Steel wire for high-tension bolts and method for manufacturing high-tension bolts

A technology of high-strength bolts and manufacturing methods, which is applied in the direction of bolts, screws, threaded fasteners, etc., can solve problems such as the incidence of defective bolts, uneven resistance to delayed failure of high-strength bolts, and uneconomical problems, and achieve the elimination of delayed failure Good non-uniformity, anti-sintering, and the effect of avoiding breakage and bite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The best mode for carrying out the present invention will be described below with reference to the drawings.

[0020] (1) Application of lubricating film

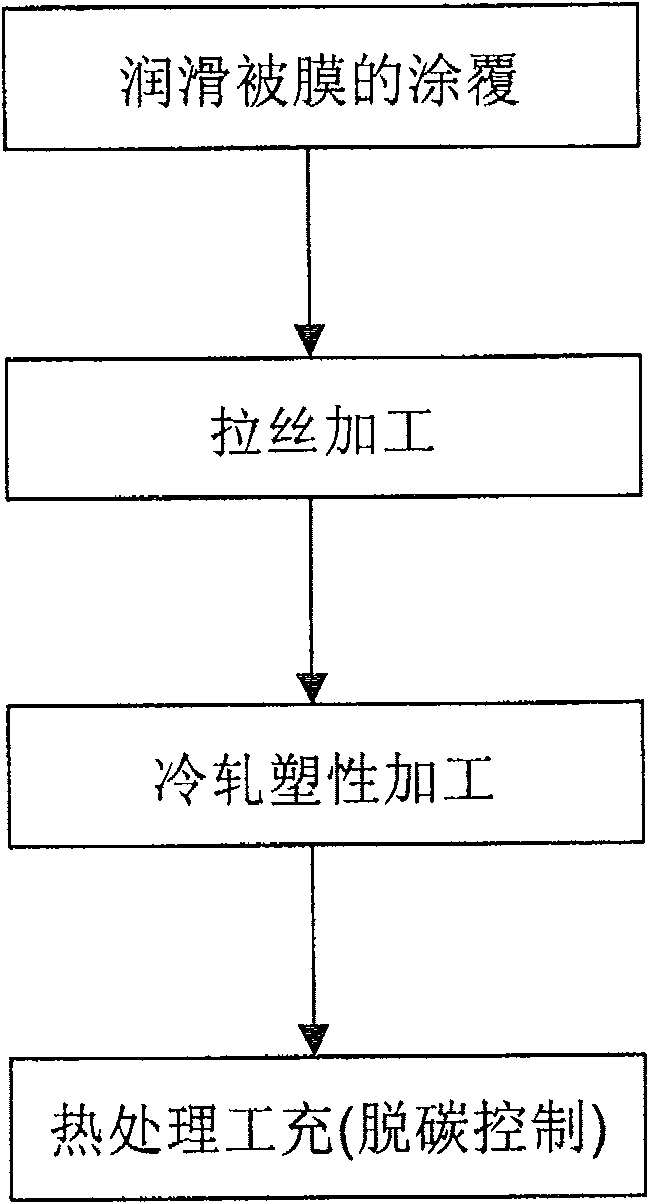

[0021] Such as figure 1 As shown, when high-strength bolts are manufactured using steel wire for high-strength bolts as a base, steel wires such as SCM435, 440H and boron steel are coated with a lubricating film and then drawn to a specified diameter. Furthermore, cold-rolled plastic processing is performed so that the overall shape of the bolt head and the bolt shaft portion appears, and the semi-finished bolt is heat-treated. Finally, the thread is threaded on the shaft of the bolt to obtain a high-strength bolt.

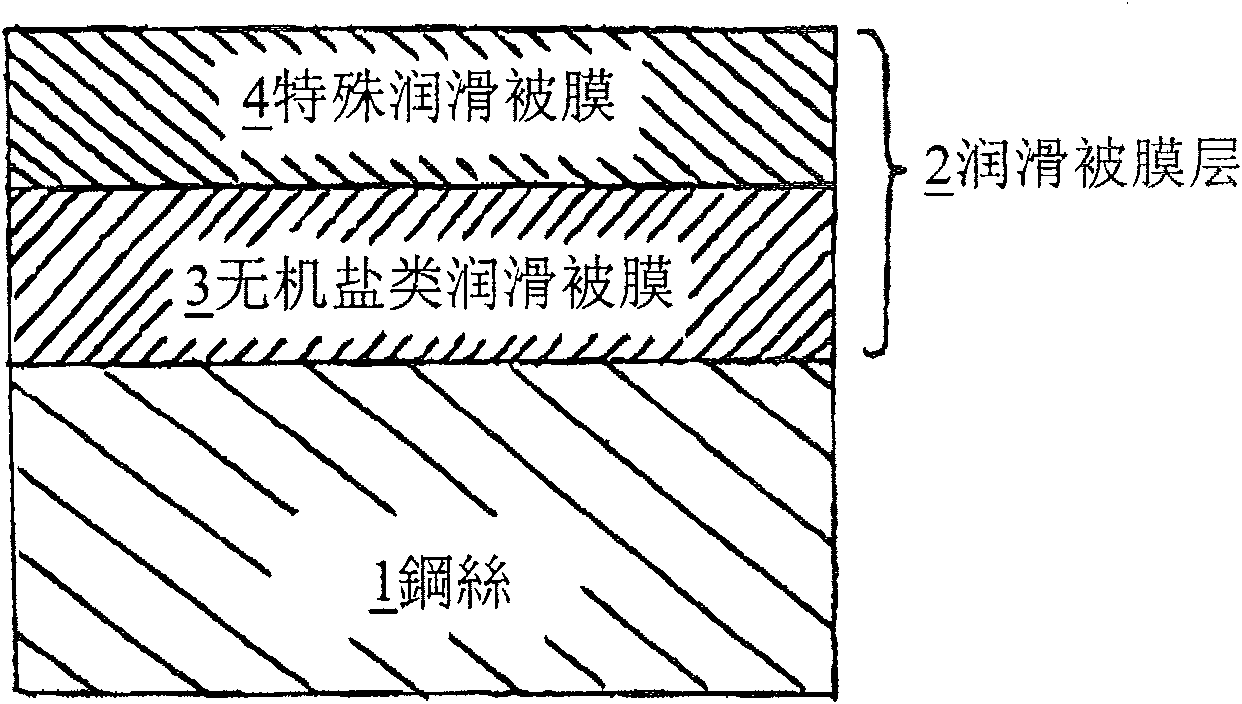

[0022] The present invention as figure 2 As shown, the surface of the steel wire 1 is coated with a lubricating coating layer 2 of a multi-layer structure that has never been seen before.

[0023] The lubricating film layer 2 is composed of an inorganic salt lubricating film 3 directly coated on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com