Intelligent sensing method and system for electroplating line current abnormity

An abnormal current and induction system technology, applied in electrolysis process, electrolysis components, cells, etc., can solve problems such as inability to fully inspect, quality incidents, copper plating of A material number, etc., to achieve intelligent detection and improve the reliability of electroplating Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

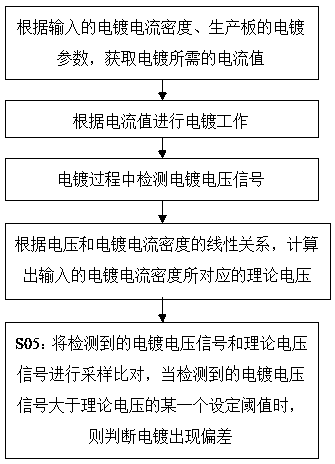

[0047] Such as figure 1 As shown, it is a flow chart of a specific embodiment of an intelligent sensing method for an abnormal current in an electroplating line according to the present invention. join figure 1In this specific embodiment, an abnormal intelligent sensing method for an electroplating line current specifically includes:

[0048] S01: Obtain the current value required for electroplating according to the input electroplating current density and the electroplating parameters of the production board; it specifically includes:

[0049] S011: Calculate the theoretical current required for electroplating according to the input electroplating current density and the electroplating parameters of the production board; wherein, the electroplating parameters of the production board include the area of the production board, the number of production boards, etc.

[0050] S012: After adjusting and verifying the theoretical current, obtain the current value required for elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com