Automatic assembling technology and device of microwave filter tuning screw

An automatic assembly device and microwave filter technology, applied in assembly machines, metal processing, manufacturing tools, etc., can solve the problems of poor system stability, high price, complex mechanism, etc., and achieve high stability, simple structure, and low efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

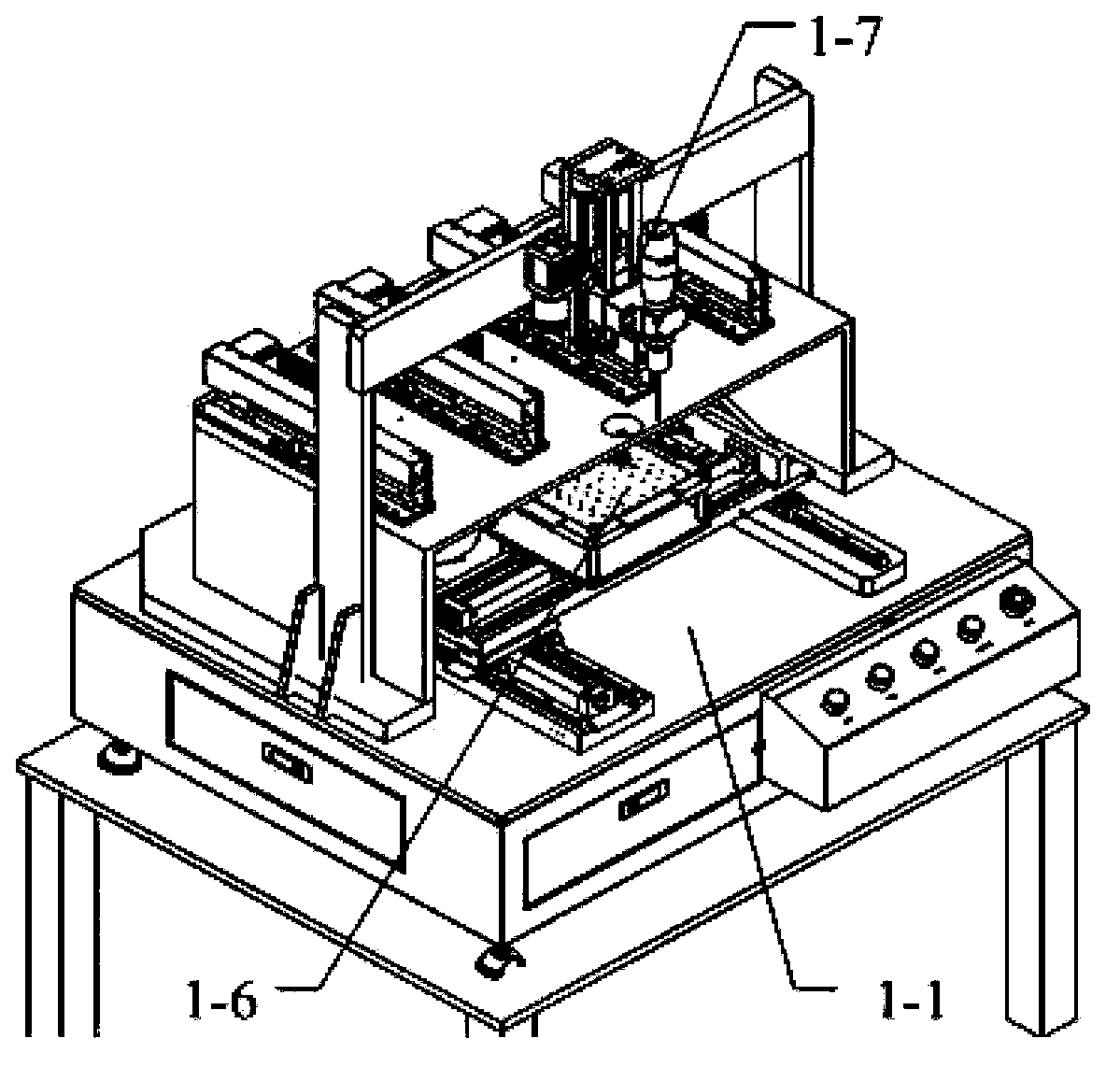

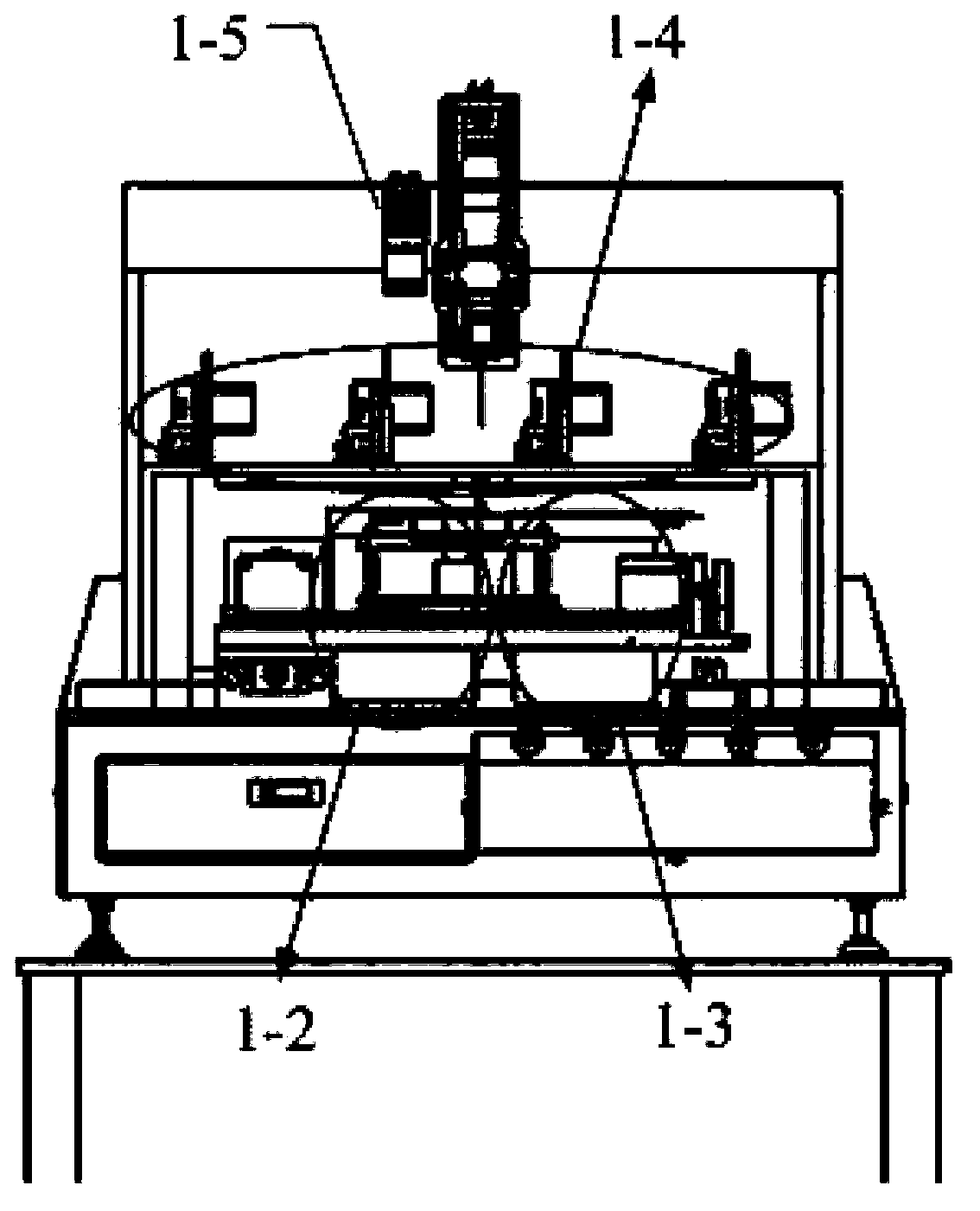

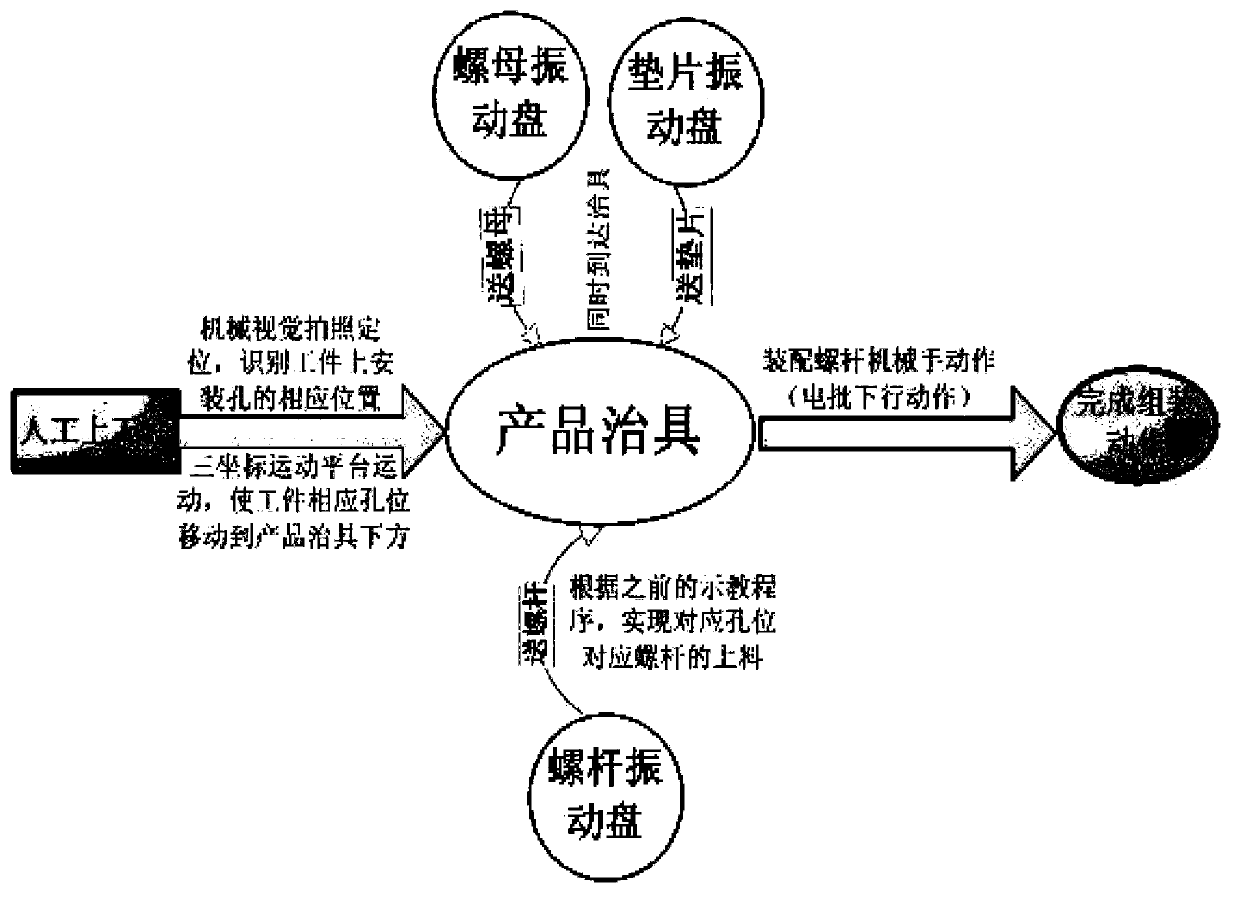

[0051] Accompanying drawing 1 to 9 has provided a specific embodiment of the automatic assembly device of tuning screw rod described in the present invention, and the automatic assembly process that this device adopts comprises the steps:

[0052] Step A: Place the workpiece on a platform module that can move in three-degree-of-freedom rectangular coordinates; the machine vision module recognizes the size and position of the bolt mounting holes of the workpiece, and the platform module drives the workpiece to move so that the mounting holes The bits correspond to the bottom of the product fixture in turn;

[0053] Step B: The gasket feeding module and the nut feeding module complete the feeding action of the gasket and the nut in the product fixture, and the screw feeding module completes the feeding action of the tuning screw corresponding to the installation hole position;

[0054] Step C: Assemble the action of the manipulator module to complete the locking action of the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com