Aero-engine nozzle deposit carbon removing method

A carbon deposition technology for aero-engines and nozzles, applied in the field of aero-engines, can solve problems such as difficult removal of carbon deposits and economic losses, and achieve the effect of reducing scrap rate and obvious economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

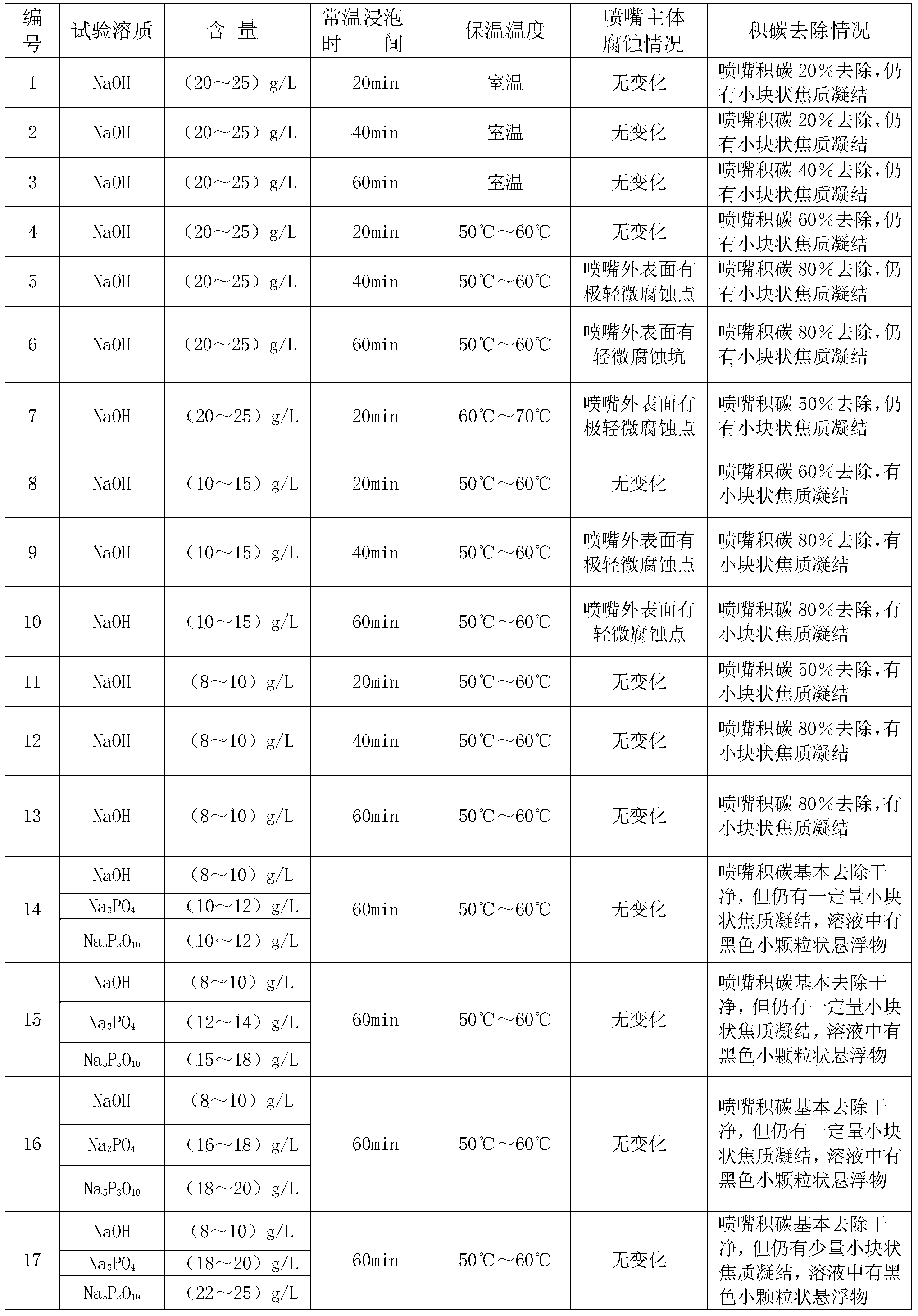

[0032] This embodiment is a comparison test for two nozzles of a certain type of aero-engine that have produced carbon deposits, one using ultrasonic cleaning, and the other using the method of the present invention to remove carbon deposits.

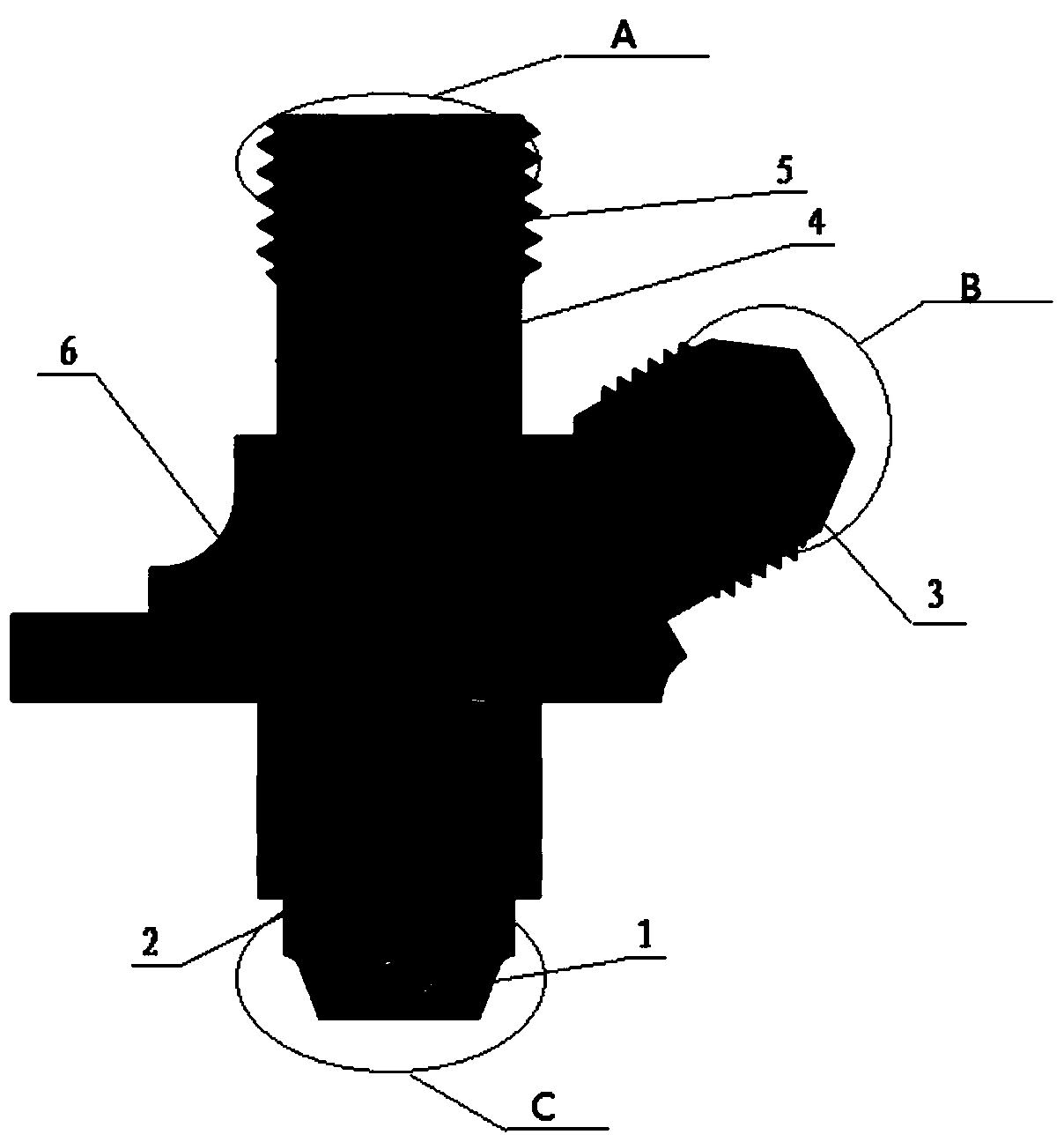

[0033] The aircraft engine nozzle such as figure 1 As shown, it consists of starting nozzle 1, nozzle body 2, throttle nozzle 3, oil filter 4, collar 5 and nozzle seat 6.

[0034] Use the starting nozzle flow tester (special for non-standard) to test the flow of the two engine nozzles respectively, the flow of the first nozzle is 5.4L / h, the flow of the second nozzle is 4.8L / h, the flow of the two nozzles The flow rate is close, and the carbon deposits are relatively serious, which cannot meet the requirements of aero-engines, and cannot continue to be used without removing the carbon deposits.

[0035] The first engine nozzle was cleaned with an ultrasonic cleaner for 1 hour, and then tested with a start-up nozzle flow tester. The flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com