Pole piece movement clipping method and assembly of lithium battery cell processing equipment

A processing equipment, lithium battery technology, applied in electrode manufacturing, electrical components, secondary batteries, etc., can solve problems such as low efficiency of cutting pole pieces, and achieve the effect of improving production efficiency, improving work efficiency, and solving low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

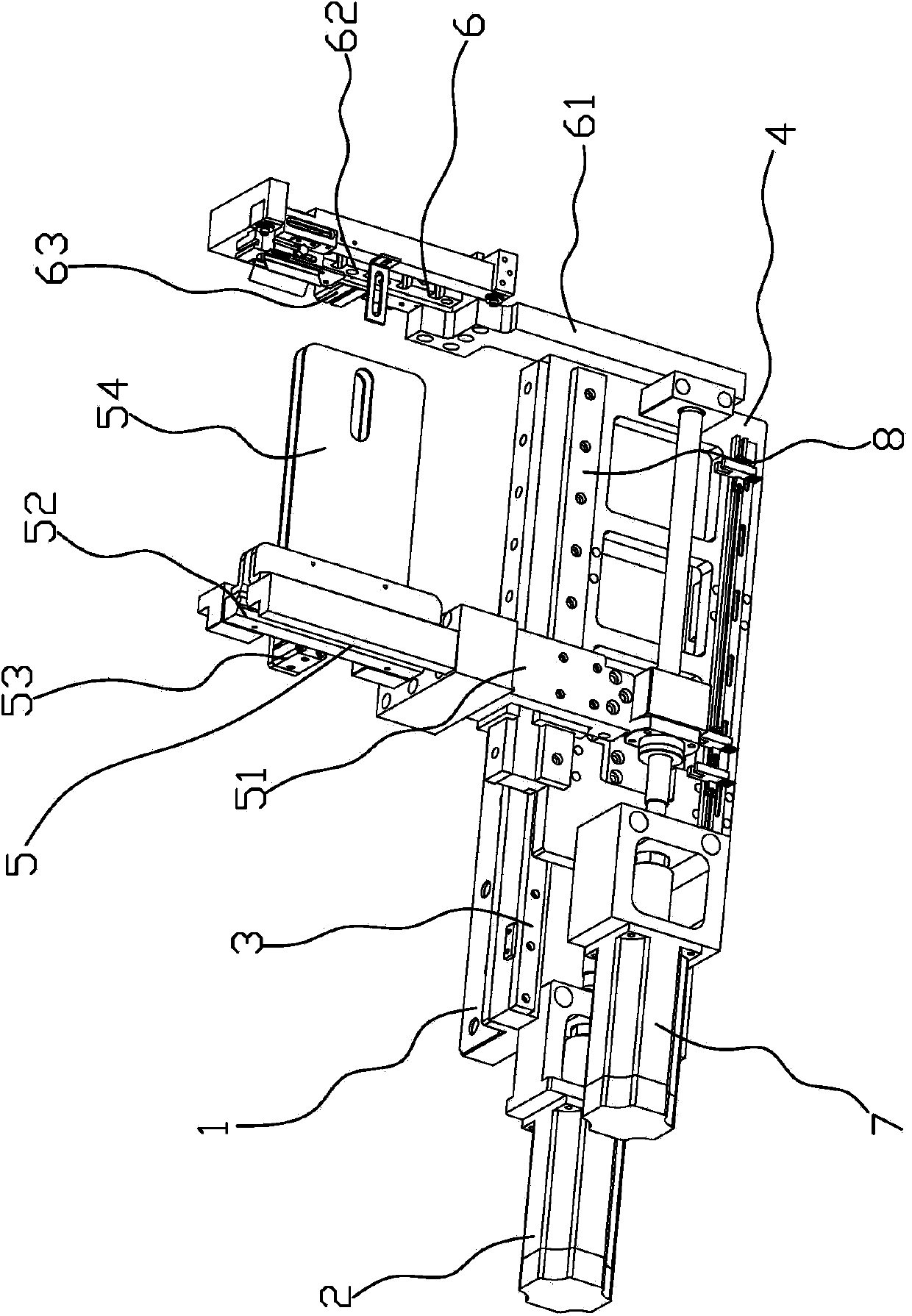

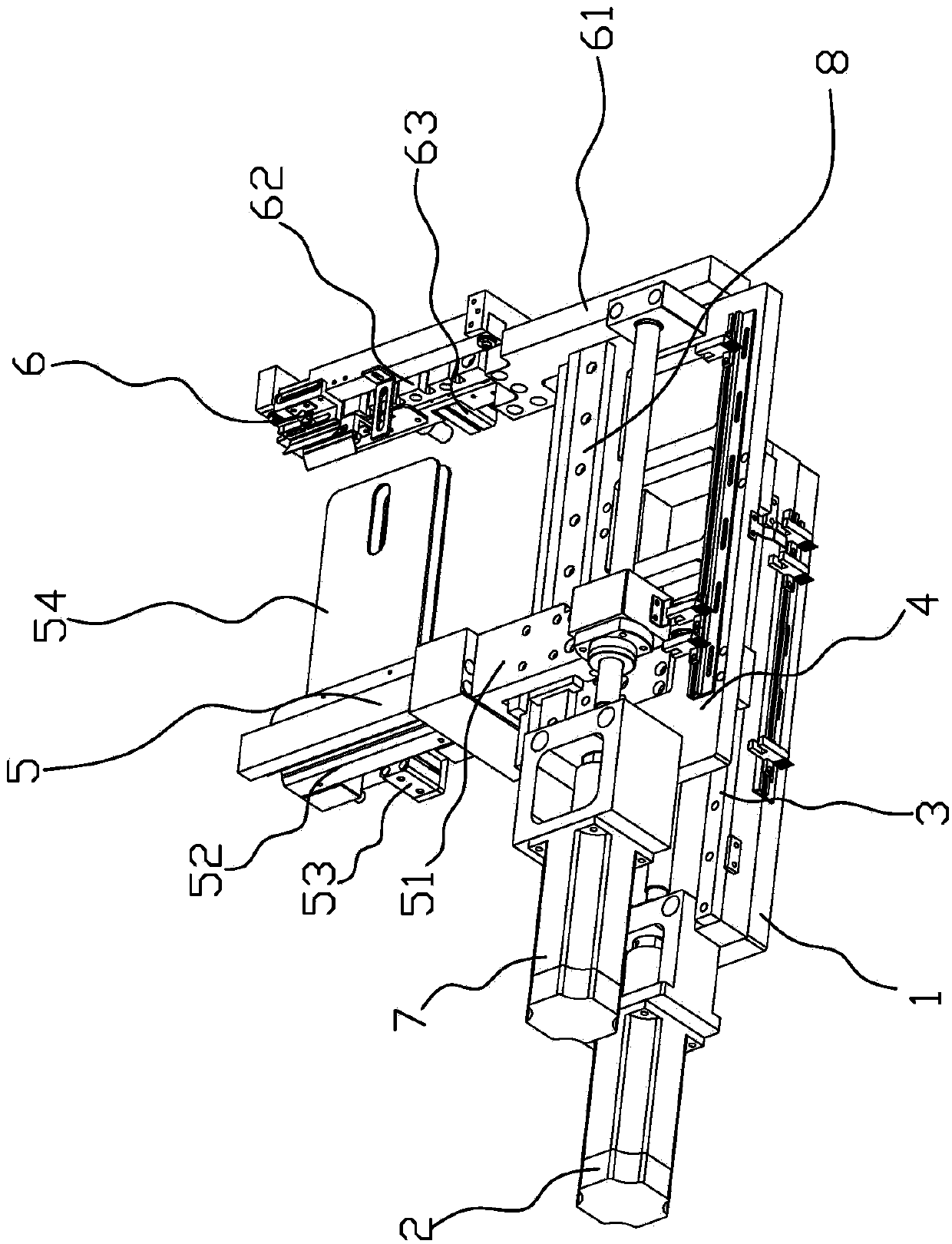

[0016] A method for cutting the pole piece movement of lithium battery cell processing equipment. First, use a diaphragm encoder to read the diaphragm information when the device is wound on the battery cell. When the diaphragm is wound to a preset length, the diaphragm encoder outputs a signal to drive The pole piece clamping mechanism clamps the pole piece and moves at the same speed and the same direction as the pole piece. At the same time, the pole piece cutting mechanism moves at the same speed and the same direction as the pole piece. After the pole piece is clamped by the pole piece clamping mechanism, the pole piece is cut off. The mechanism cuts the pole piece. After the pole piece is cut, the pole piece clamping mechanism and the pole piece cutting mechanism are reset, and the pole piece cutting process is completed.

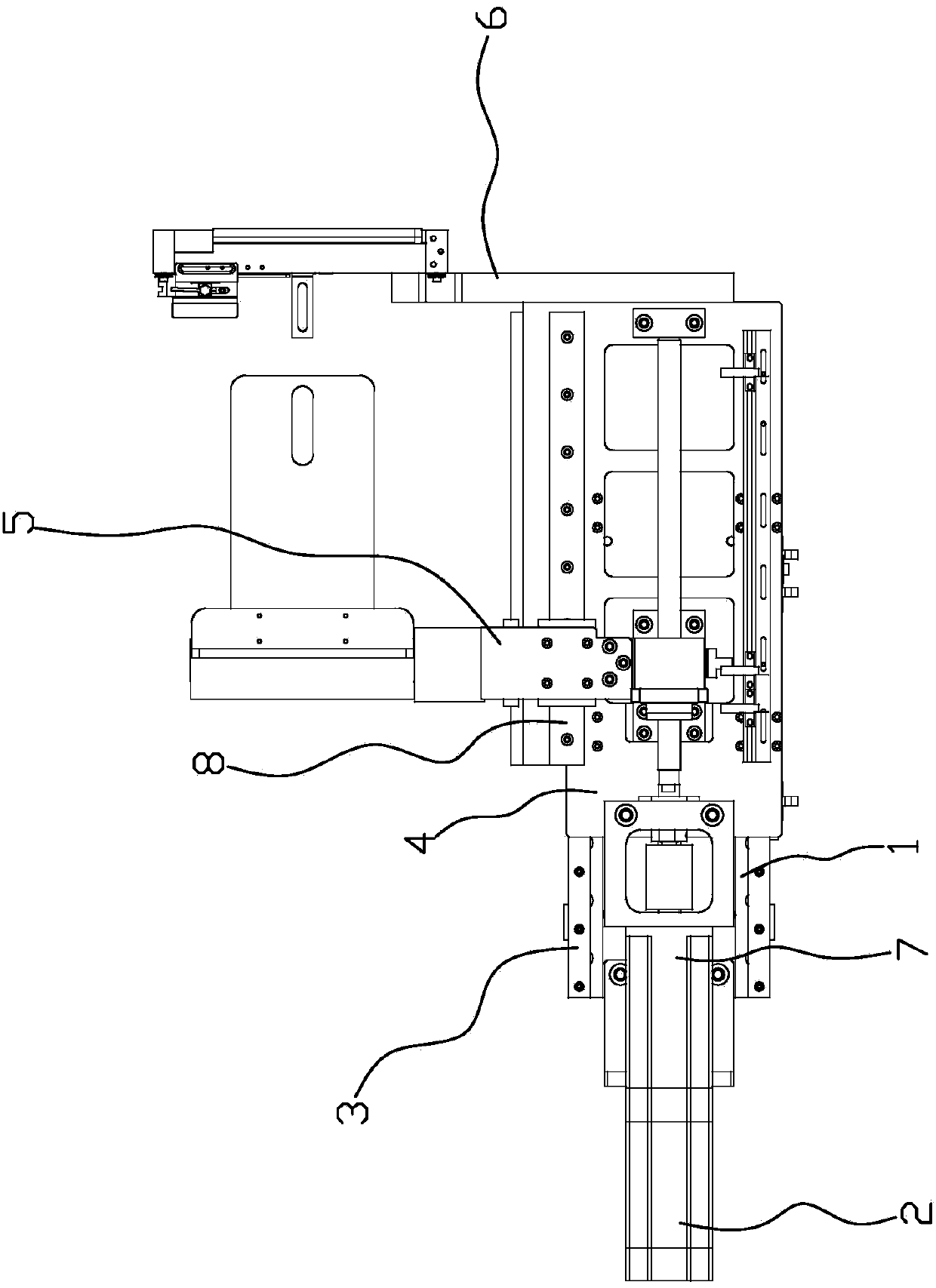

[0017] Reference Figure 1-4 , A pole piece motion cutting assembly of a lithium battery cell processing equipment, comprising a diaphragm encoder and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com