Automatic pipe feeding mechanism of filling production line

A technology of production line and upper tube, applied in packaging and other directions, can solve problems such as production line impact, achieve the effect of reducing equipment cost, improving operation stability and work efficiency, and stabilizing structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

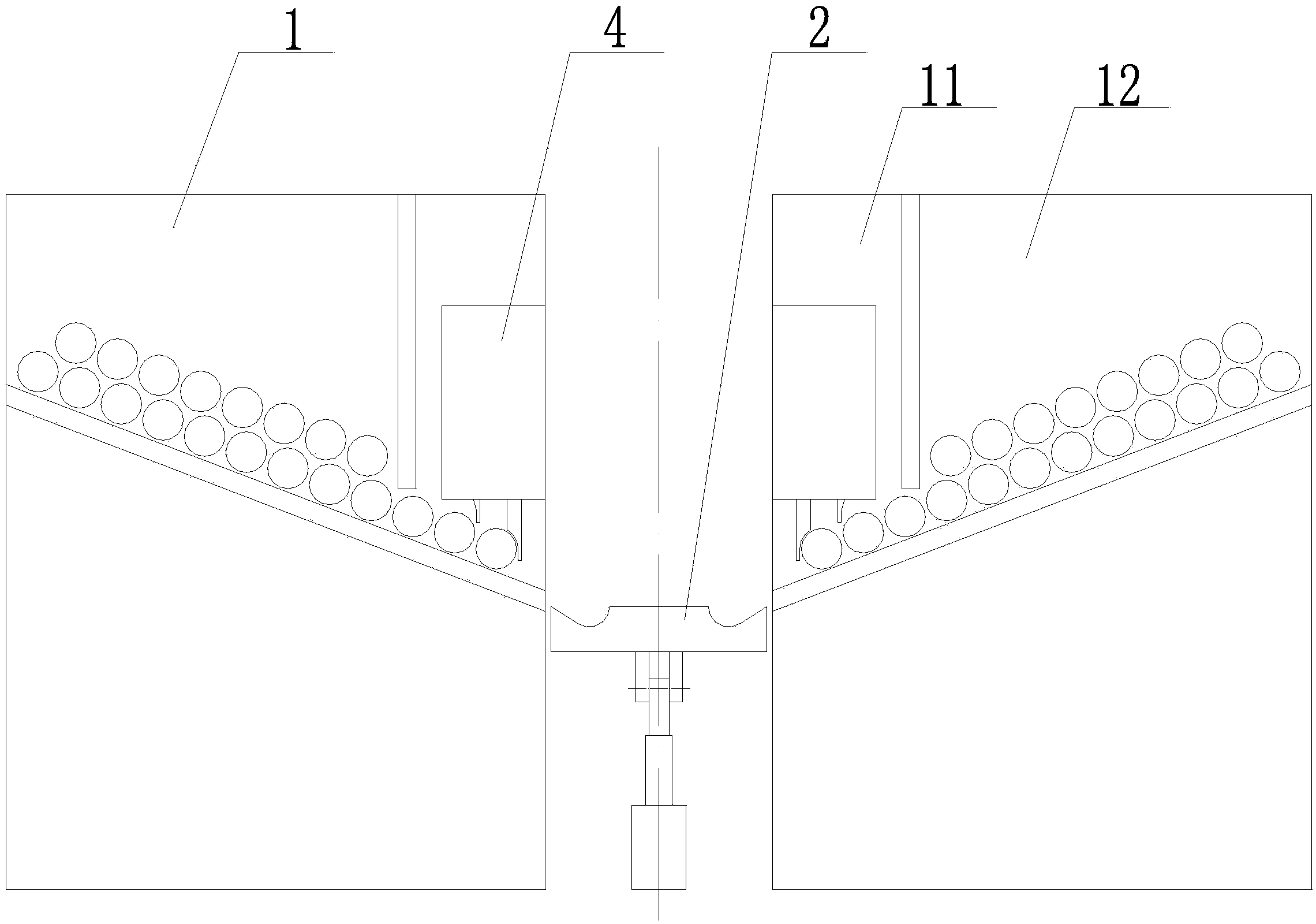

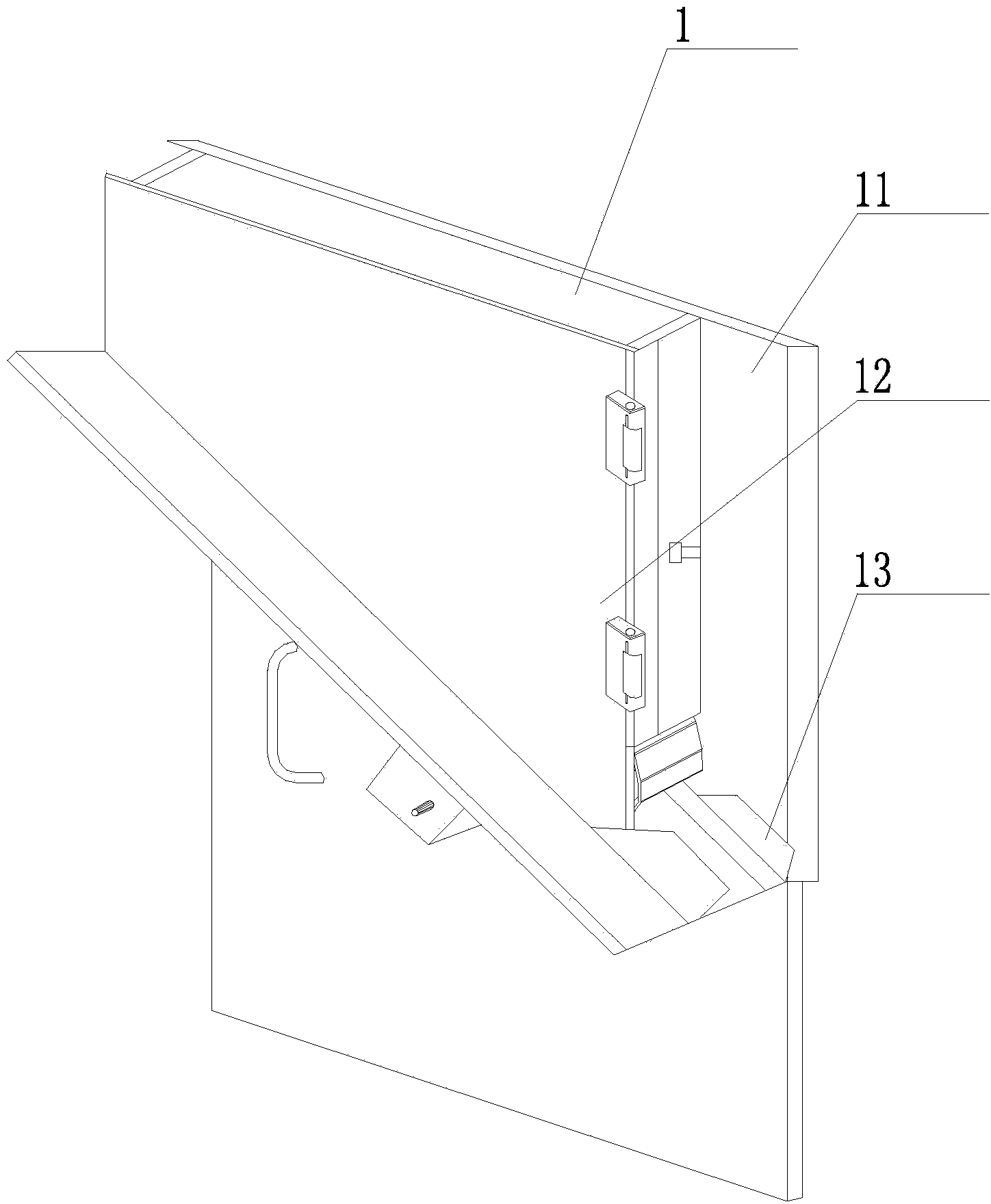

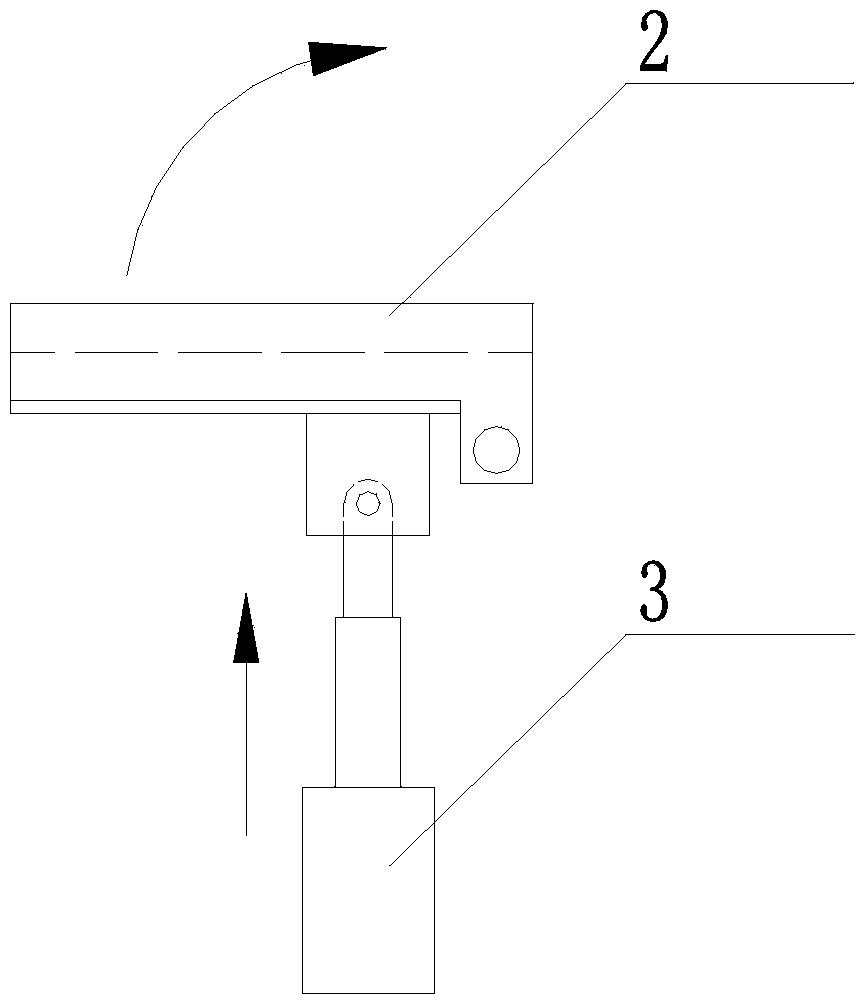

[0040] Example as figure 1 with 5 -7 shows: the quantitative lower tube switch 4 includes a hollow box 41, a vertical baffle 42-1, a vertical baffle 2 43-1, a movable lever 44-1 and a vertical driving device 45-1;

[0041] The first vertical baffle 42-1 is located between the second vertical baffle 43-1 and the flap 2, and the bottom plate of the box body 41 is provided with a The first vertical passage and the second vertical passage adapted to the second vertical baffle 43-1; the upper part of the first vertical baffle 42-1 is provided with a pin one 420-1, and the upper part of the second vertical baffle 43-1 With pin two 430-1;

[0042] The center of the movable lever 44-1 is located between the vertical baffle one 42-1 and the vertical baffle two 43-1, and is hinged on the inner wall of the box body 41, and the movable lever 44-1 A keyway-shaped through hole 1 441-1 for accommodating pin 1 420-1 and a keyway-shaped through hole 2 442-1 for accommodating pin 2 430-1 ar...

Embodiment 2

[0049] Example two such as figure 1 with 8 -12 shows: the quantitative lower tube switch 4 includes a box body 41 with an open bottom, a movable baffle 42-2, a movable baffle 2 43-2, a power disc 45-2, a rotary drive device and several pairs of horizontal Screw rod 44-2; a pair of horizontal screw rods 44-2 are located on the same vertical plane;

[0050] The movable baffle 1 42-2 is located between the movable baffle 2 43-2 and the flap 2, and the movable baffle 1 42-2 is provided with a plurality of sockets socketed on the horizontal screw 44-2. A strip-shaped vertical hole 421-2, the two sides of the vertical hole 421-2 are respectively provided with a number of nuts 423-2 socketed on the horizontal screw rod 44-2; the movable baffle plate 2 43 -2 is provided with a number of elongated vertical holes 431-2 which are socketed on the horizontal screw rod 44-2. Nut II on 433-2;

[0051] The first movable baffle 42-2 is provided with a friction strip 1 422-2 on the end sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com