Stamping method

A technology of stamping forming and stamping device, which is applied in the field of stamping and forming method of raw materials, can solve the problems of material fracture forming, insufficient material inflow, defectiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

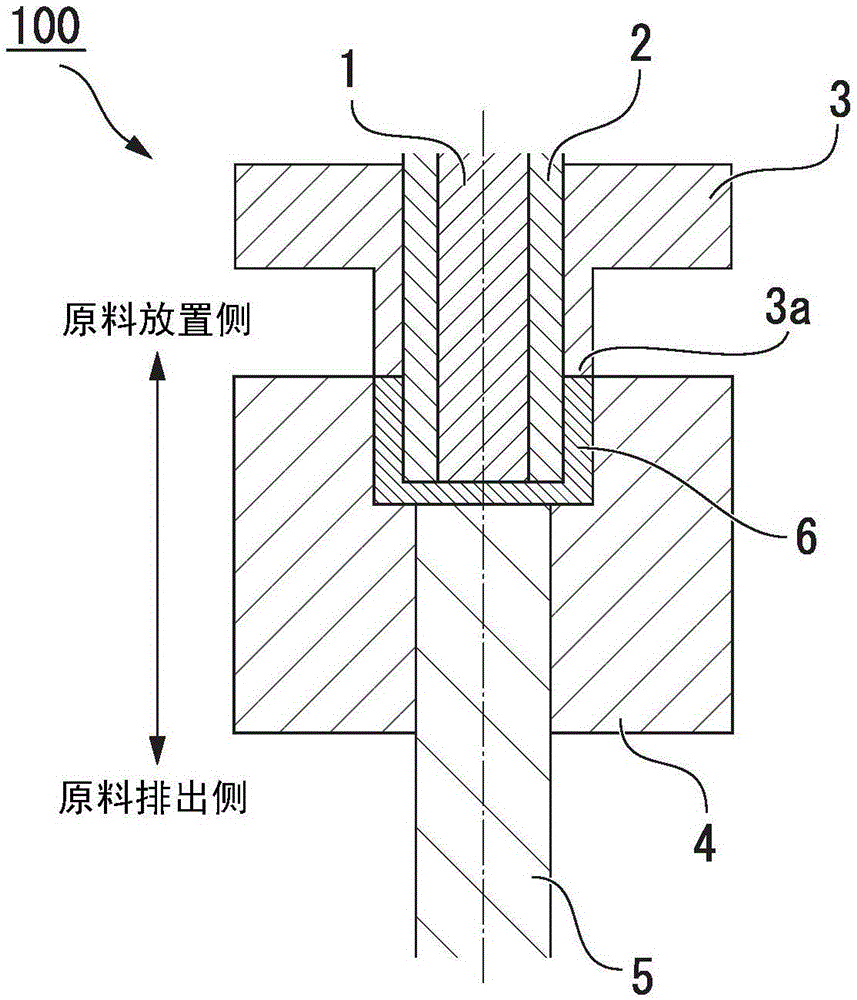

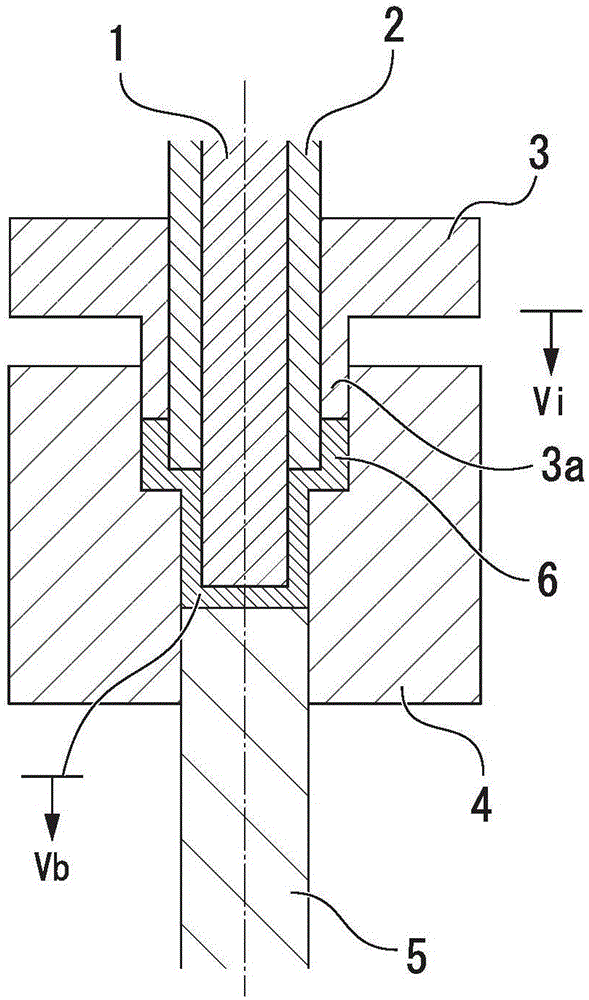

[0056] use Figure 1A ~ Figure 1C In the shown multi-axis press device, a carbon steel cup-shaped raw material with an outer diameter of φ90mm×wall thickness 2mm×height 30mm is formed into a cup with an outer diameter of φ50mm at room temperature while maintaining a wall thickness of 2mm. In this molding, the multi-axis punching device is set so that before and after (before and after filling) the raw material confirmed by preliminary molding is filled toward the inside of the mold, in any case the lowering of the outer peripheral punch 3 The ratio Vb / Vi of the velocity Vi to the descending velocity Vb of the punch has the same value. Table 1 shows the relationship between the speed ratio Vb / Vi in this molding and the molding result.

[0057] When the speed ratio Vb / Vi is in the range of 0.7 to 1.5, the molding is completed without breaking and burring the raw material. On the other hand, when the speed ratio Vb / Vi is less than 0.7, burrs which become a problem in product ma...

Embodiment 2)

[0061] use Figure 1A ~ Figure 1CThe shown multi-axis punching device molds an aluminum cup-shaped raw material with an outer diameter of φ120mm×wall thickness of 5mm×height of 40mm into a cup with an outer diameter of φ70mm at room temperature while maintaining a wall thickness of 5mm. In this molding, the multi-axis press device is set so that the ratio of the descending speed Vi of the outer peripheral punch 3 to the descending speed Vb of the punch before and after filling the mold with the raw material confirmed by preliminary molding is Vb / Vi are different values. Table 2 shows the relationship between the speed ratio Vb / Vi of the multi-axis press device and the molding results during the molding.

[0062] When the speed ratio Vb / Vi is in the range of 0.7 to 1.5 both before and after filling, molding is completed without causing breakage and burrs in the raw material. On the other hand, when the speed ratio Vb / Vi is a value smaller than 0.7 both before and after fillin...

Embodiment 3)

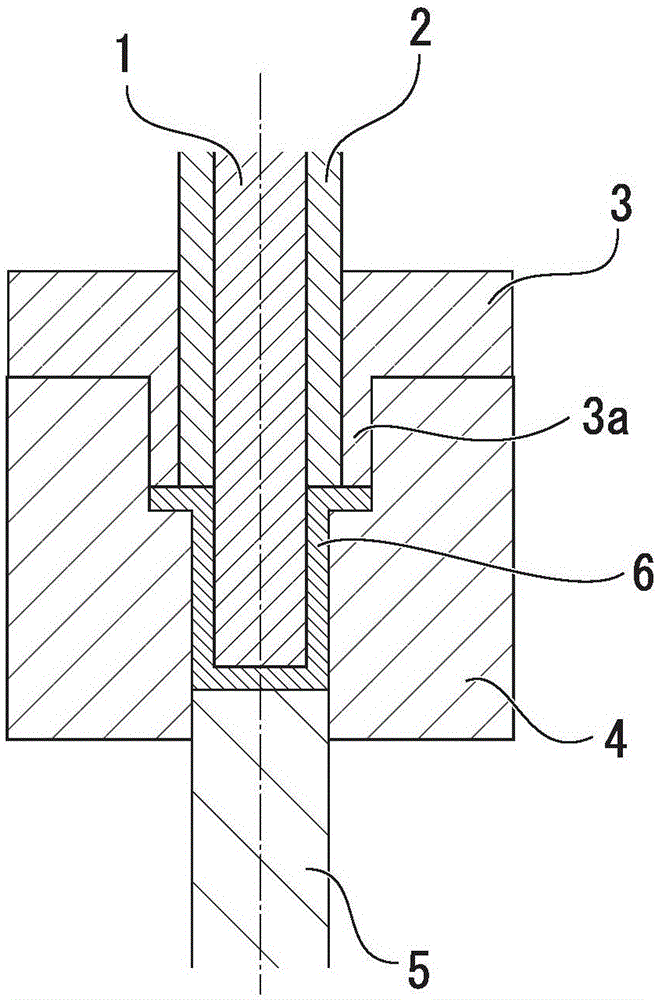

[0066] Further, use Figure 1A ~ Figure 1C The shown multi-axis punching device molds a carbon steel cup-shaped raw material with an outer diameter of φ80mm×wall thickness of 5mm×height of 45mm into a cup with an outer diameter of φ45mm at room temperature while maintaining a wall thickness of 5mm. Table 3 shows the relationship between the sum s of the gaps between the raw material 6 , the female mold 4 , and the anti-wrinkle device 2 during the molding, and the molding results.

[0067] [table 3]

[0068]

[0069] The gaps in Table 3 are in the Figure 3A The value obtained by dividing the sum s of gaps (gap in the horizontal direction) formed between the raw material 6 , the female mold 4 and the anti-wrinkle device 2 in the illustrated state by the plate thickness dimension t of the raw material 6 .

[0070] When the velocity ratio Vb / Vi was in the range of 0.7 to 1.5 before and after filling, molding was completed without causing breakage and burrs in the raw materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com