Low-cost miniature single-phase permanent magnet brushless direct current motor

A DC motor, single-phase permanent magnet technology, applied in electromechanical devices, electrical components, etc., can solve problems such as reducing operating effects, increasing vibration and noise, and operating torque fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

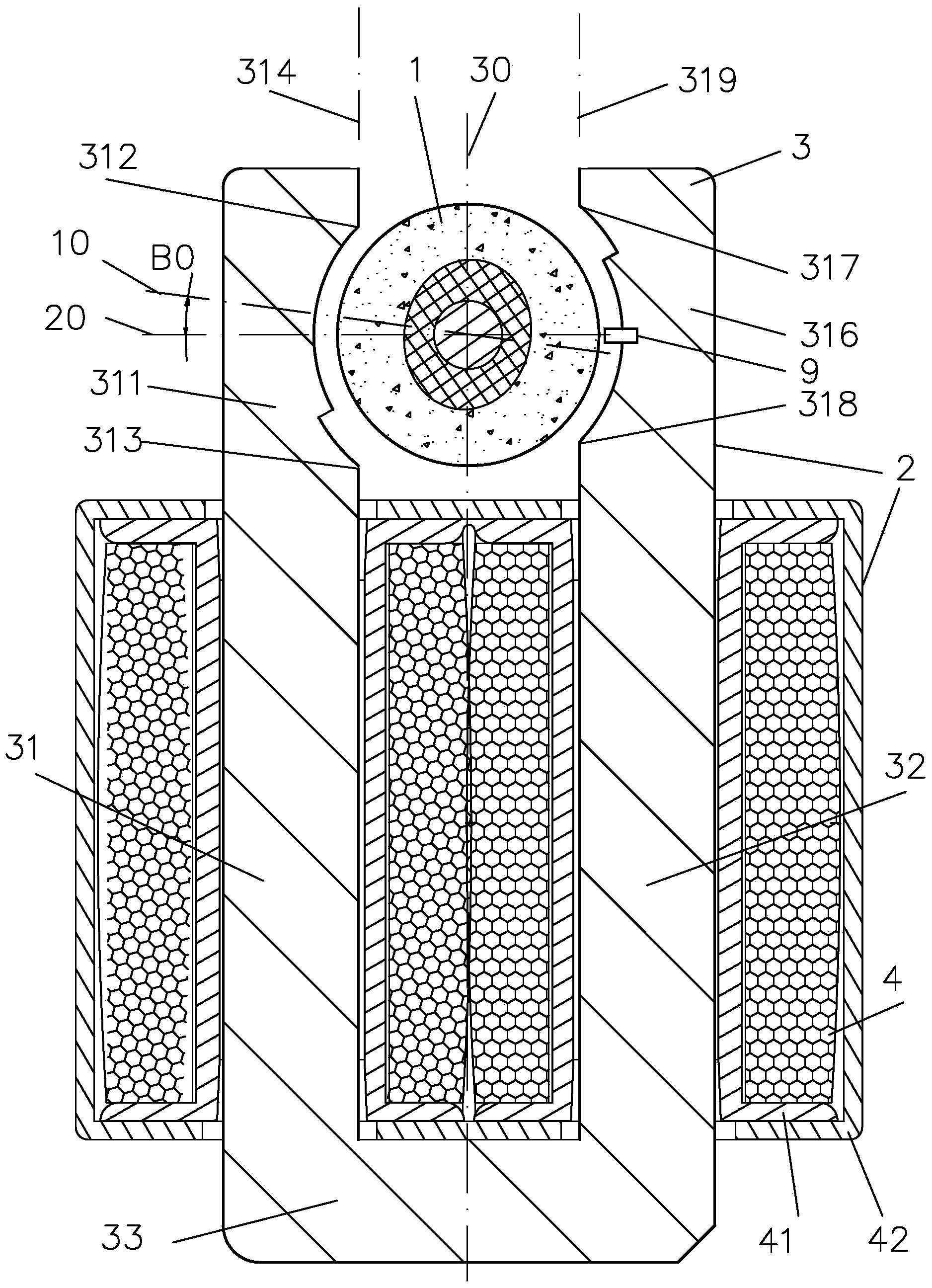

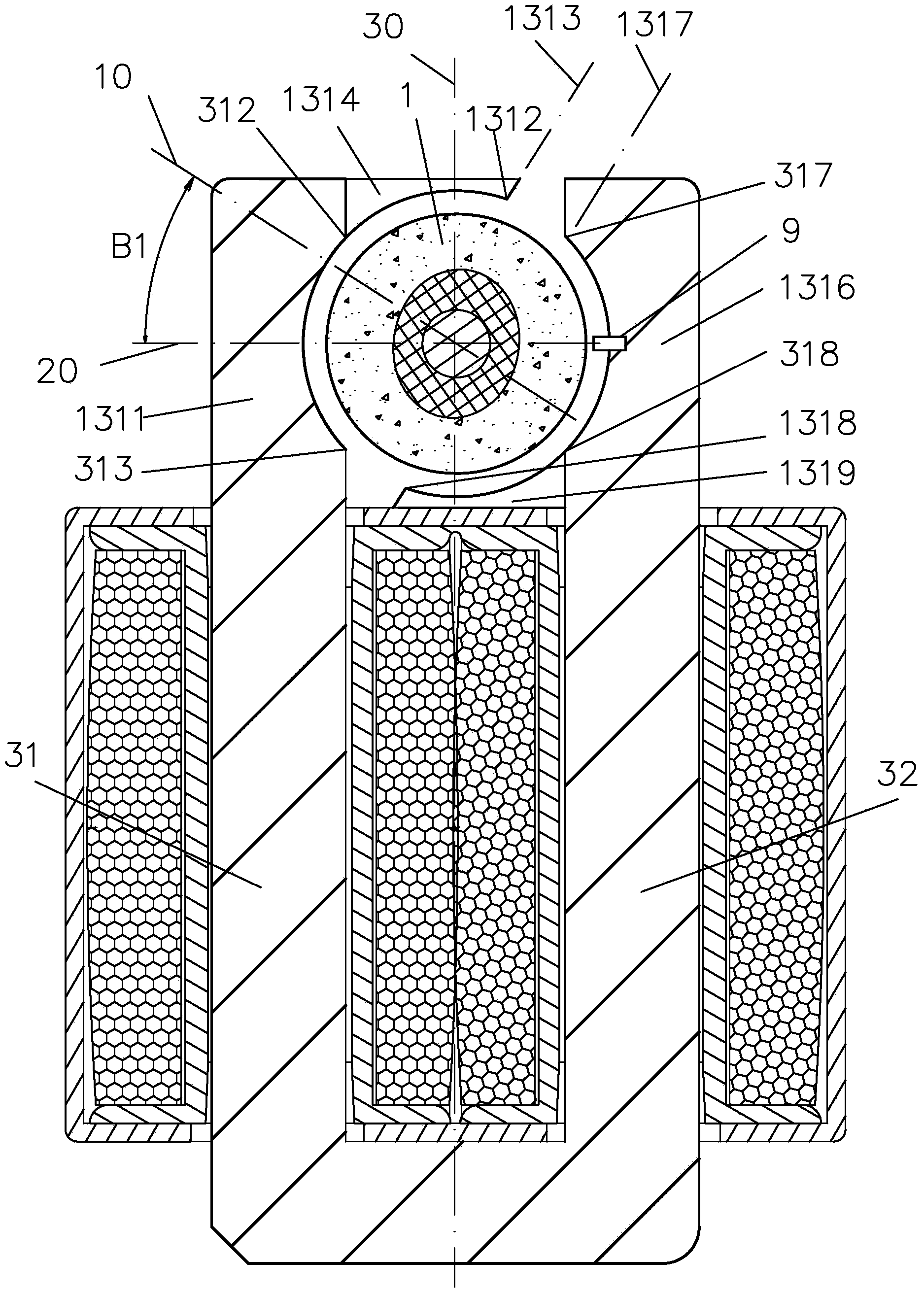

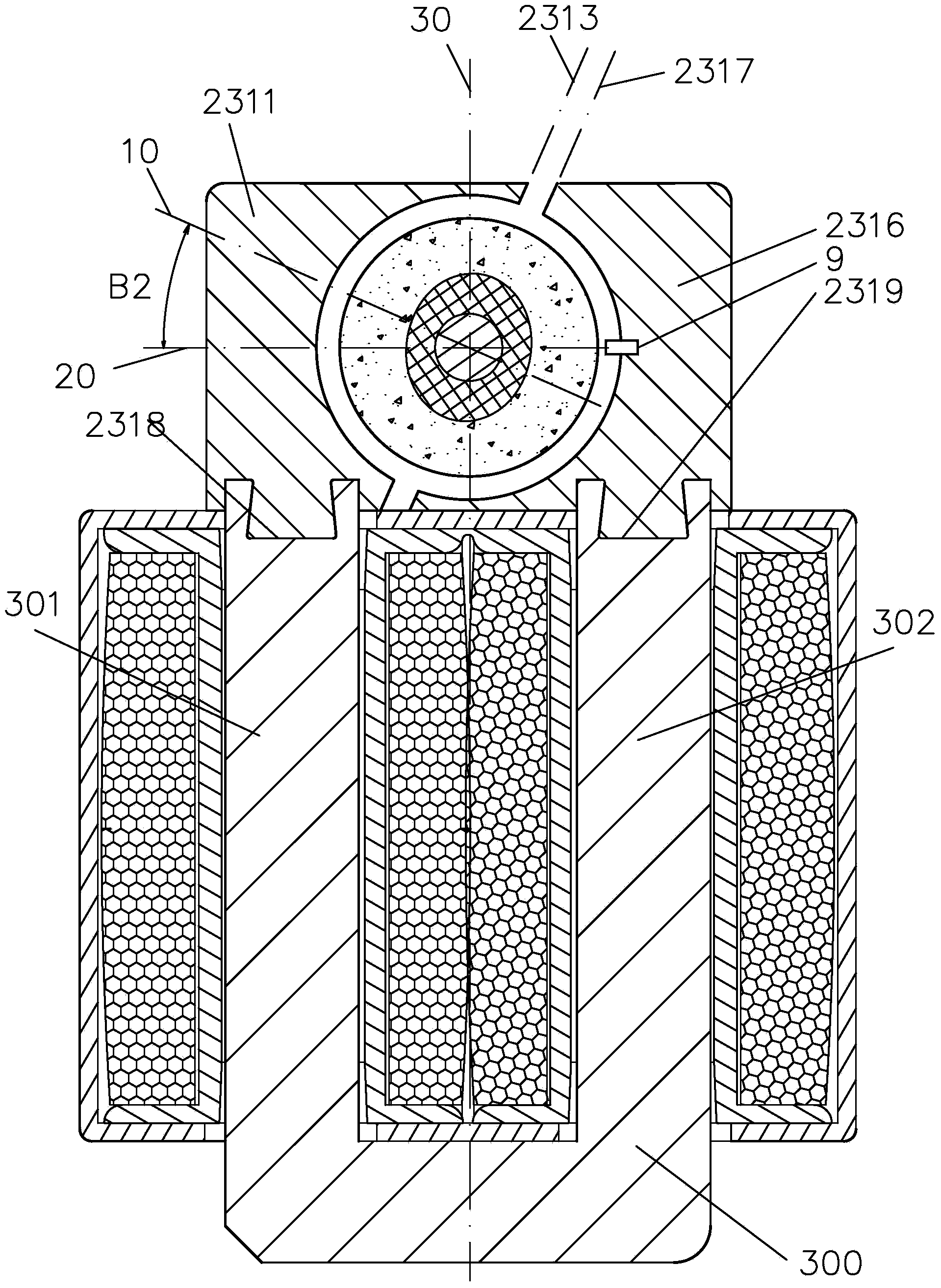

[0021] The motor of the embodiment of the present invention is improved on the basis of the miniature single-phase permanent magnet brushless DC motor using a "U"-shaped iron core in the prior art described in the background art. The basic structure of the motor in the prior art is as figure 1 shown, including:

[0022] - Cylindrical permanent magnet rotor 1 magnetized at two radial poles;

[0023] — Stator 2, including "U"-shaped laminated iron core 3 and stator winding 4; when the motor is in use, the input end of stator winding 4 is connected to a DC power supply, including a modulating (such as PWM) DC power supply required for speed regulation;

[0024] ——The Hall element 9 installed on the stator magnetic field axis 20 close to the circumference of the permanent magnet rotor 1 , which senses the signal of the magnetic pole position of the permanent magnet rotor 1 to control the DC power supply to the stator winding 4 . Position sensors such as inductive or photoelectri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com