Double feeding system of numerical control honing machine

A feed system and honing machine technology, which is applied to the parts of grinding machine tools, grinding drive devices, grinding/polishing equipment, etc., can solve the problems of inaccurate control of the honing process and low feeding efficiency, and achieve improved progress. Give the effect of low efficiency and achieve precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

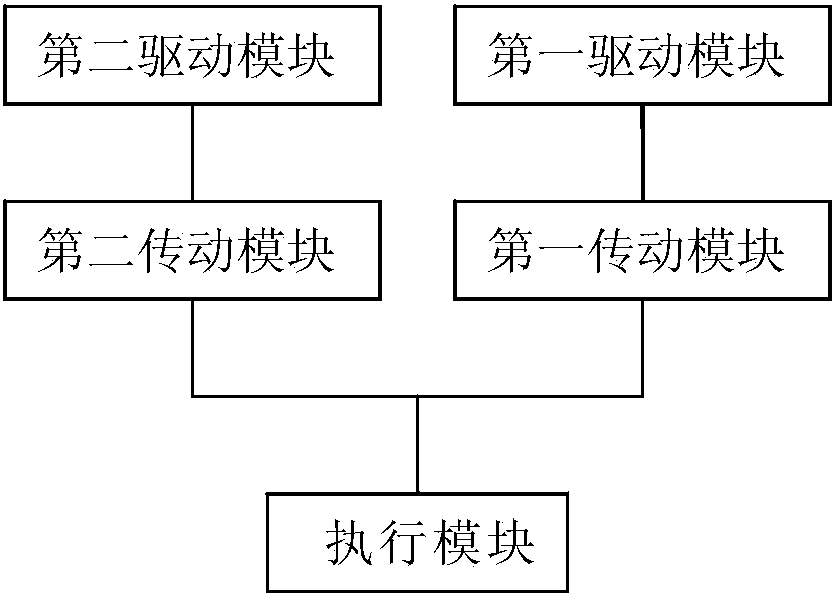

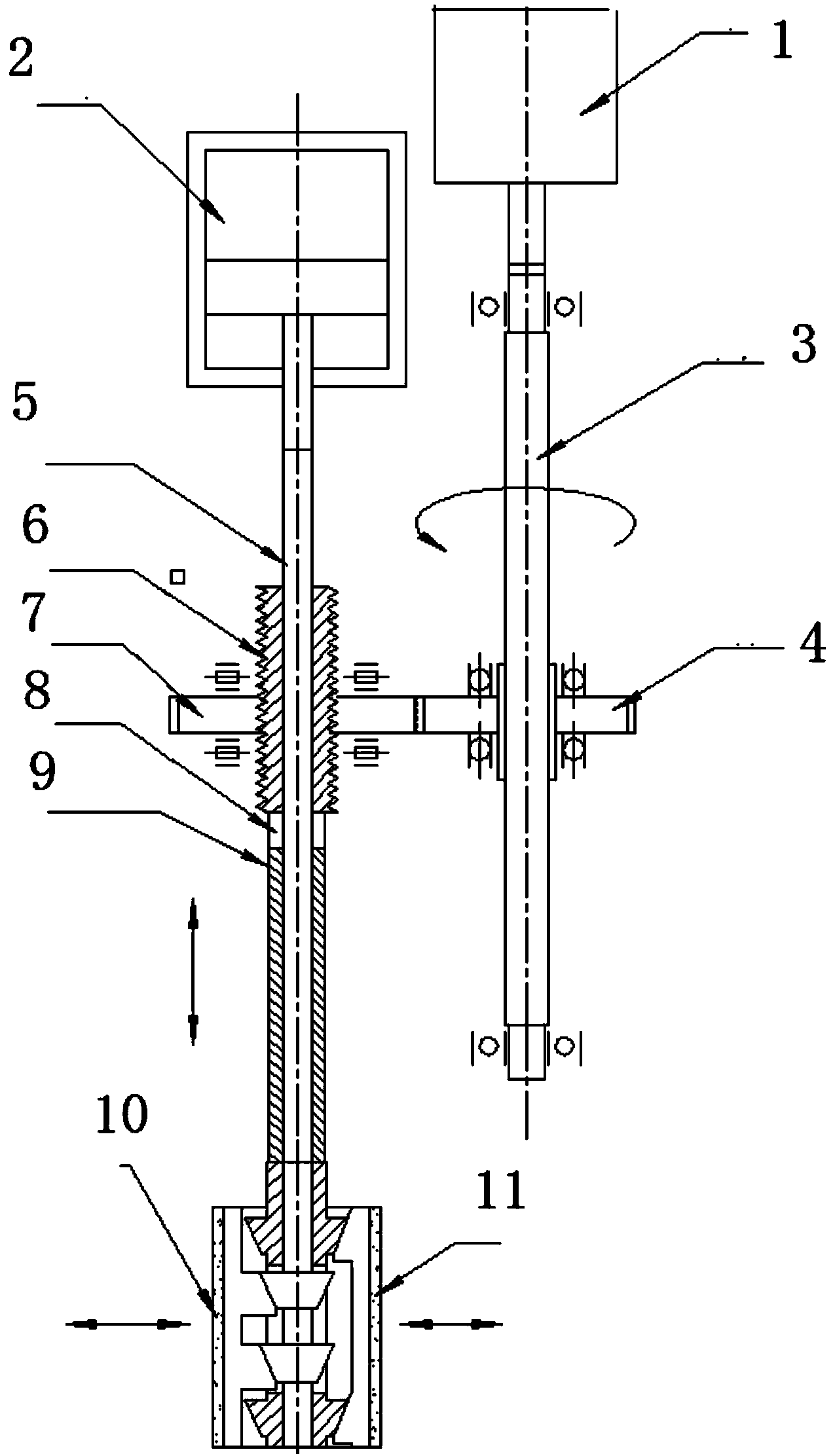

[0018] like figure 2 As shown, the first drive module is a servo motor 1, the second drive module is a feed cylinder 2; the execution module is a honing head, and the honing head includes a platform honing bar 10 and a coarse honing bar 11, the platform honing bar 10 and the second honing bar The two transmission modules are connected, and the coarse honing bar 11 is connected with the first transmission module; the first transmission module includes a ball spline 3, a first gear 4, a ball screw 6, a second gear 7, a force sensor 8 and an electromechanical push rod 9. The ball spline 6 is respectively connected with the first driving module and the first gear 4, the second gear 7 is connected with the first gear, the ball screw 6 is connected with the force sensor 8, and the electromechanical ejector rod 9 is respectively connected with the force sensor 8 and The executive module is connected; the second transmission module is the hydraulic ejector rod 5 .

[0019] Electro-m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com