Assembling type log cabin convex face wall body

A prefabricated, wall technology, applied in the field of buildings, can solve the problems of dull appearance, easy ventilation, unstable wall, etc., and achieve the effect of good wind and rain resistance, beautiful appearance, and stable wall.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

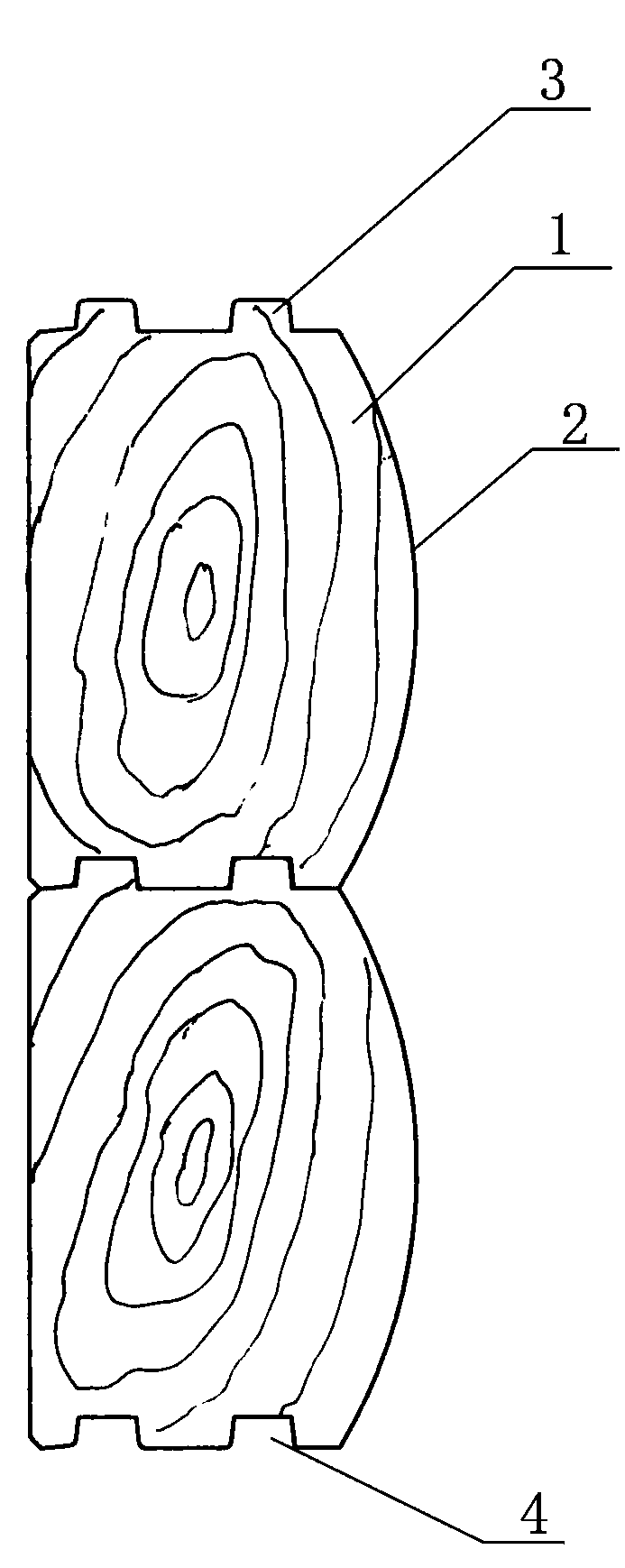

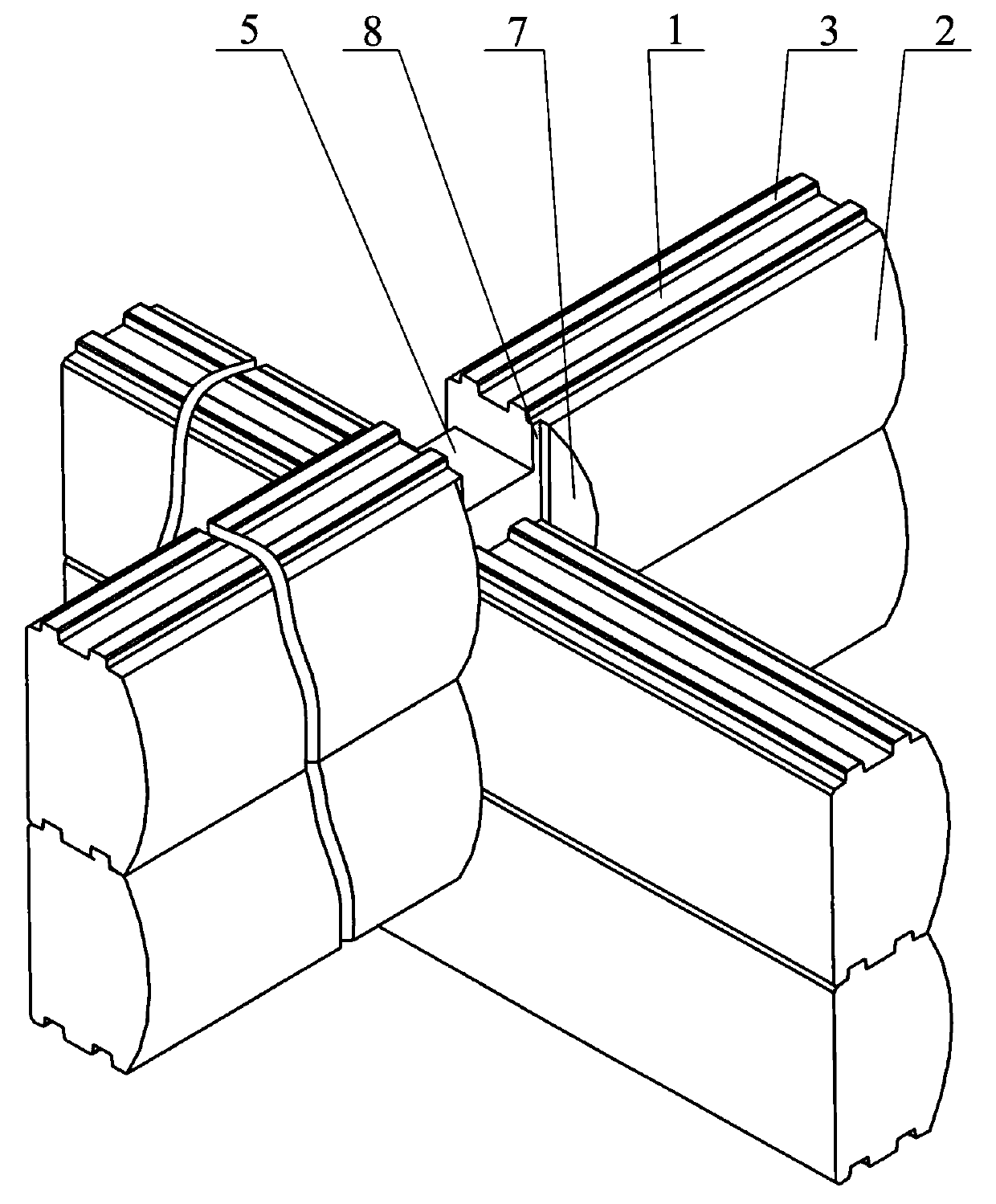

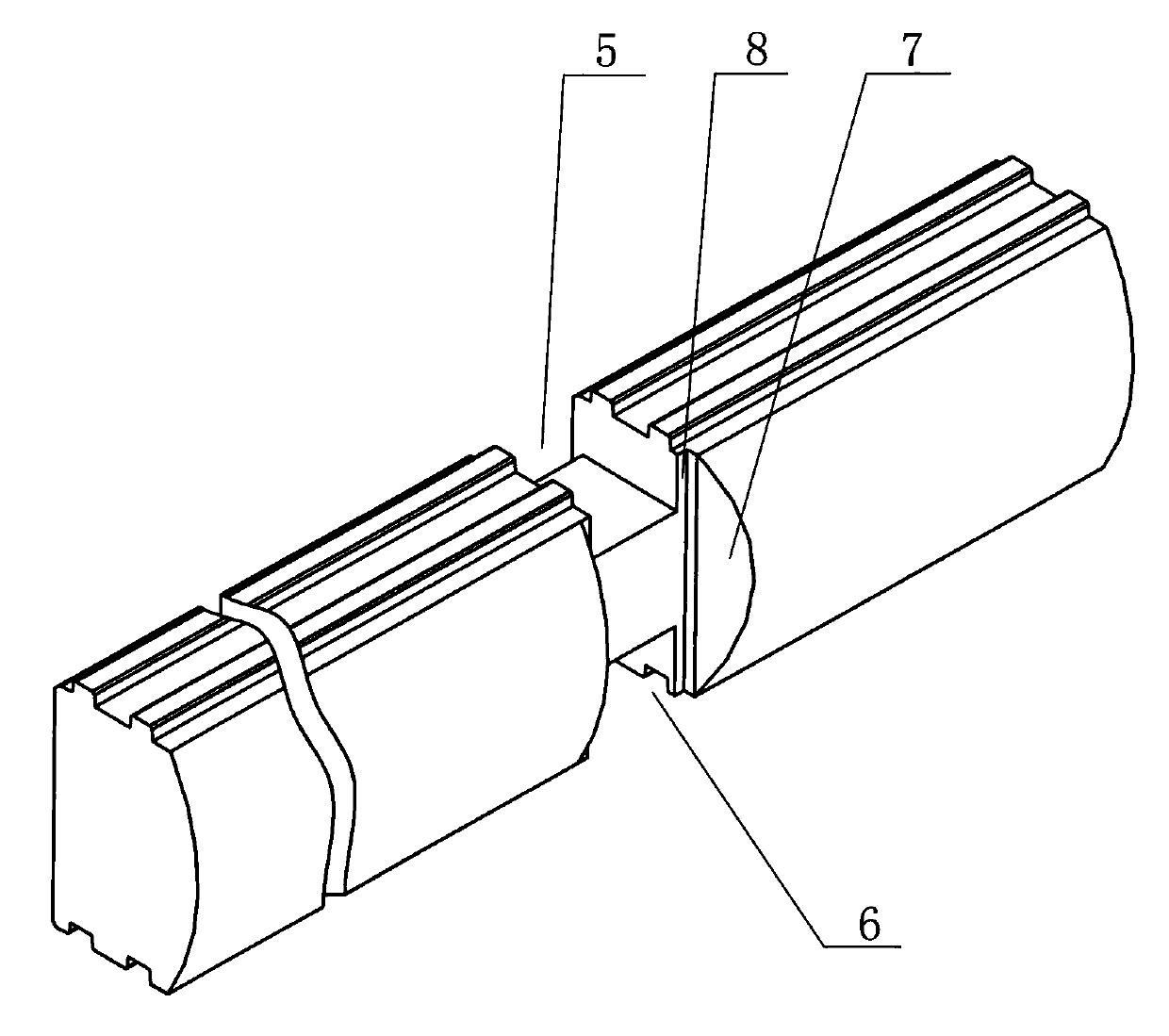

[0016] exist figure 1 and figure 2 In the schematic diagram of the convex wall of the prefabricated wooden house shown, the wooden profile 1 of the wall of the present invention has a rectangular parallelepiped base, and the side surface of which is used as the outer wall is provided with a middle part that is integrated with it. The section is approximately D-shaped, and the section of the raised part of the outer wall is arc 2 . The mortise and tenon on the wall profile of the present invention is a double mortise, that is, the top surface of the wall profile is provided with the same two upwardly protruding tenons 3, and the bottom surface is provided with two mortise 4 corresponding to the two tenons on the top surface , they are all symmetrical about the vertical centerline of the section of the profile (the convex part is not included). The section of the tenon is an isosceles trapezoid, the depth of the groove sandwiched between the two tenons is greater than the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com