Dry-mixed mortar stirring station and screening and crushing system thereof

A dry-mixed mortar and crushing system technology, which is applied in the field of mixing stations, can solve the problems of waste waste, medium and coarse sand explosive bins, etc., and achieve the effect of easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

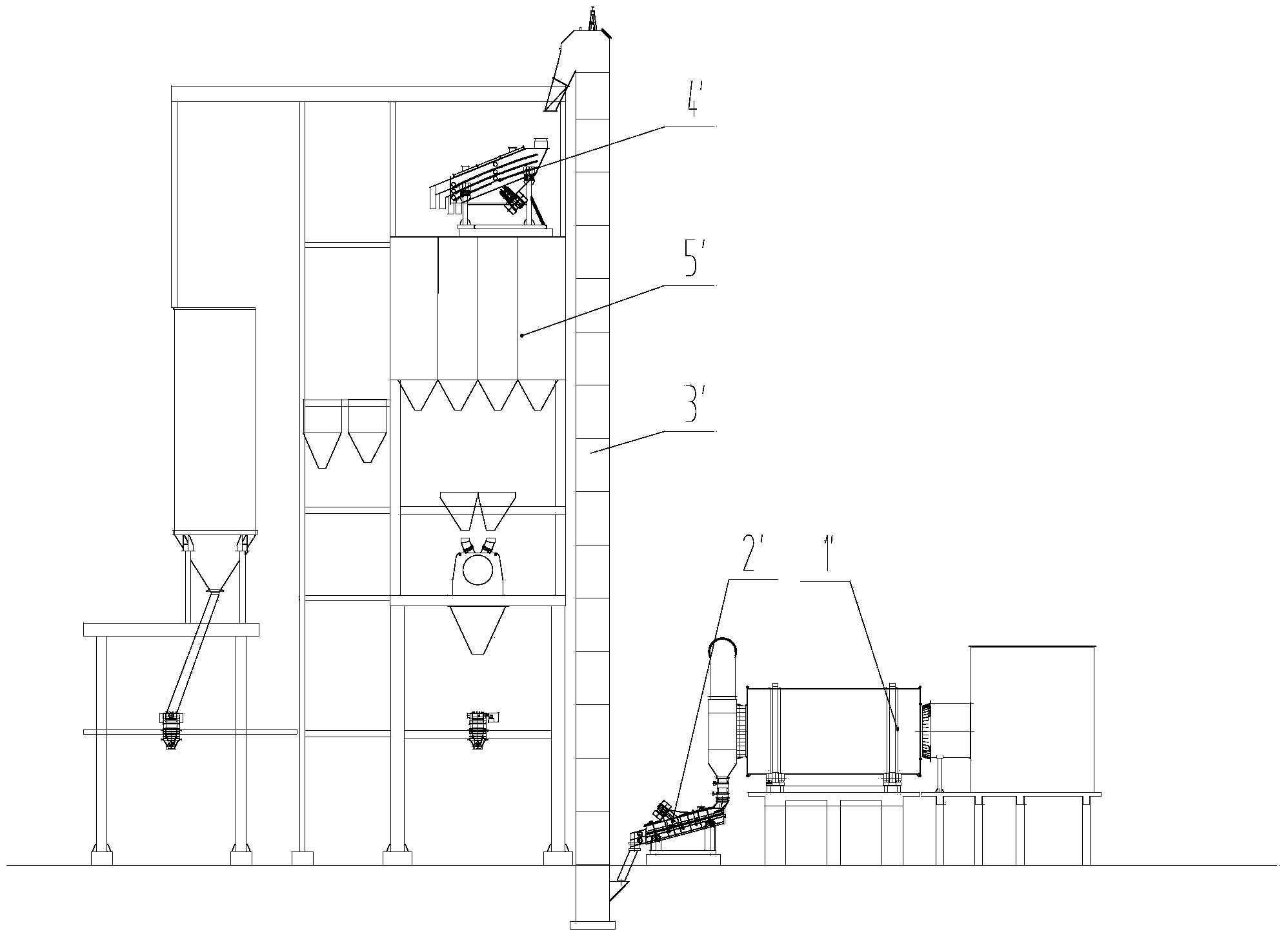

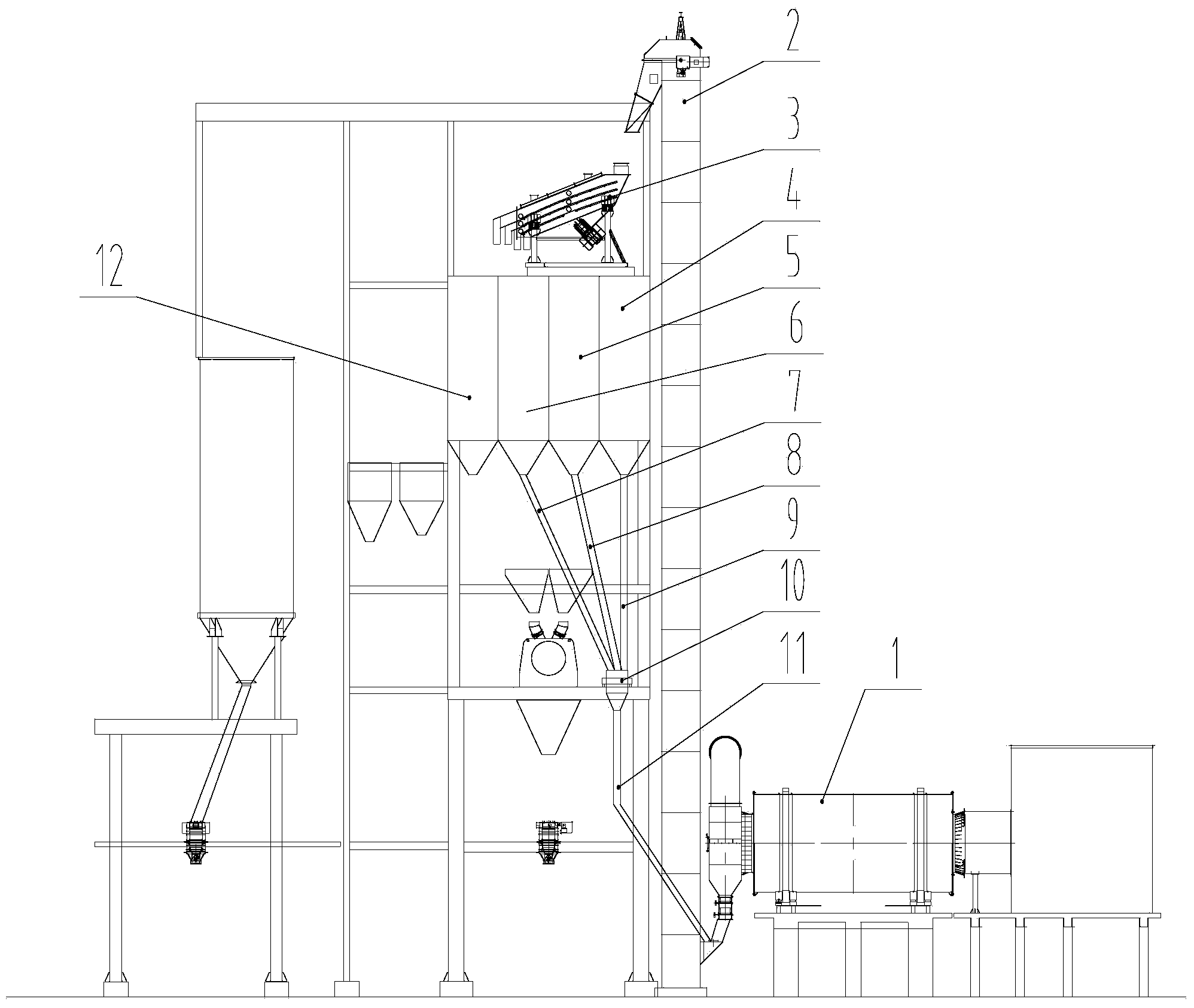

[0021] figure 2 Schematic diagram of the structure of the screening and crushing system of the dry-mixed mortar mixing station provided by the embodiment of the present invention; figure 2 As shown, the screening and crushing system of the dry-mixed mortar mixing plant includes: a dry sand hoist 2, a vibrating screen 3 for receiving the sand output from the dry sand hoist 2, and at least Two storage bins, the first storage bin 12 of at least two storage bins is used to store fine sand, and the second storage bin of at least two storage bins is used to store sand material with a particle size larger than fine sand. The dry-mixed mortar The screening and crushing system of the mixing station al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com