Multilayer gentle dip thin-medium ore deposit filling and mining method

A technology of backfill mining and gentle inclination, applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of long construction period of mining and cutting engineering, complex production connection management, poor continuity of mining, etc., and reduce mining and cutting roadway excavation. The effect of increasing the production capacity of the mine and reducing the dilution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

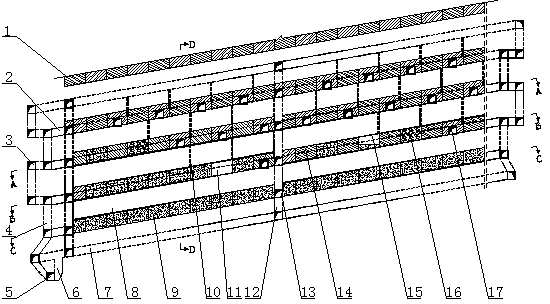

[0033] The invention relates to a filling mining method for a multi-layer gently inclined thin-medium-thick ore deposit. The multi-layered ore bodies of this deposit are produced in layers or parallel layers, the ore body dip angle is 5~25°, the ore body length is generally 224~670m, the dip depth is 87~204m, and the ore layer thickness is generally 0.81~5.54 m, the thickness of interlayer stone layer is 5~12m. The rock stability of this deposit is relatively good, and the engineering geological conditions of the mining area are of simple-medium type.

[0034] The concrete steps of this ore deposit filling mining method are:

[0035] 1) Block division and mining and cutting engineering layout

[0036] ① Block division

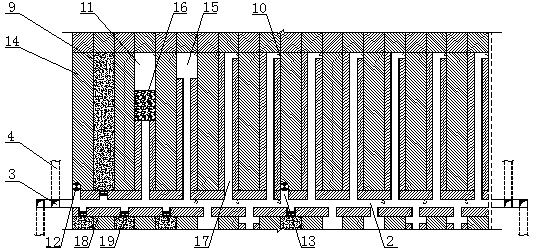

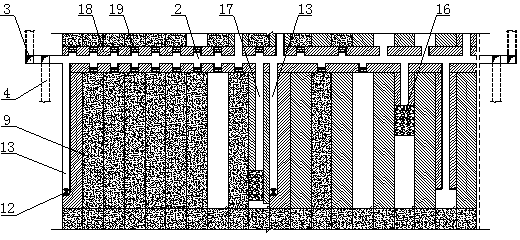

[0037] Divide the deposit into stages such as figure 1 with figure 2 As shown, each layered ore body in the stage is divided into panels. Drill uphill 2 at the bottom of ore layer 1 along the orebody tendency, divide the orebodies on both sides into mine...

Embodiment 2

[0049] The invention relates to a filling mining method for a multi-layer gently inclined thin-medium-thick ore deposit. The ore deposit is a horizontal to gently inclined multi-layer thin deposit, with an orebody dip angle of 0~18°, a strike length of 620~1100m, and a dip extension of 460~856m. 6~10m, the ore rock stability of this deposit is moderate to good, and the engineering geological conditions of the mining area are of simple-medium type.

[0050] This ore deposit filling mining method is the same as embodiment 1.

[0051] Compared with the prior art, this specific embodiment has the following positive effects:

[0052] In this specific embodiment, each layered ore body is divided into panels, and the mine houses 15 and ore pillars 14 are arranged in a staggered manner, so that multiple panels and multiple stopes can be mined simultaneously. At the same time, the mining and filling of different stopes in the panel can work in parallel without interfering with each o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com