Archaized floor and manufacturing method thereof

A technology of antique floor and surface board, applied in the field of decorative materials, which can solve the problems of imperfect antique effect of the floor and loss of style floor, etc., and achieve the effect of mature manufacturing process, strong three-dimensional effect and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

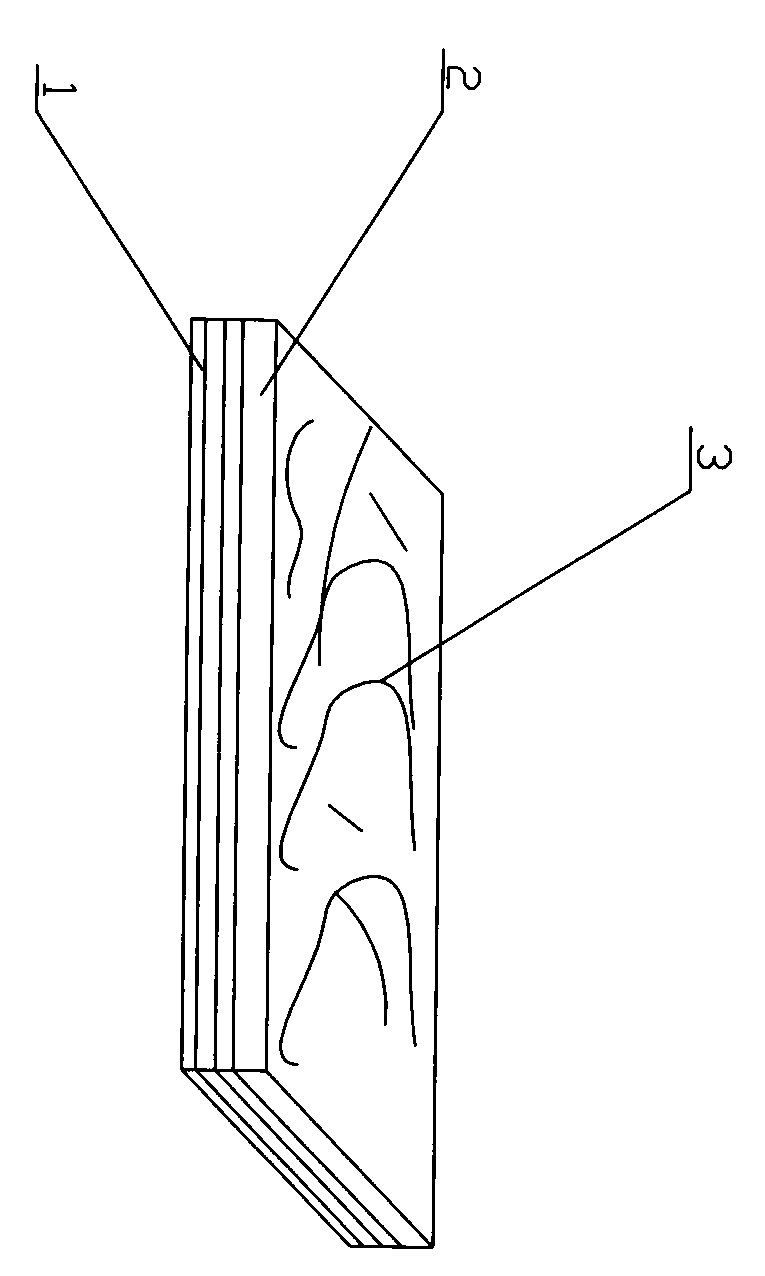

[0018] Embodiment 1 A kind of antique floor, as shown in Figure 1, base plate 1 and surface plate 2, described base plate and surface plate are bonded together, and surface plate is provided with paint layer; The top surface of described surface plate There are irregularly arranged scratches 3 on it, and the scratches are scratched and polished by hand.

Embodiment 2

[0019] Embodiment 2 A kind of preparation method of antique floor, the steps are as follows:

[0020] (1) Material selection: Take the entire base plate blank and surface plate blank, and the blanks are purchased from Dalian Penghong Wood Industry Co., Ltd. to ensure that the base plate blank and the surface plate blank are not damaged;

[0021] (2) Planing: planing the substrate board blank and the surface board blank using a planer;

[0022] (3) Slicing: The planed base plate blank and surface plate blank are cut into several base plate and surface plate according to the required size, and the cutting is completed by a frame saw machine;

[0023] (4) Drying balance: Put the sliced base plate and surface plate into the drying room, and dry at 45°C for 3 days;

[0024] (5) Pressing: apply glue on the dried base plate, the glue is Japanese Dalu floor glue, the surface plate is pasted on the base plate, and then the base plate and the surface plate are pressed together by a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com