Tree transplanter

A tree transplanting and frame technology, applied in the field of machinery, can solve the problems of affecting the survival rate of tree transplanting, damage to the root system of nearby trees, easy damage to the tree body and tree crown, etc., to save manpower, low labor intensity, and ditching high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

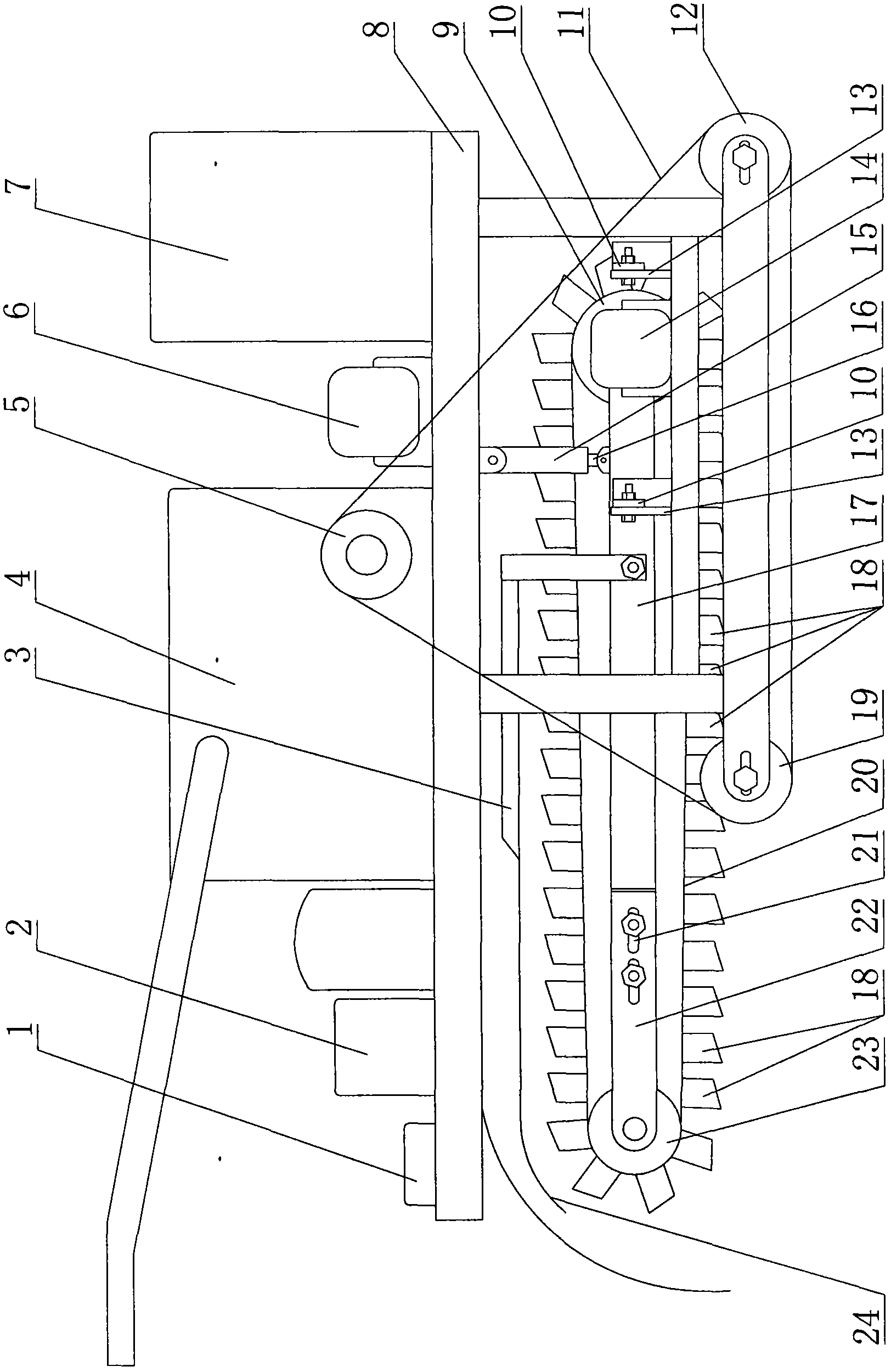

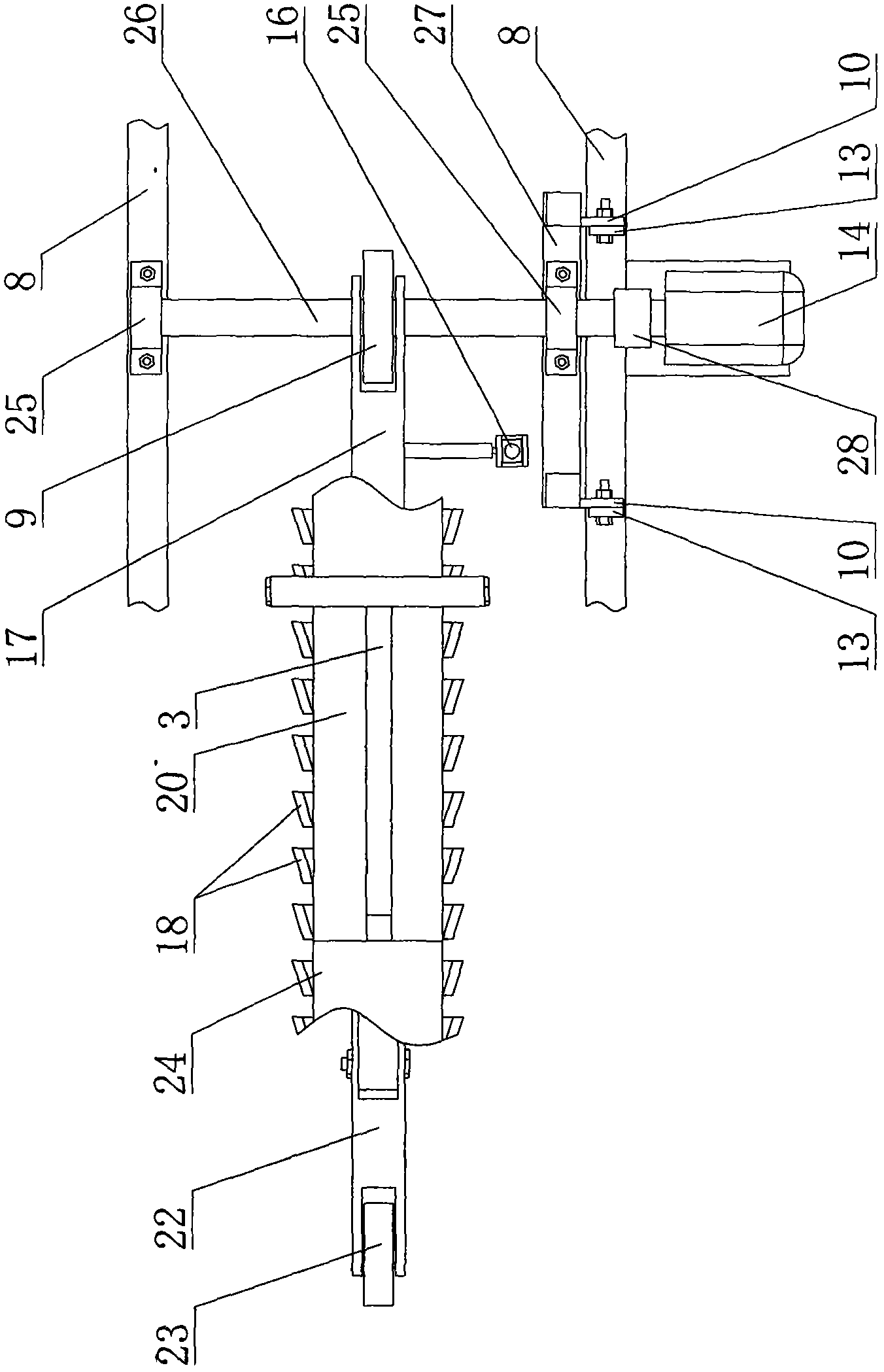

[0022] Embodiment 1: as attached figure 1 And attached figure 2 Shown, tree transplanting machine comprises frame 8, is connected with motor 7, oil tank, oil pump 2, gearbox 4 and traveling mechanism on frame 8, and hydraulic cylinder 15 is installed on frame 8, and the bottom of frame 8 is connected There is a connecting frame 27 that can rotate relative to the frame 8, the connecting frame 27 is connected with a cutting arm, the piston rod 16 of the hydraulic cylinder 15 is hinged with the cutting arm, one end of the cutting arm is provided with a drive wheel 9, and the other end of the cutting arm is provided with The driven wheel 23, the driving wheel 9 and the driven wheel 23 are sheathed with a chain 20, the chain 20 is equipped with a cutting knife 18, and the driving wheel 9 is transmission-connected with a cutting hydraulic motor 14. The hydraulic cylinder 15 and the cutting hydraulic motor 14 are connected with a hydraulic switch device 1 . The hydraulic switch de...

Embodiment 2

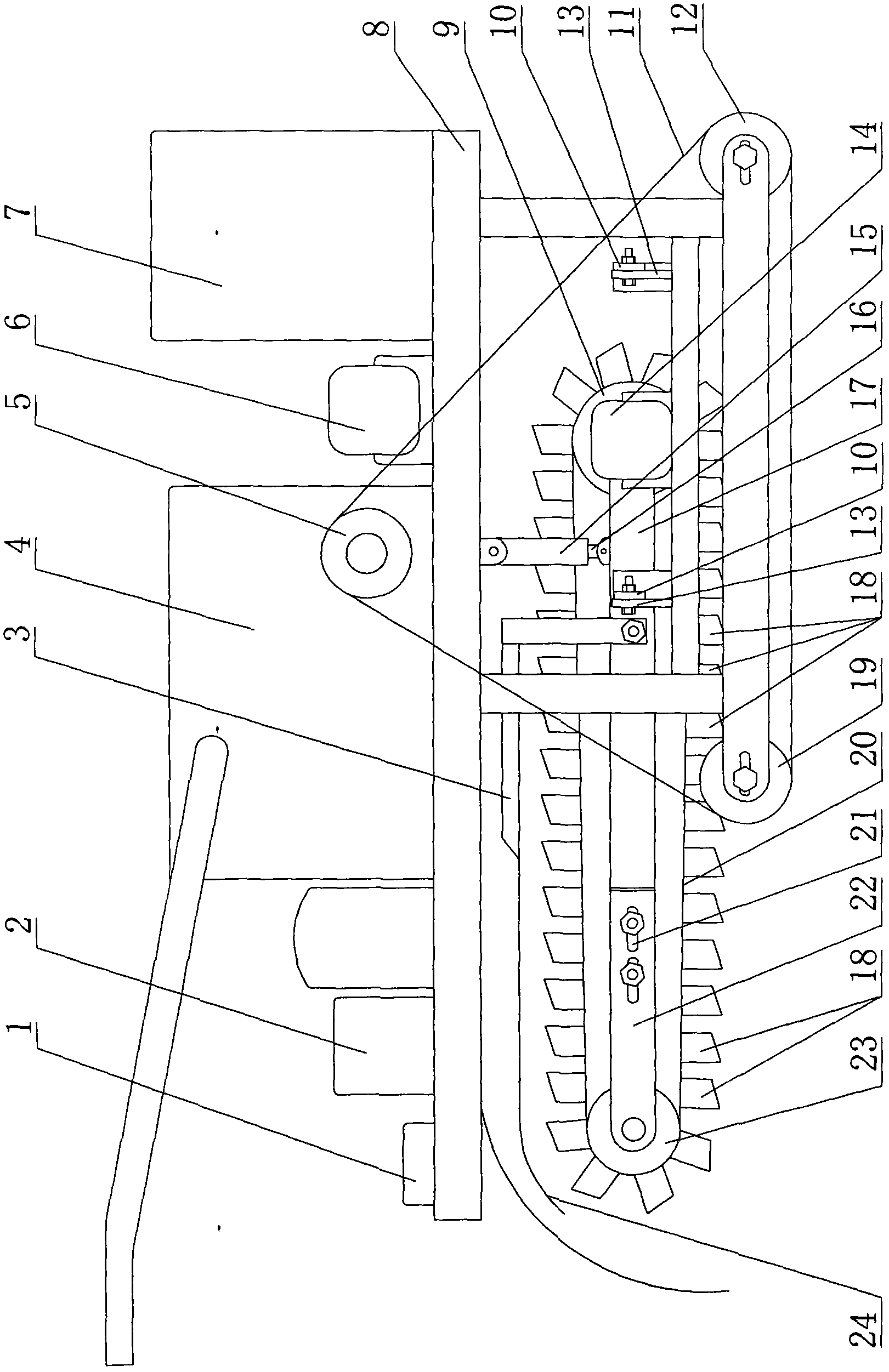

[0029] Embodiment 2: as attached image 3 And attached Figure 4 Shown, tree transplanting machine comprises frame 8, is connected with motor 7, oil tank, oil pump 2, gearbox 4 and traveling mechanism on frame 8, and hydraulic cylinder 15 is installed on frame 8, and the bottom of frame 8 is connected There is a connecting frame 27 that can rotate relative to the frame 8, the connecting frame 27 is connected with a cutting arm, the piston rod 16 of the hydraulic cylinder 15 is hinged with the cutting arm, one end of the cutting arm is provided with a drive wheel 9, and the other end of the cutting arm is provided with The driven wheel 23, the driving wheel 9 and the driven wheel 23 are sheathed with a chain 20, the chain 20 is equipped with a cutting knife 18, and the driving wheel 9 is transmission-connected with a cutting hydraulic motor 14. The hydraulic cylinder 15 and the cutting hydraulic motor 14 are connected with a hydraulic switch device 1 . The hydraulic switch de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com