Flexible wind generating set transmission system

A technology for wind turbines and transmission systems, applied in wind turbine components, wind turbines, wind power generation, etc., can solve the problems of bad stress on the main shaft bearing, no buffering, and unstable transmission, so as to reduce design costs and reduce The effect of load and transmission is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

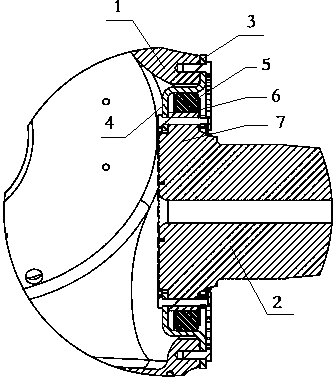

[0012] The transmission system of a flexible wind power generating set of the present invention is designed to reduce the impact from the impeller and reduce the ultimate load borne by the main shaft 2 bearings. The present invention adds a transmission damping device at the joint between the impeller and the main shaft 2 of the transmission system of the traditional wind power generating set. The hub is connected to the main shaft 2 through a transmission and damping device to transmit torque. This device has the function of not reducing the transmission torque and reducing the overturning moment.

[0013] The specific structure is as figure 1 Shown, the present invention comprises impeller and main shaft 2, and main shaft 2 front end stretches into impeller

[0014] In the hub of the impeller, the hub 1 of the impeller is provided with a ring-shaped elastic buffer disk set on the main shaft 2. The disk surface of the elastic buffer disk is a stepped shape transitioning from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com