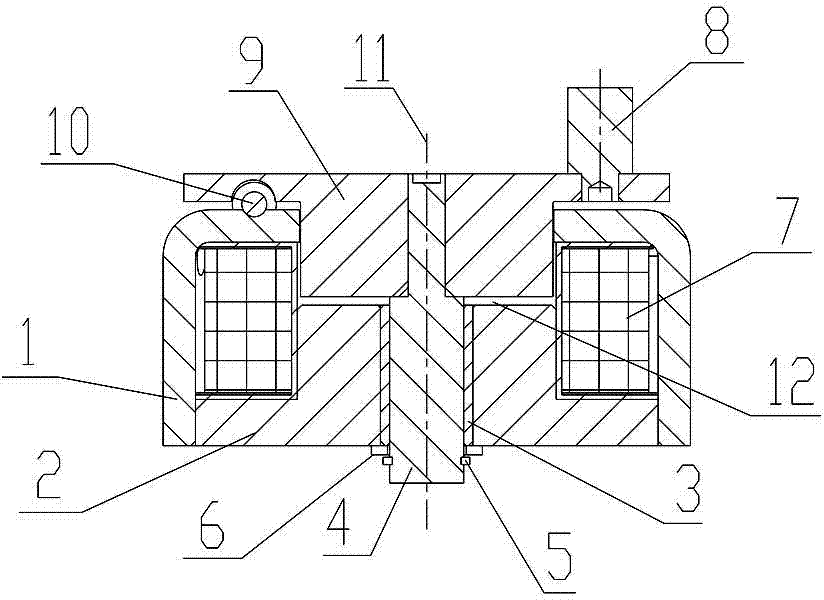

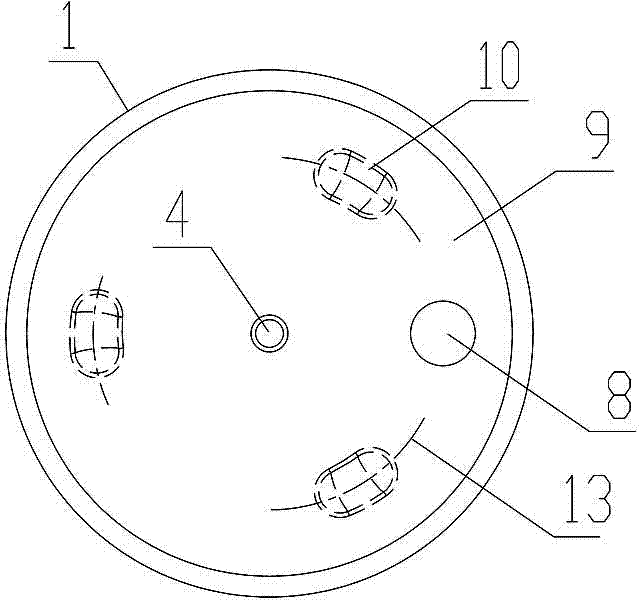

[0009] Such as figure 1 , 2 As shown, the rotary electromagnet of the present invention is composed of a yoke 1, an iron core 2, an armature 9, a coil 7, and a ball 10; the yoke 1 is an inverted U structure with a jack on the top surface, and the The top surface of the inverted U structure yoke 1 is uniformly provided with three upper opening arc-shaped grooves distributed along the circumferential direction. The cross-section of the upper opening arc-shaped groove is arc-shaped, and the center of the upper opening arc-shaped groove The line 13 has a helical structure relative to the longitudinal centerline 11, and the two ends of the arc-shaped groove on the upper opening are spherical surfaces tangent to the bottom surface of the groove; the iron core 2 is provided in the inverted U structure yoke 1 with a central hole The first stepped shaft, the diameter of the upper end of the first stepped shaft is smaller than the diameter of the lower end; the armature 9 is a second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com