A kind of cold spraying device and method for preparing 316l stainless steel coating

A cold spraying, stainless steel technology, applied in pressure inorganic powder coating and other directions, can solve problems such as poor coating quality, and achieve the effect of saving process, promoting gas expansion and tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

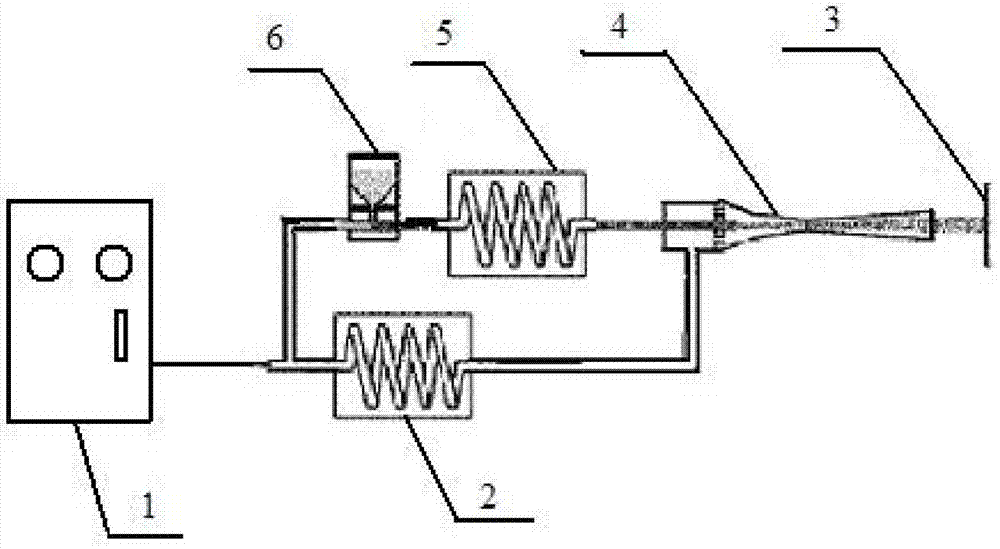

Method used

Image

Examples

Embodiment 1

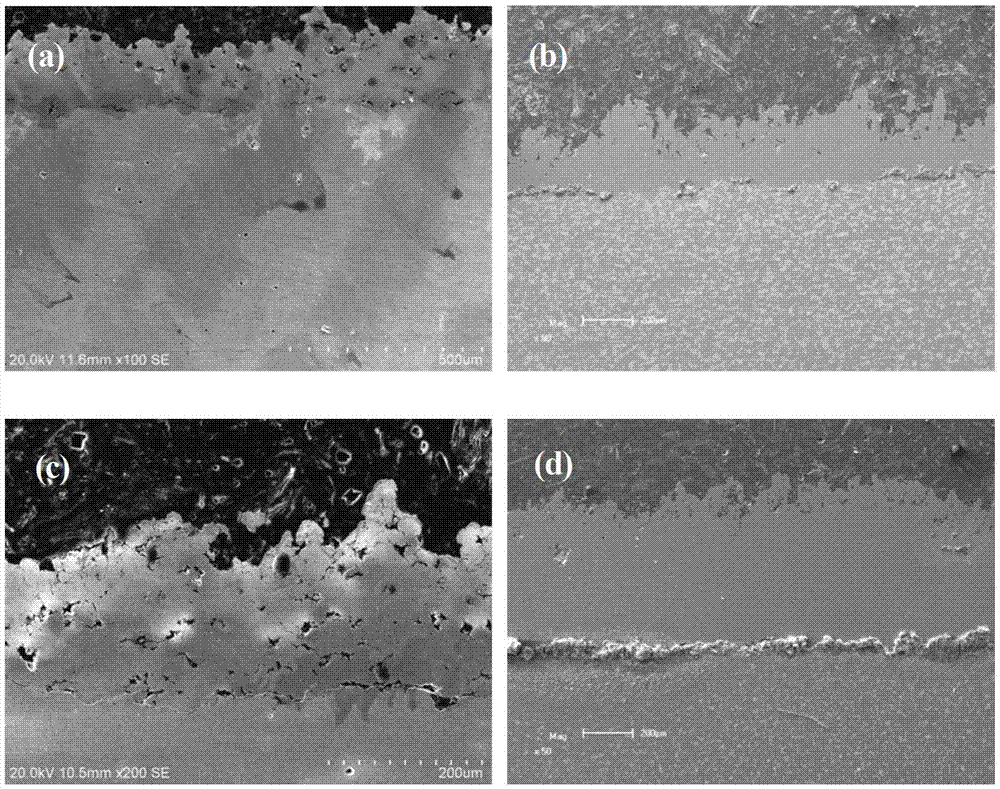

[0031] The 316L stainless steel coating is prepared by using the cold spraying equipment added with the powder feeding heater of the present invention, the spraying material is 316L stainless steel powder of -400~-500 mesh, and the spraying base material is 45# steel. The specific process parameters are: the carrier gas pressure is 2.0MPa, the carrier gas heating temperature is 500°C, the powder feeding heating temperature is 470°C, and the spraying distance is 20mm.

[0032] The SEM photo of the interface between the prepared cold sprayed stainless steel coating and the substrate is as follows: figure 2 (b) shown.

Embodiment 2

[0037] The difference from Example 1 is that the carrier gas heating temperature is 550°C, and the SEM photo of the interface between the prepared cold sprayed stainless steel coating and the substrate is as follows: figure 2 (d) shown.

Embodiment 3

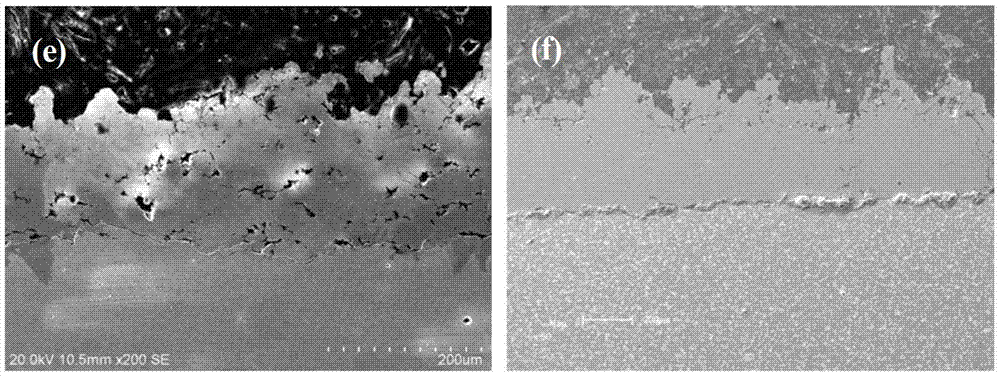

[0041] The difference from Example 1 is that the carrier gas heating temperature is 600°C, and the SEM photo of the interface between the prepared cold sprayed stainless steel coating and the substrate is as follows: figure 2 (f) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com