Marine electric mooring winch

An electric and mooring technology, applied in hoisting devices, clockwork mechanisms, etc., can solve the problems of large space occupied by oil pump units, oil pollution, and increased manufacturing costs, and achieve compact structure, low cost, and high manufacturing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

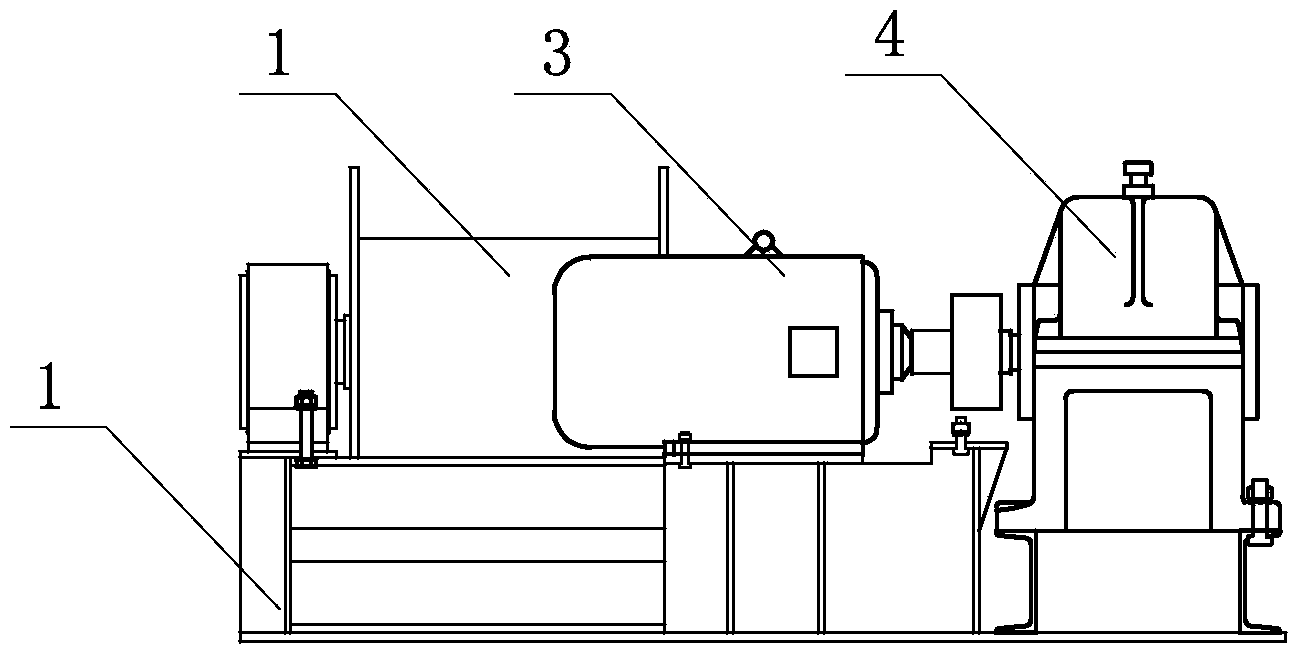

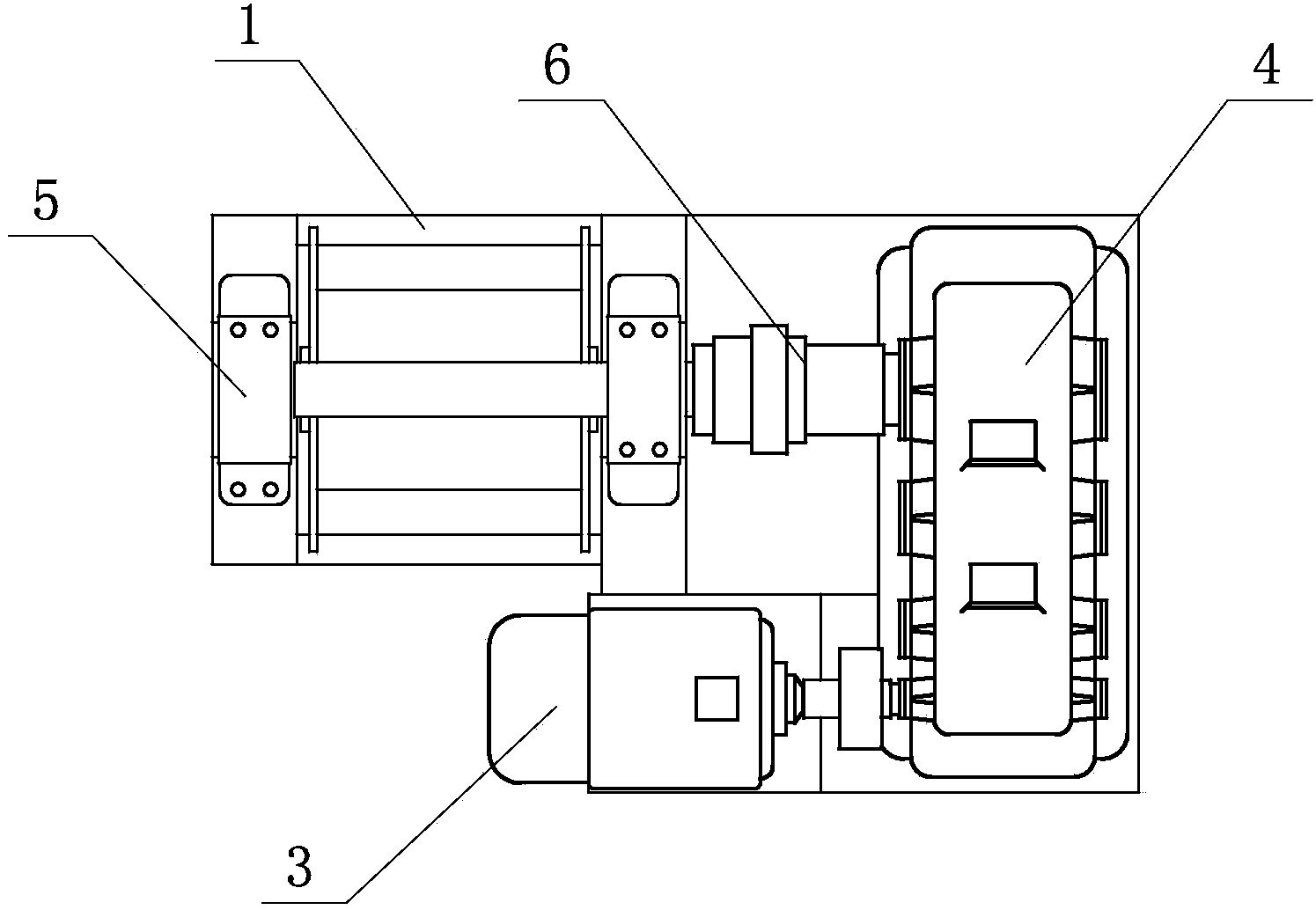

[0014] Such as figure 1 with figure 2 As shown, the marine electric mooring winch of this embodiment includes a base 1, a rope storage reel 2 is installed on one end of the base 1, and a frequency conversion motor 3 is installed on the lower part of the other end of the base 1, and the output end of the frequency conversion motor 3 is connected to the deceleration Box 4, the output end of reduction box 4 is connected to the rotating shaft of rope storage reel 2 through coupling 6;

[0015] The output shaft of the variable frequency motor 3 is parallel to the output shaft of the reduction box 4 .

[0016] The base 1 of the present invention is installed on the deck of the bow or stern of the ship,

[0017] During actual use, the forward rotation and reverse rotation of the rope storage drum 2 are controlled through the function of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com