Lens drive device, auto-focusing camera and mobile terminal device with camera

A lens driving device and lens technology, which is applied to cameras, focusing devices, electromechanical devices, etc., can solve the problems of spring characteristic deviation of elastic support body and difficulty of spring elastic support body, so as to reduce characteristic deviation and small deviation of spring characteristic Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

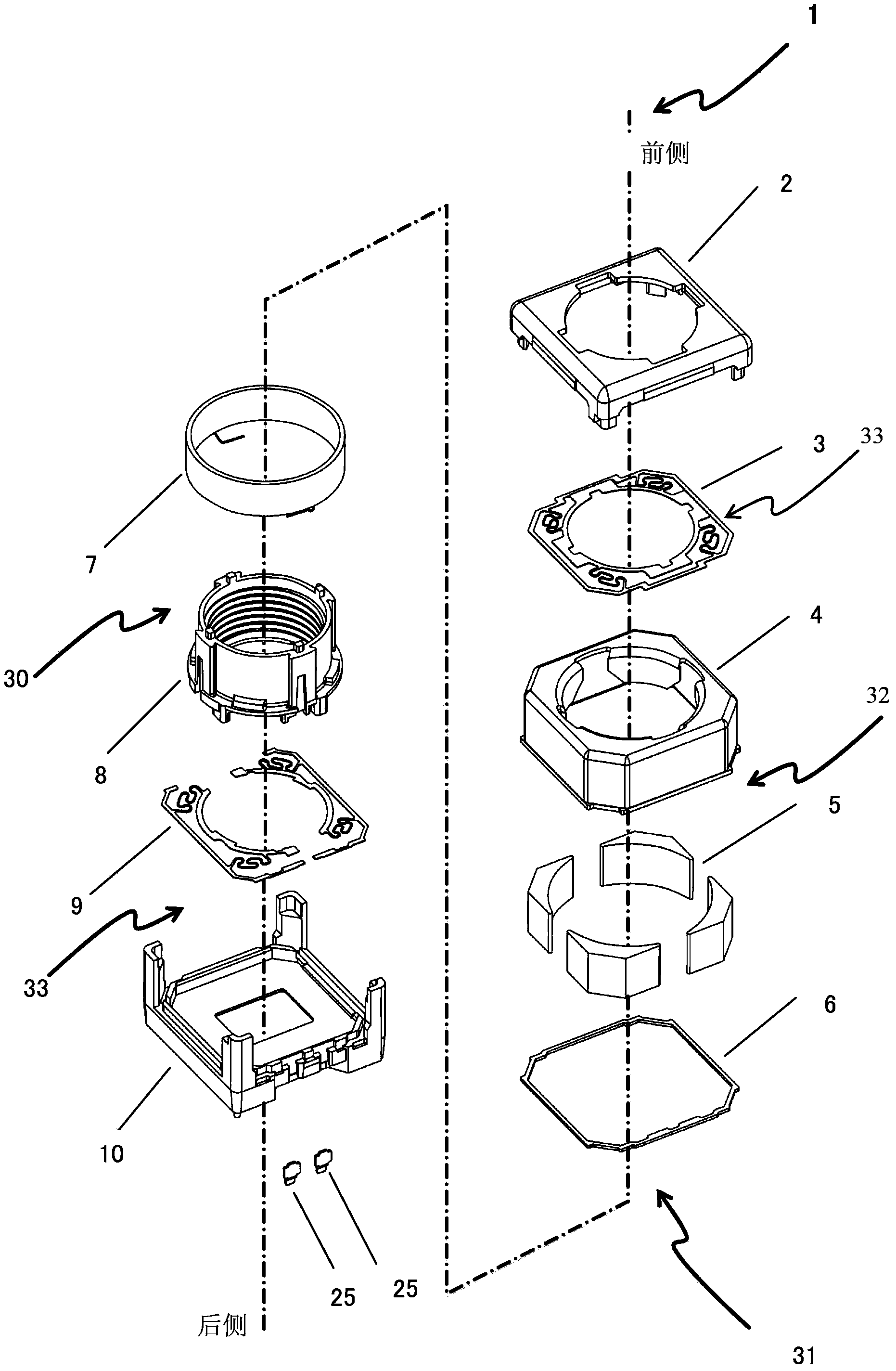

[0048] Embodiments of the present invention will be described below with reference to the drawings. The lens driving device 1 in the embodiment of the present invention is a device built in a mobile phone or the like and mounted on an autofocus camera device.

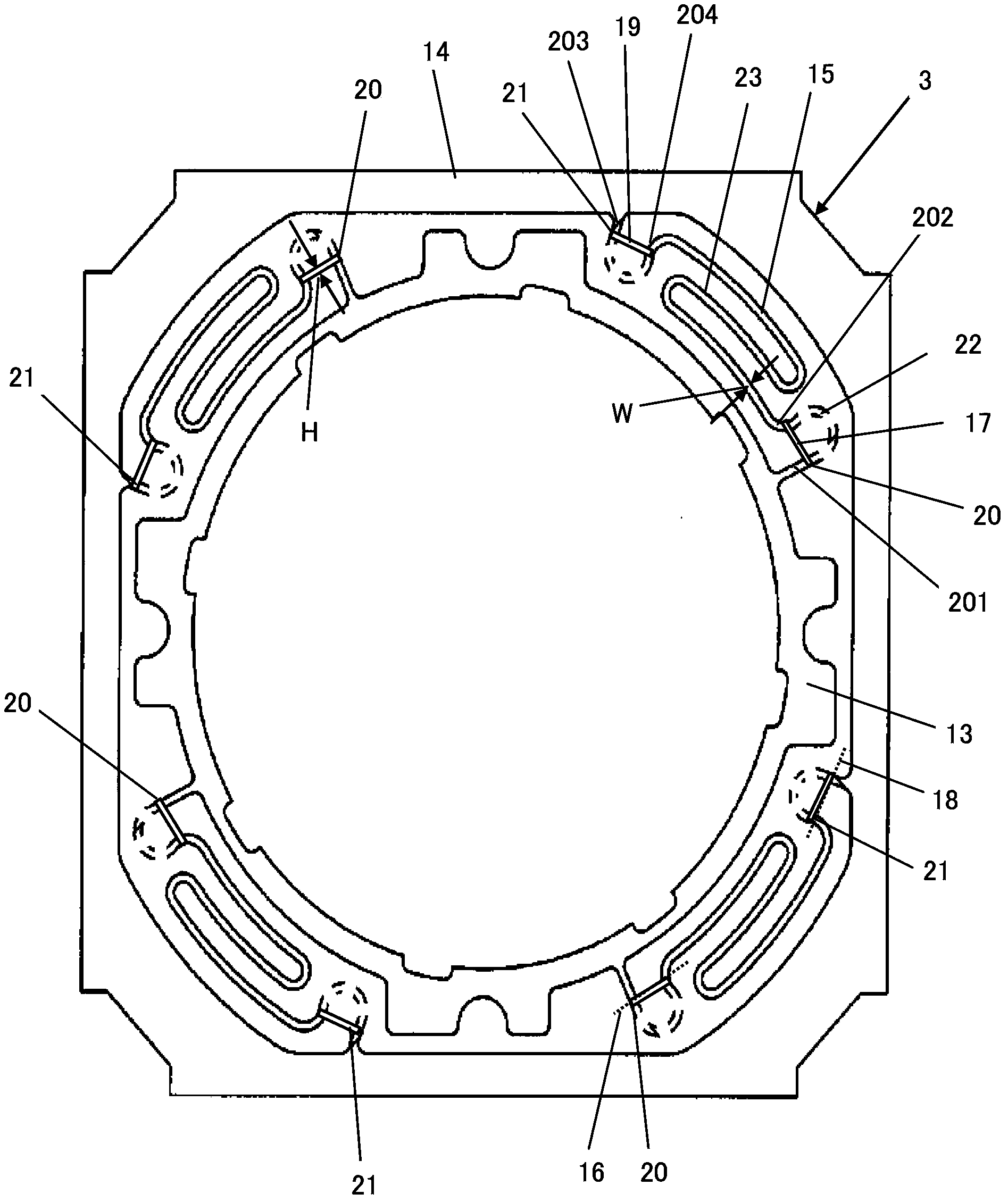

[0049] Such as figure 2 As shown, the lens driving device 1 includes: a moving body 30 having a lens holder 8 serving as a holding portion holding a lens (not shown) in the center; and a fixed body 31 housing the moving body 30 on the inner peripheral side. The movable body 30 is composed of a lens holder 8 and a drive coil 7 wound around the outer peripheral side of the lens holder 8 . The fixed body 31 is composed of the frame 2 , the collar 4 , the magnet 5 , the rear gasket 6 , and the base 10 .

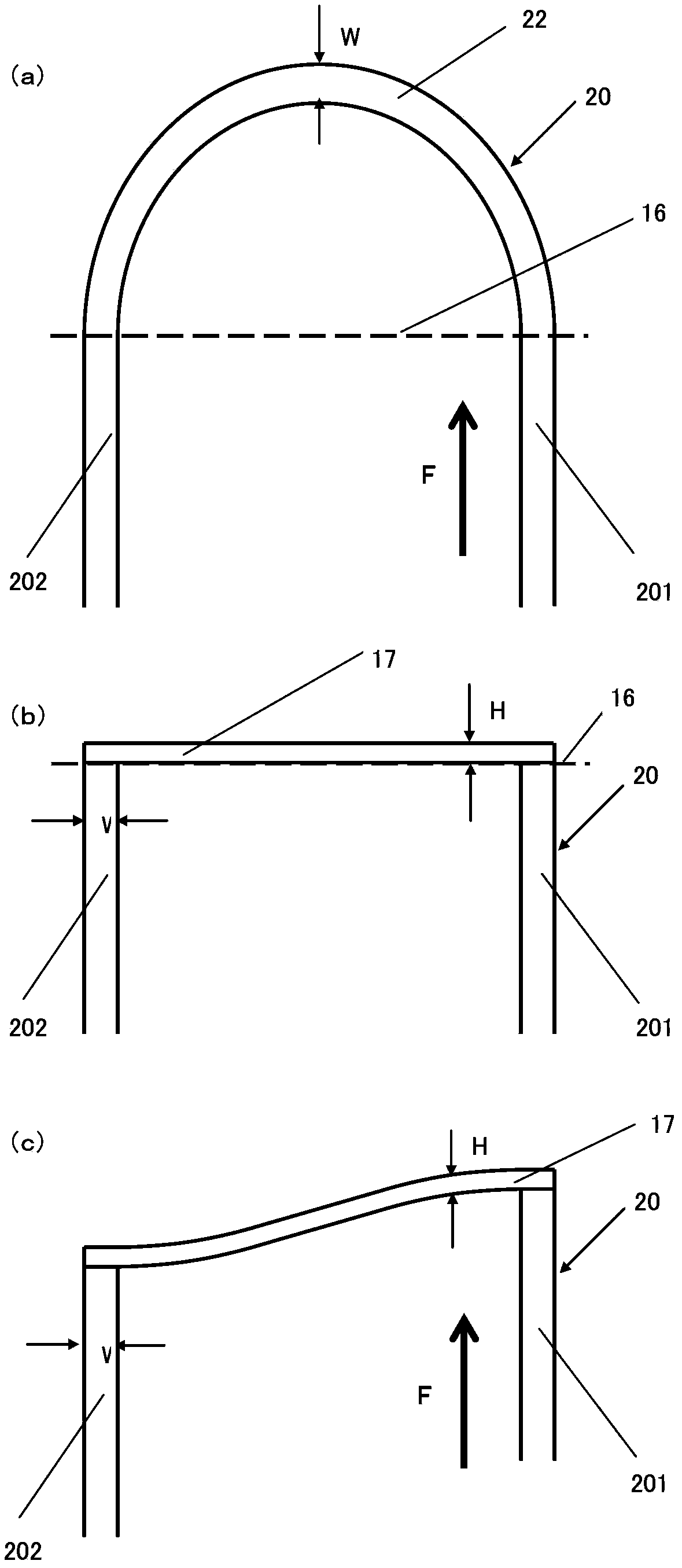

[0050] In addition, the lens driving device 1 includes a driving unit 32 belonging to at least one of the movable body 30 or the fixed body 31 that generates a driving force to move the movable body 30 relative to the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com