Large-flexibility rotary hinge with annularly and uniformly distributed semi-ring sheets

A kind of circularly distributed, rotating hinge technology, applied in the direction of pivot connection, etc., can solve the problems of small rotation angle, stress concentration application range, insufficient effect, difficult processing, etc., and achieve the effect of increasing rotational stiffness, convenient processing, and reducing drift.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

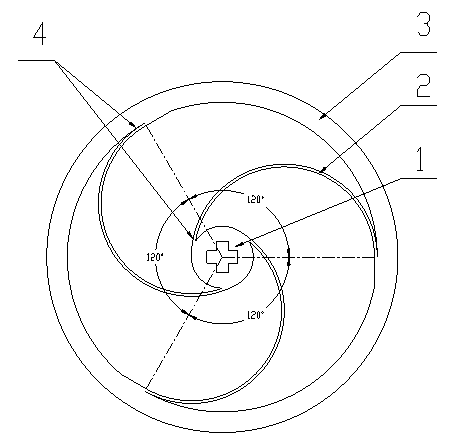

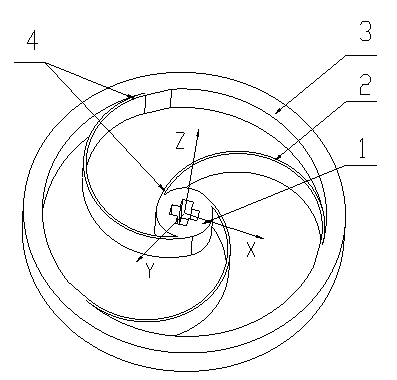

[0025] like figure 1 and figure 2 shown in figure 1 Among them, the two ends of the three semi-circular spring pieces 2 are inscribed with the input and output part 1 and the fixed part 3 and connected to the inscribed connection part 4, specifically, the outer diameter surface of the spring piece 2 is tangent to the outer surface of the input and output part 1, The inner diameter surface of the spring sheet 2 is tangent to the inner surface of the fixed part 3; The structure of the input and output part 1 and the fixing part 3 may be determined according to the circumstances. The inner diameter, outer diameter and width of each leaf spring 2 are consistent, so that the stability of the output can be ensured, that is, the output of the corner can be obtained while the offset of the input and output parts can be reduced as much as possible. exist figure 2 Among them, the included angles between adjacent spring pieces 2 are all 120°, that is, they are uniformly distributed...

Embodiment 2

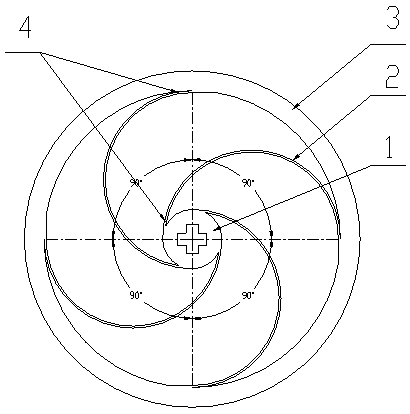

[0029] The difference between embodiment 2 and embodiment 1 is that: the two ends of the four semi-circular spring pieces 2 evenly distributed are respectively inscribed with the input and output part 1 and the fixed part 3 and connected to the inscribed connection part 4, that is, each adjacent spring piece The angle between 2 is 90° respectively.

Embodiment 3

[0031] The difference between embodiment 3 and embodiment 1 is that: the two ends of the evenly distributed five semi-circular spring pieces 2 are respectively inscribed with the input and output part 1 and the fixed part 3 and connected to the inscribed connection part 4, that is, each adjacent spring piece The angle between 2 is 72° respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com