Roofing foam cement rigid heat insulation system

An insulation system and foamed cement technology, applied in the direction of roof covering layer, building roof, roof insulation material, etc., can solve the problems of insufficient roof strength, unfavorable energy saving and environmental protection, lack of thermal insulation structure, etc., and achieve the effect of ensuring rigid strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

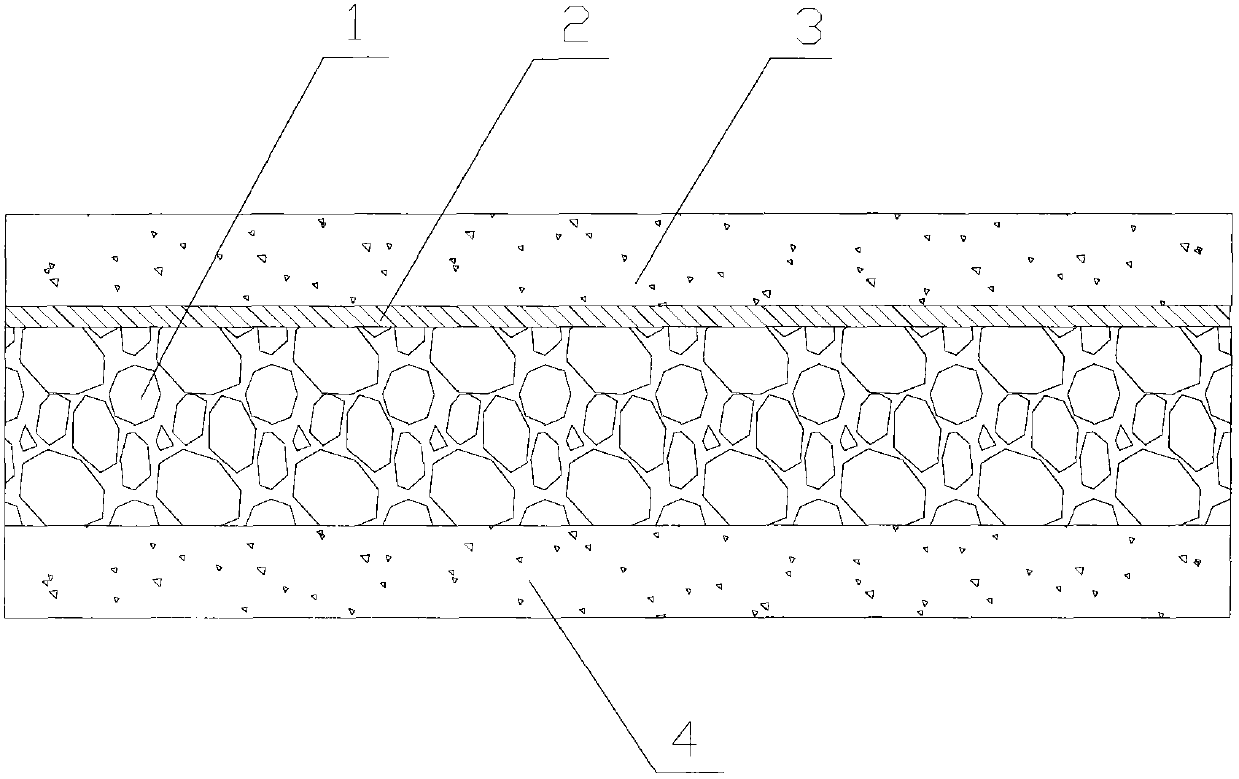

[0011] see figure 1 , a roof foam cement rigid insulation system related to the present invention, the system includes a foam cement layer 1, the bottom surface of the foam cement layer 1 is provided with a bonding layer 4, the foam cement layer 1 A steel bar layer 2 is arranged on the top surface of the steel bar, and a concrete layer 3 is coated on the steel bar layer 2 .

[0012] When in use, the foamed cement layer 1 of the roof foamed cement rigid insulation system is firmly bonded to the roof through the bonding layer 4, thereby realizing the heat preservation effect; The concrete layer 3 is poured on the reinforcement layer 2, thereby improving the rigidity of the roof.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com