Deep hole temperature measurement device

A temperature measuring device and deep hole technology, applied in measuring devices, thermometers, measuring heat, etc., can solve the problem of not being able to measure the temperature of the deep hole in real time in the operating state, so as to prevent accidents, ensure safety, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

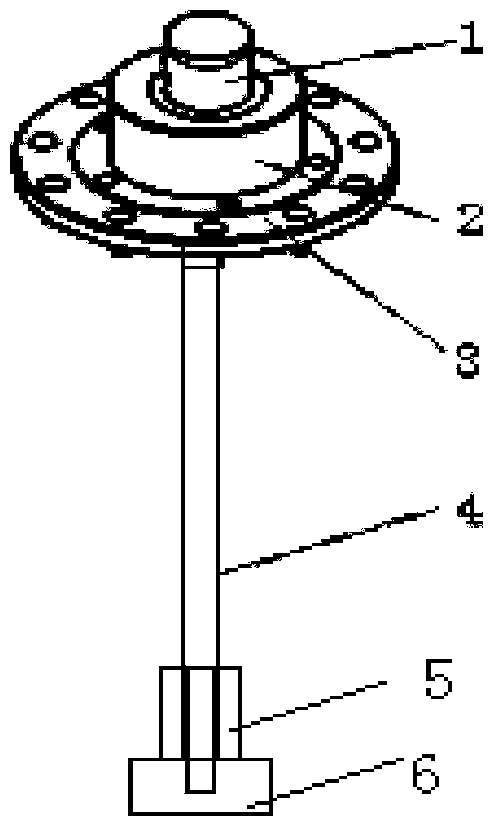

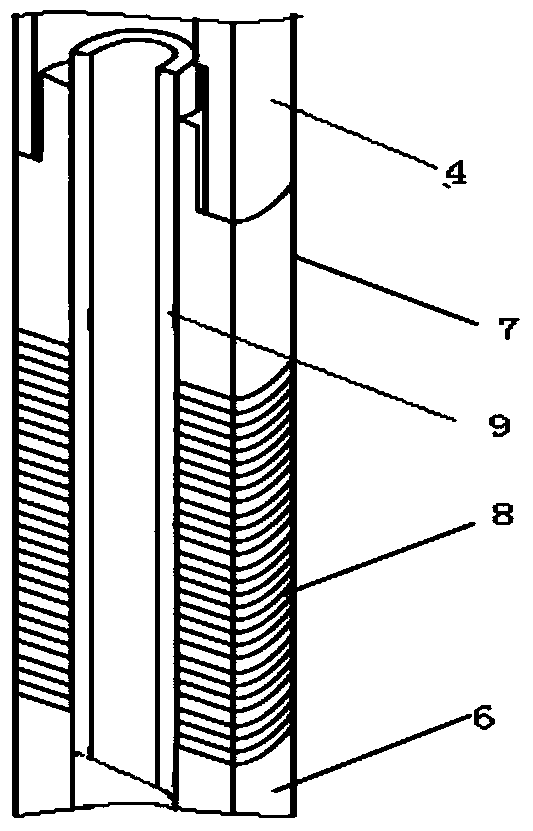

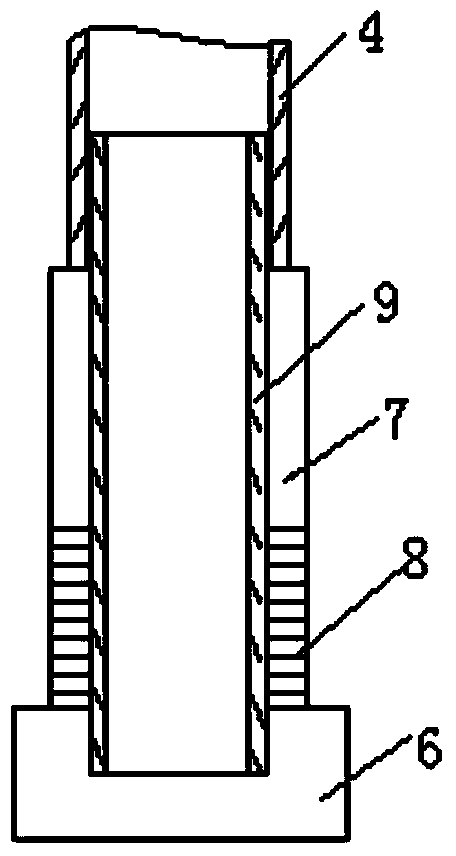

[0023] This embodiment is a deep hole temperature measuring device used in the production process of energetic materials, including a protective cover 1, a conductive slip ring 2, a bearing outer ring flange 3, a signal line packaging tube 4, a temperature sensor 6 and a sensor Pressure mechanism 5. The temperature sensor 6 is installed at the bottom of the shaft center hole of the blade, and is attached to the hole wall through the pressure of the sensor pressing mechanism 5 . The wires of the temperature sensor 6 are connected to the conductive slip ring 2 through the signal line packaging tube 4, and then lead to the control room through the conductive slip ring 2.

[0024] The conductive slip ring 2 includes a protective cover 1, a connecting ring 19, a bearing outer ring flange 3, a support seat 12, a connecting block 20, a connecting base 21, a sensor connecting seat 22, a bearing outer ring gland 11, and a pressure adjustment nut 10. Conductive slip ring inner ring 16,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com