Multipurpose cross wedge rolling die

A cross-wedge rolling and cross-wedge rolling mill technology, applied in the field of molds, can solve problems that affect the development of enterprises, increase production costs and development cycles of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing, the multi-purpose cross wedge rolling die of the present invention will be further described;

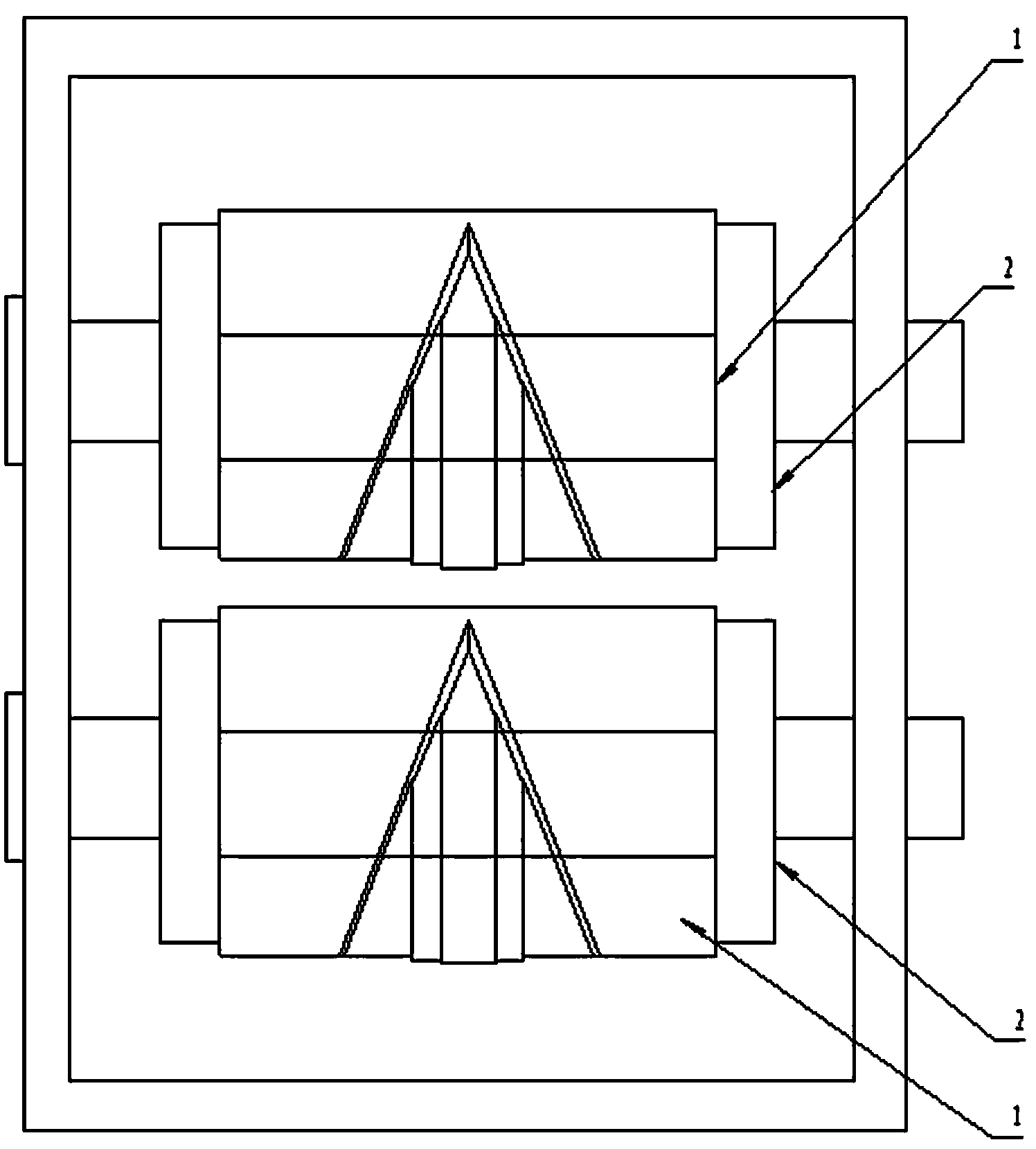

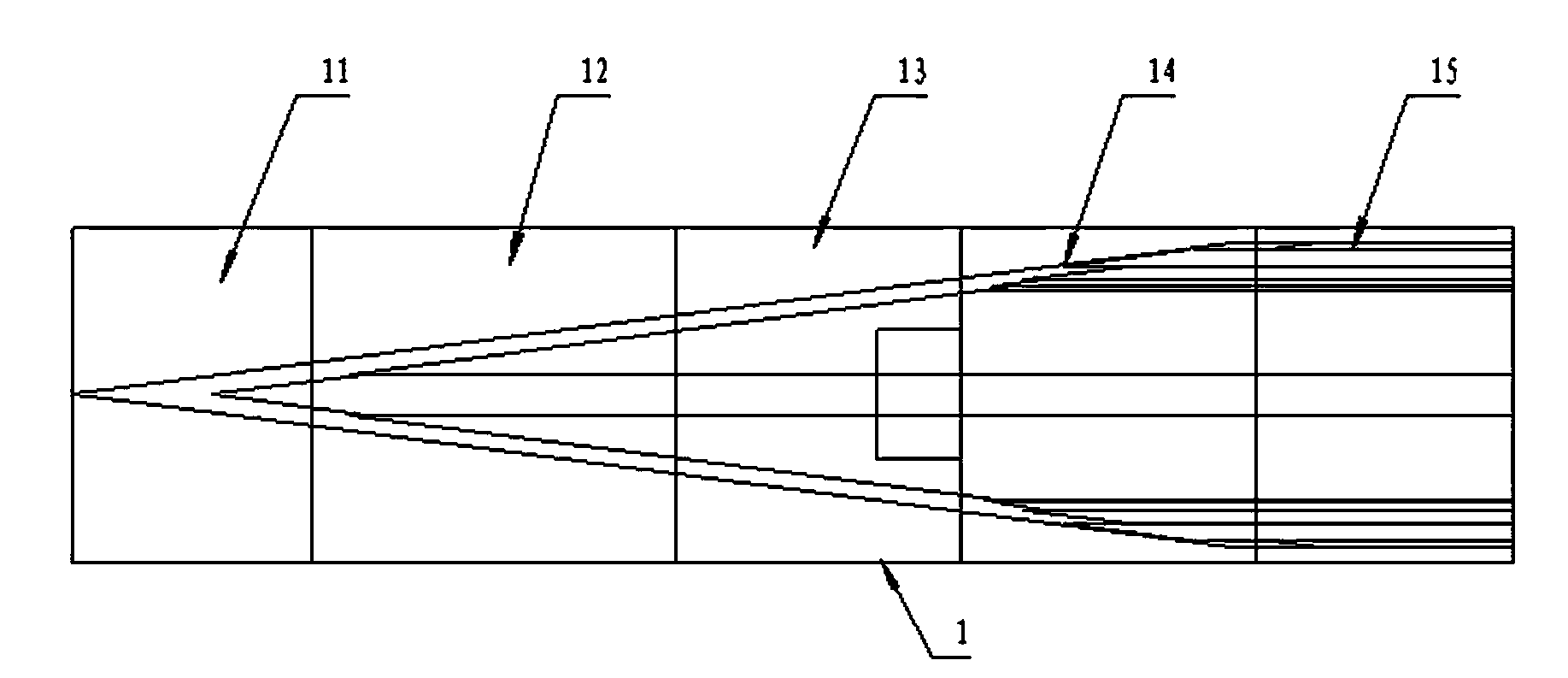

[0010] Depend on figure 1 , figure 2 It can be seen that a cross wedge rolling die of the present invention includes upper and lower die bodies 1, and the upper and lower die bodies 1 are composed of several modules, and each module is movably installed on the upper and lower sides of the cross wedge rolling mill. on work roll 2.

[0011] When the present invention is used, the number of modules of the upper and lower mold bodies 1 is determined according to the actual size of the shaft parts to be processed, and then each module is installed on the upper and lower work rolls 2 of the cross wedge rolling mill to form a complete The upper and lower mold bodies 1 can produce shafts of different sizes.

[0012] The technology of this embodiment is mainly solved by the following technical solutions: the replaceable parts of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com